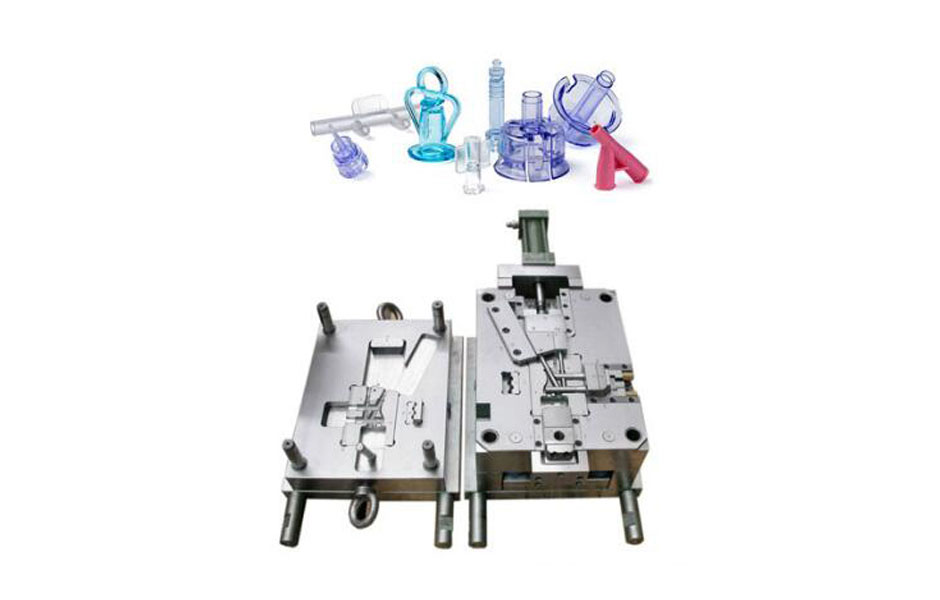

Medical Device Injection Mould

Plastic has a very important application in the medical field, and injection products are the most widely used. Medical injection molding products have extremely demanding requirements for cleanliness. Meanwhile, the precision, thinning and high productivity requirements of medical injection molding products all pose challenges to the matching of production units such as injection molding machines, molds and manipulators.

Since medical device plastics provide increased versatility and can be combined with metal to create enhanced medical product attributes, medical grade plastics have become the preferred material for numerous types of electronic medical devices. Some of the advantages that medical injection molding companies can provide, include:

- Improved ergonomics

- Reduced weight

- Increased functionality

- Lower cost

- Decreased burden of sterilization

Senses located in Dongguan China, is an experienced factory focusing on designing and manufacturing plastic injection molds and molded parts for disposable medical components, medical devices etc. We can offer high quality tools with reasonable cost.