Low-Volume Injection Molding: An In-depth Overview

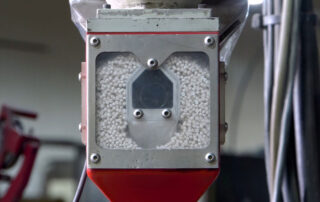

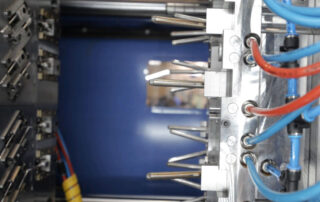

In the world of manufacturing, production volume often dictates the methods and processes that companies use. Traditional injection molding has been a stalwart for large-scale production. However, what happens when you need fewer parts with the same precision and quality? This is where low-volume injection molding (LVIM) comes into [...]