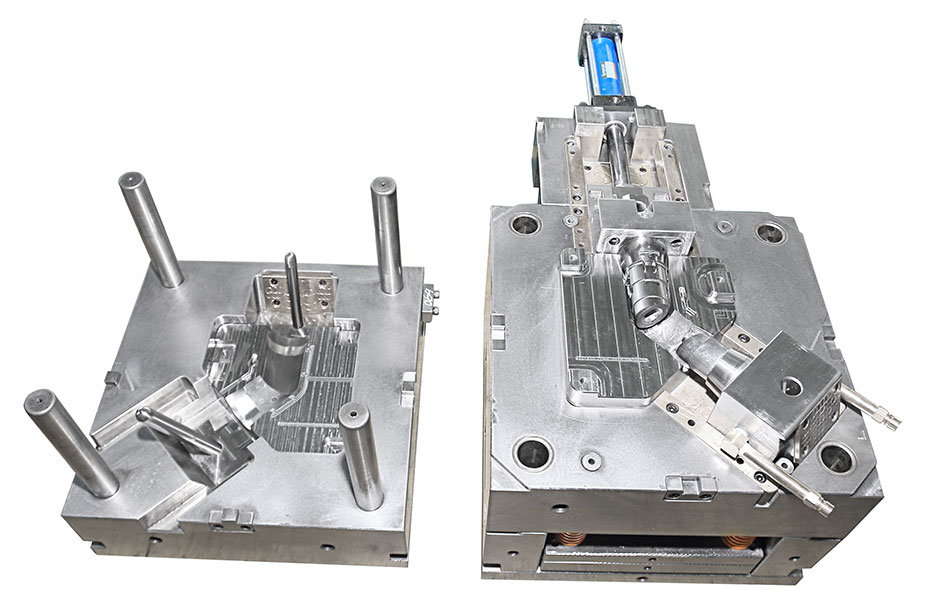

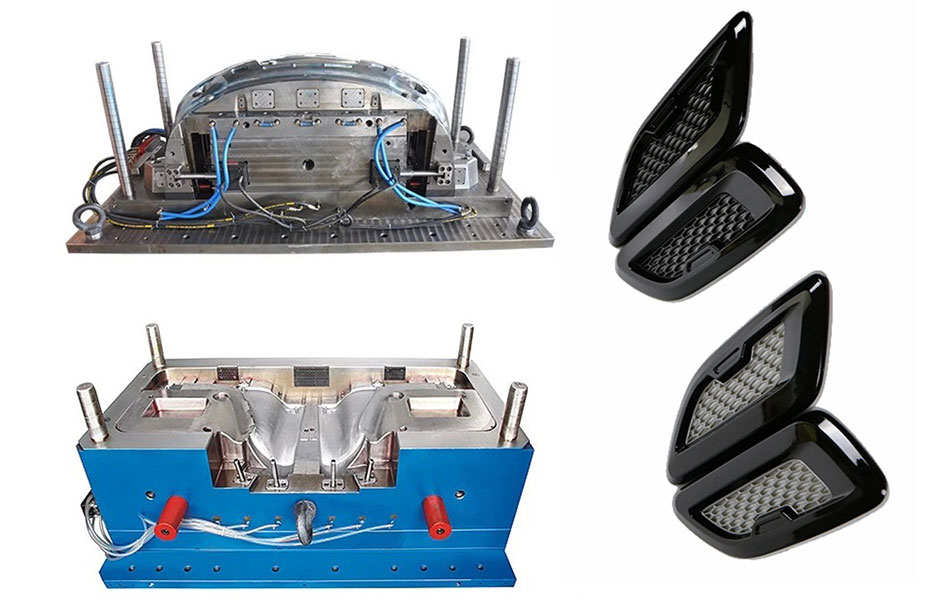

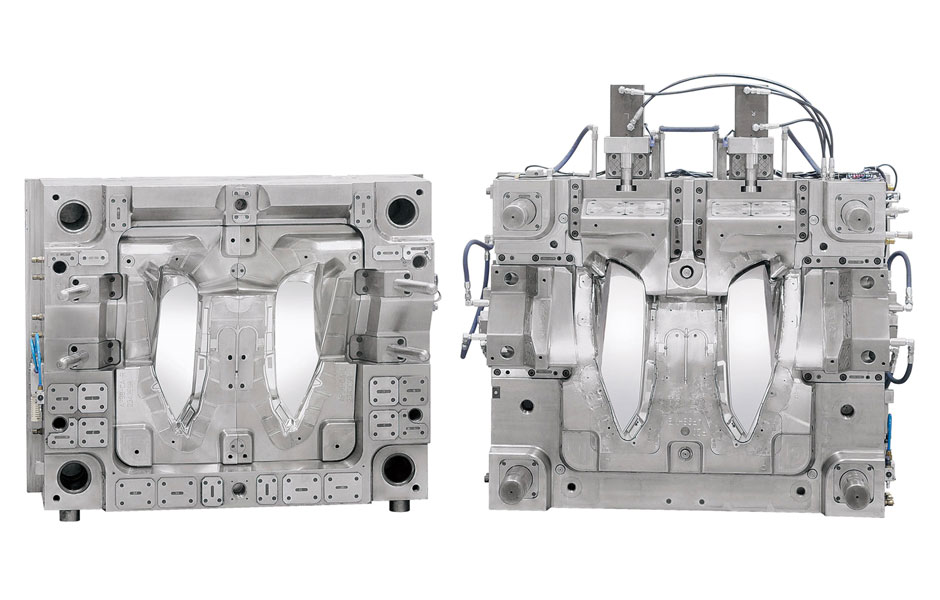

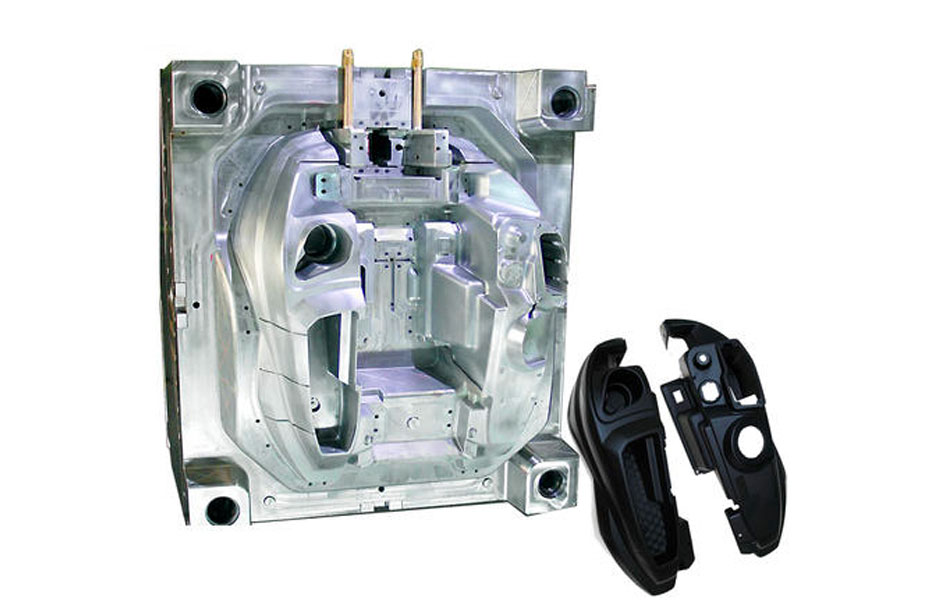

Automotive Injection Mould

Plastic mold is the mother of industry, and it is required by almost all of the product components in modern manufacturing. Injection mould is important process equipment for the production of the various industrial products. With the rapid development of the plastics industry and the promotion, application of plastic product in the aviation, aerospace, electronics, machinery, shipbuilding and automotive industries, the requirement of product to molds are becoming more and higher.

Senses is a professional mold manufacturer located in Chang’an Dongguan China, which are specialized in Automotive parts, Consumer Electronics, Medical Care, Household mold making. Senses ambitioned to be one of the best supplier of one stop for plastic mold making, injection molding for Automobile and other industrial; Based on this Target, we accumulated extensive experience on precision Auto mold & injection molding.

Advantages of Injection Molding for Automotive Applications

Repeatability

In the automotive industry, repeatability—or the ability to consistently produce identical parts—is crucial. Because injection molding typically relies on robust metal molds, the final plastic parts produced using the mold are practically identical. There are factors that come into play with injection molding, but if the mold is well designed and made, injection molding is a highly repeatable process.

Scale and cost

Though the injection mold-making process is expensive (as well as the cost of the mold), injection molding is a highly scalable process whose overall cost decreases the more parts are made. For mass production applications, injection molding is thus beneficial to the manufacturer. For anything less than mass production, however, injection molding tooling costs may curb the cost efficiency of the process.

Material availability

A significant benefit of using injection molding for automotive production is the wide range of rigid, flexible and rubber plastics the process is compatible with. In the automotive industry, a range of different polymers are used for various applications, including ABS, polypropylene, acrylic, acetal, nylon, polycarbonate and more.

High precision and surface finish

Injection molding is ideal for producing plastic parts with relatively simple geometries and results in parts with high surface finish quality. Manufacturers have many finish options when producing parts, including various surface textures—such as glossy, rough or matte—which are applied directly to the mold rather than the molded part. Different plastic materials also influence the final surface finish.

Automotive Injection Mould

Case Studies of Automotive Parts

If you’re ready to start your next project, upload your product design information for a competitive injection molding quote today.