Senses China All-in-one services

Plastic Injection Molding Service China

From initial plastic design to final production, our Custom Plastic Injection Molding Services at Senses ensures high-quality, competitively priced injection molded parts with a swift turnaround time. Besides, we offer complimentary expert consultation for every injection molding order, which includes guidance on mold design, choices of materials & surface finishes for your specific applications, and shipping options.

Plastic injection molding is a manufacturing process where heated and liquefied plastic is injected into a pre-designed mold. Once the plastic cools and solidifies, it takes the shape of the mold, producing a part with high precision and accuracy.

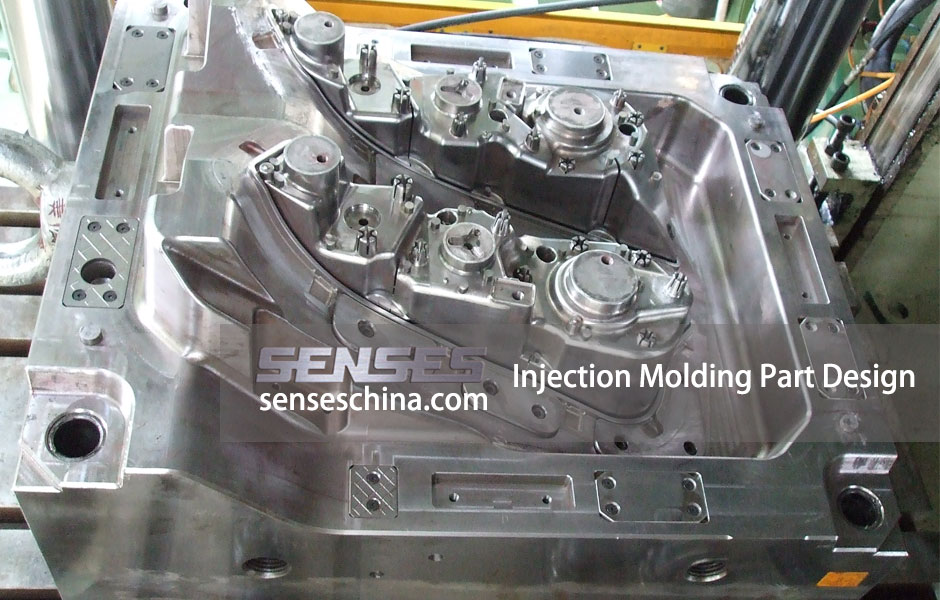

Production Tooling is the linchpin of mass manufacturing, ensuring that every product adheres to stringent quality standards. We bridge the gap between conceptual designs and high-volume tangible outputs, guaranteeing efficiency, consistency, and top-tier quality in every production run.

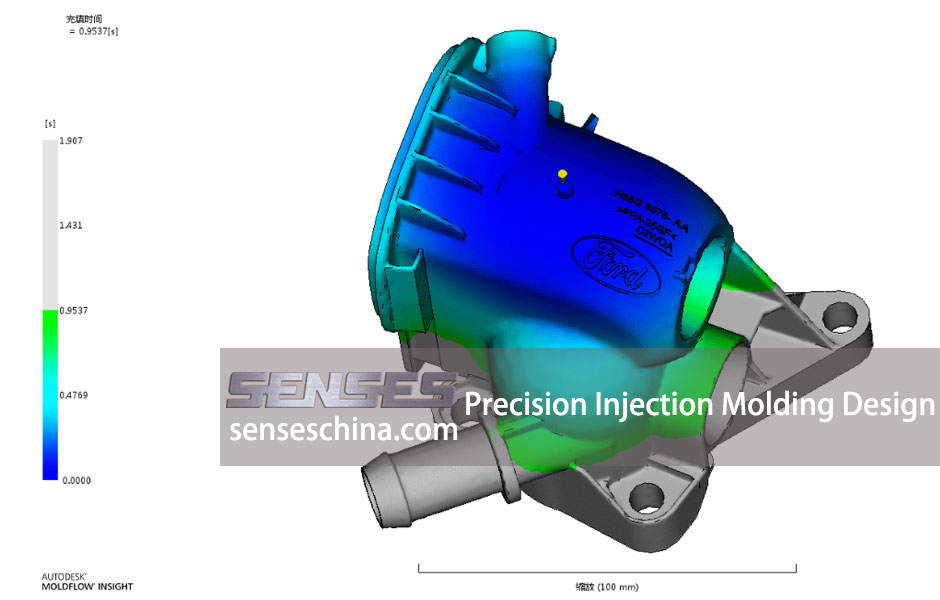

At Senses, we offer comprehensive Design and R&D services to assist in bringing your product ideas to fruition. Our team of seasoned engineers and designers work closely with you, utilizing the latest CAD/CAM technology and simulation tools to refine and optimize your design for injection molding.

Injection molding service with Senses

Our facilities, combined with our network of trusted manufacturing partners, enable us to cater to both low-volume and large-volume projects. Additionally, our commitment to quality assurance, timely delivery, and excellent customer service make us a trusted partner in your manufacturing journey. Contact us today for a free quote and discover how we can bring your vision to life.

Explore More Molding Opportunities with Senses

Overmolding Service

Overmolding is an advanced injection molding process where a single part is created using two or more different materials in combination. Typically, the first material, known as the substrate, is partially or fully covered by subsequent materials during the manufacturing process. This can greatly enhance the product’s features, such as improving grip, providing vibration dampening, enhancing aesthetics, adding flexibility or adding color contrasts.

Insert Molding Service

Insert molding is a versatile, efficient process where an insert—typically made of metal—is placed into the injection molding machine and then plastic is injected around it. This creates a single molded plastic piece that’s reinforced by the insert. Our insert molding service provides an integrated approach to product design and production. We’re capable of producing a wide array of complex insert-molded parts that ensure superior strength, weight reduction, and part reliability.

Liquid Silicone Rubber(LSR) Molding Service

Liquid silicone rubber molding is a specialized process used to create durable, flexible parts with excellent temperature, chemical, and electrical resistance. Our liquid silicone rubber molding service offers custom solutions for industries ranging from medical to automotive, leveraging our advanced equipment and extensive expertise.

Surface Finishes of Injection Molding

Senses provides a wide array of finish options for injection molded parts, including SPI finishes and Mold-Tech and VDI techniques. Our offerings span from glossy, polished finishes to matte surfaces and textured components, allowing for complete customization based on your project requirements. Learm more

Glossy

Semi-Glossy

Matte

Textured

SPI-A1

SPI-A2

SPI-A3

SPI-B1

SPI-B2

SPI-B3

SPI-C1

SPI-C2

SPI-C3

SPI-D1

SPI-D2

SPI-D3

Injection Molding Projects For Senses

Feel free to browse our gallery to gain a deeper understanding of our capabilities and services. If you have any questions or need more information, please don’t hesitate to contact us.

Why Choose Senses for Plastic Injection Molding

Choosing the right partner for your injection molding projects is critical to ensuring high-quality results, and we believe we are that partner you’re looking for. Explore the unique benefits that Senses provides for injection molding services.

We continually strive to improve our processes and deliver consistently high-quality products to our clients.

What is Injection Molding?

Injection Moulding – an overview

Injection molding is a highly versatile manufacturing process used to fabricate parts by injecting molten material into a mold. The process involves the use of an injection molding machine, raw plastic material, and a mold. The plastic is melted in the injection molding machine and then injected into the mold, where it cools and solidifies into the final part.

This process is extensively used due to its ability to produce items with complex geometries at a high production rate, and it’s especially cost-effective when creating large quantities of identical parts. It’s used in a vast range of industries, including automotive, aerospace, medical, and consumer goods, to create a myriad of products we use daily.

Benefits of Injection Molding

Injection molding is a highly efficient manufacturing technique, especially suitable for mass production. Its rapid and precise nature allows it to create parts of complex shapes with extremely high precision, even up to 0.002 inches (0.05mm). Due to the high level of automation in this process, labor costs can be significantly reduced.

Moreover, injection molding offers a wide range of material options, such as hard plastics, thermoplastics, and rubber. The process also allows for the addition of various colors and additives to meet specific appearance and performance requirements. When it comes to waste management, injection molding has its own set of advantages. Waste generated during production can be reground and reused, making the process both waste-efficient and environmentally friendly.

Injection molding is a trustworthy, efficient, and adaptable manufacturing technique that can meet a variety of product needs and provide a wide range of design and production solutions.

Injection molding has a wide range of applications, covering almost all industrial sectors. Whether it’s automotive parts, medical devices, electronic products, household products, or even toys, you can find the application of injection molding. For example, in car manufacturing, interiors, dashboards, various buttons, and many structural parts can be made through injection molding.

In the medical field, injection molding is used to manufacture surgical devices, diagnostic equipment, medicine bottle caps, and other medical devices. In addition, most plastic bottles, containers, electronic casings, and some daily plastic products are manufactured through injection molding. The widespread application of this technology has made it an integral part of our lives.

Injection Molding FAQs

Plastic Injection Molding Service China

Custom Plastic Knob Injection Molding

Plastic knobs may seem small, but they play a big role in many products we use every day — from home appliances and cars to electronic devices and industrial machines. These knobs need to [...]

Precision Injection Molds Custom

Whether you're producing medical devices, automotive parts, or everyday consumer products, the quality of your plastic components can make or break your success. That’s where precision injection molds custom come in — they are [...]

Automotive Plastic Molding Company

As a trusted automotive plastic molding company, Senses specializes in providing high-quality injection molding solutions tailored to the needs of the automotive industry. From interior components and dashboard panels to exterior lighting housings and [...]