Molding a Healthier World: The Power of Medical Injection Molding

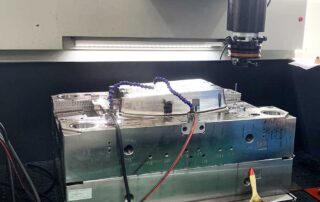

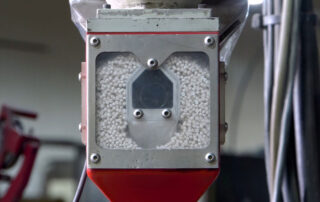

Medical Injection Molding is a specialized manufacturing process that produces intricate and high-precision plastic components used in the medical industry. It's a process that goes far beyond just creating parts; it saves lives, enhances patient care, and enables medical advancements. Behind the scenes, a remarkable manufacturing process plays a [...]