Capacity to provide integrated service

With a team of premier manufacturing sites, we have capacities to manage even the largest project, from beginning to end, which includes design, tooling, manufacturing, packaging, assembly, drop-shipping, etc, whether it is metal fabrication or plastics injection molding or a combination.

And we are able to respond to market demands and fluctuations and not be constrained by manufacturing capacity.

We expect to be your single source for a variety of services so as to reduce your paperwork and administrative load and help with your vendor reduction programs.

CMM Testing Center

Manufacturing Line

Updated equipments and skilled staff

Acquainted with the line and adequate in fund, we have introduced various sophisticated machines including the most advanced ones from Japan, Germany and the USA.

We have managed to keep a stable, well-educated staff, in which more than 50 engineers and technicians are included. Growing with SENSES, they get a series of trainings and, therefore, are always proficient in operating updated machines introduced by the company.

Well-built organization

“Best practices” is our guideline in transaction. Our unique “Technology and costing team” helps us coordinate the service procedures, while “design for manufacturability” solution can fundamentally save money and time for you. Additionally, EDI trade solutions help us get rid of redundant paperwork and improve efficiency of transaction, which will save money and time for us and, consequently, reduce your product cost.

Senses has capabilities to offer, at comparative price in time, integrated solutions from design, through production to delivery.

Shown, for your reference, are our capabilities :

(not limited to these) Engineering/Technical Product

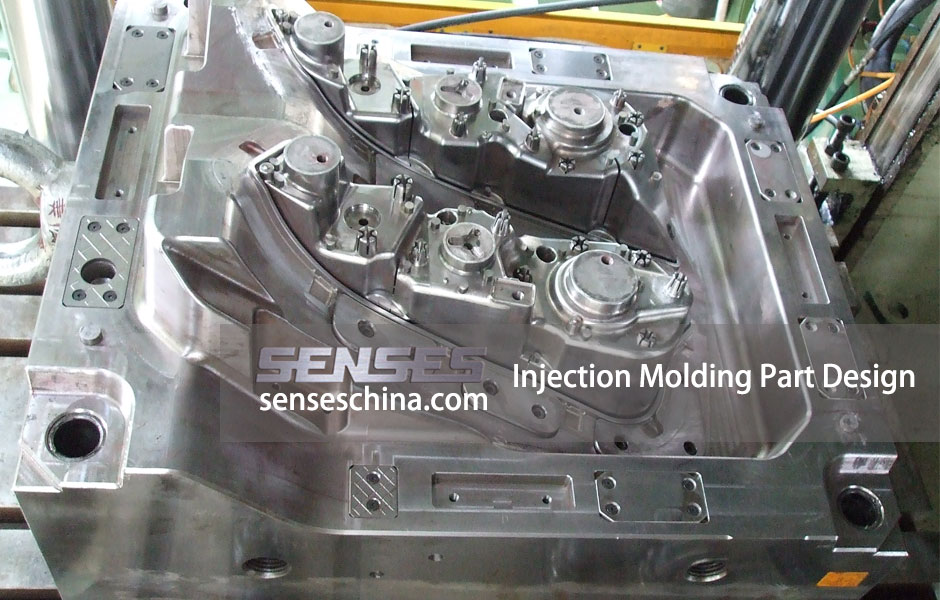

- Design/Mold Design

- Mold Flow Analysis

- Project Management

- Supplier Managed Inventory

- Design for Manufacturing

- Value Analysis Mold Build

- Molds to 2000 Ton

- Complex Surfaces

- Assembly Fixtures

- Hot-Runner Capability Technical Injection Molding

- 20 Through 2000 Ton Injection Molding Presses

- Structural Foam

- Small Precision and Large Cosmetic

- Gas Counter Pressure

- High-Pressure Thinwall

- Robotic and Automated Pick and Place Secondary Operations

- CNC Machining

- Sonic Welding

- Heat Staking

- Hot Stamping

- Pad Printing

- Solvent Bonding Finishing

- Water Based Paint

- Powder Coat Paint

- EMI/RFI Spray on Shielding