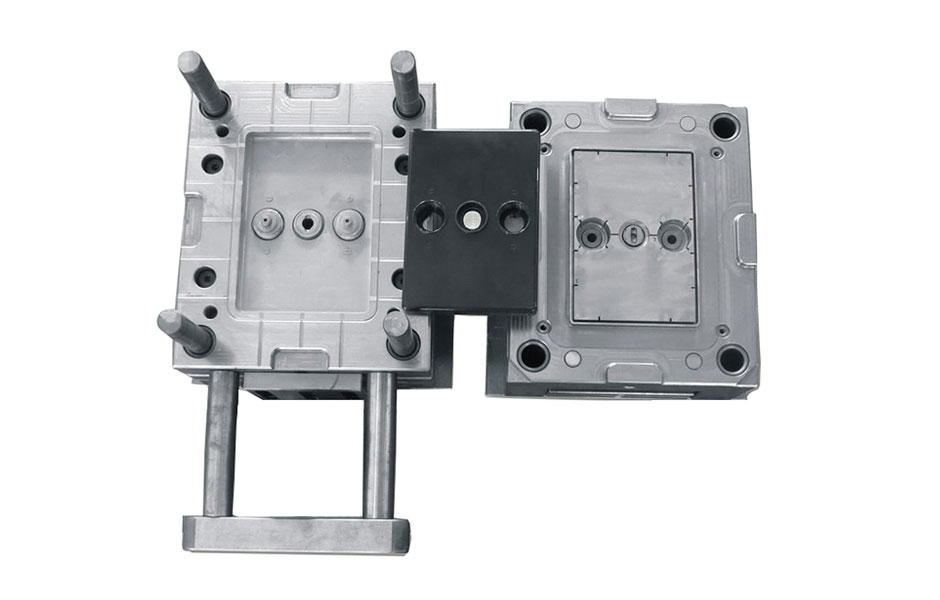

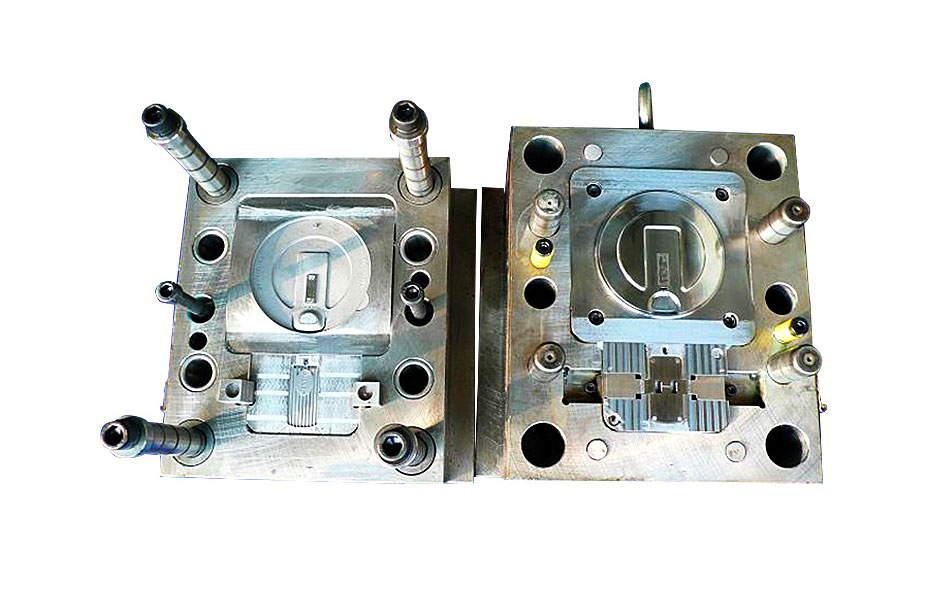

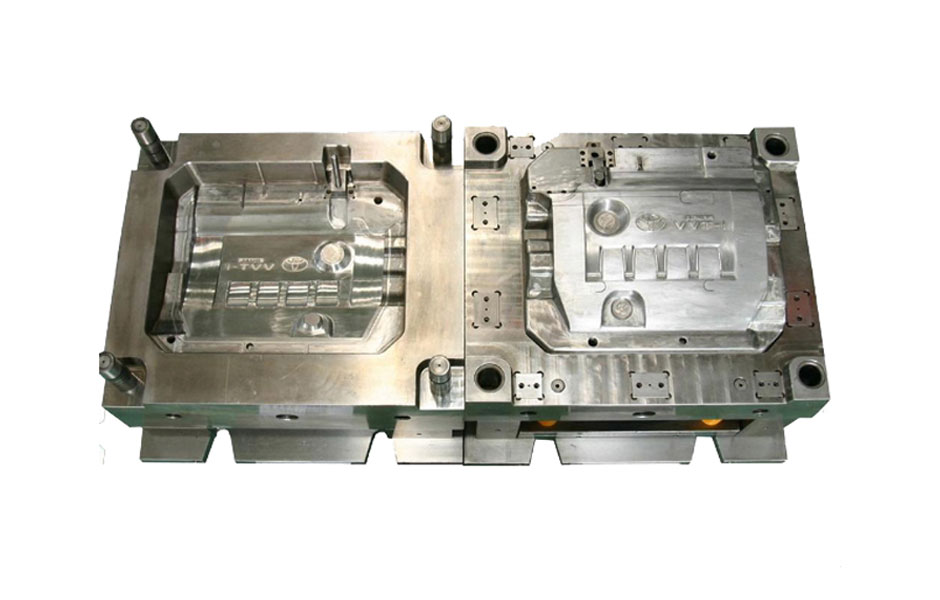

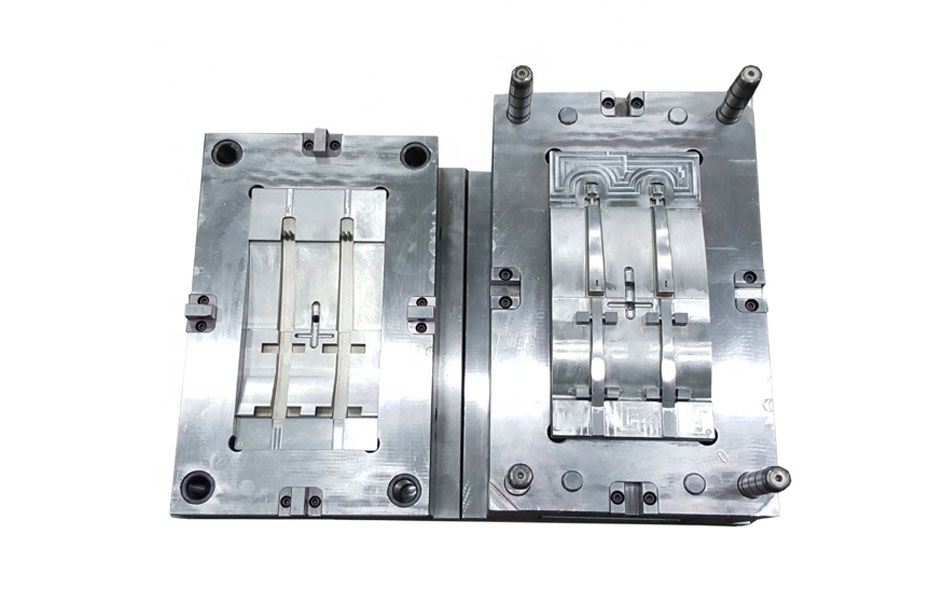

Electronic Parts Injection Mould

Senses is an injection molding manufacturer with expertise in designing molds for manufacturability. We understand that you have designed your products to perfection, while our experience in producing cost-effective plastic injection solutions makes your products even more perfect. We employ our industry know-how to simplify the tool design where possible, aiming to ensure that ultimately what we offer is a flexible, tailored solution which will allow us to create real injection molded parts in a rapid lead time.

Keeping up with all of the changes in electronics can be incredibly difficult, but that is why it is so important to have the right molds for different electronic needs. If you have a highly complicated electronic subassembly part, for example, we have the experience to produce these intricate molds cost-effectively and in a reasonable time. Plastic parts for electronic products are normally small, so nowhere is precision more critical than in electronic components.

Combining our excellent mold design & making capability with the most state-of-the-art injection molding machines, Senses can provide accurate plastic parts for your electronic products, large or small. That is what makes Senses an ideal choice for your electronic molds.

From Concept to Product in as Fast as 5 steps:

- Provide us your 2D and 3d drawings for quotation.

- DFM(Design for Manufacturing), our experienced engineers produce analysis reports on production limitations and possible solutions to them based on review of your design.

- After DFM approve, we will provide 2D and 3d mold drawing for approval.

- Mold Manufacturing, once mold drawings are approved, we will start manufacturing and finish them in reasonable time. We will also update timing schedules each week for your reference.

- Tool trials & samples inspection & delivery.