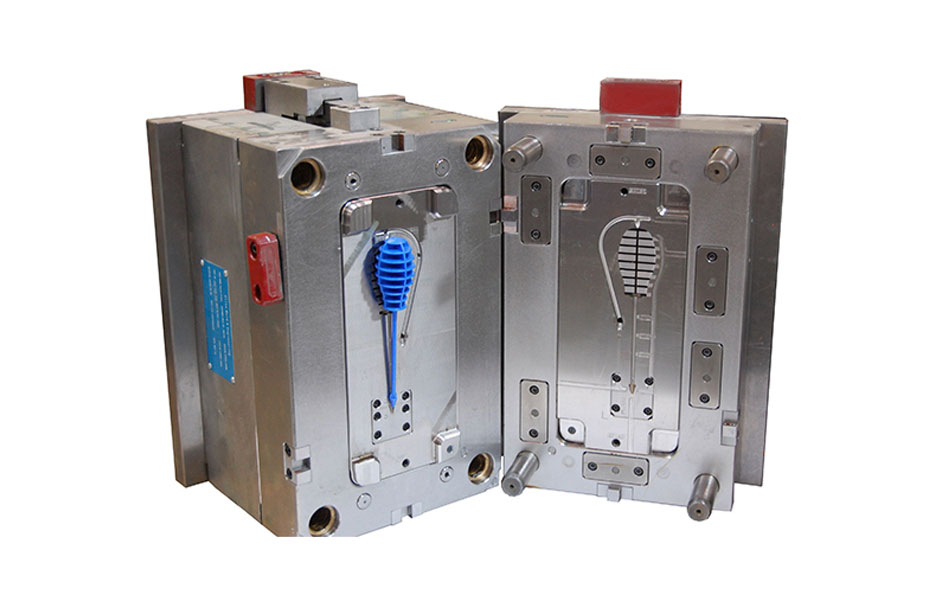

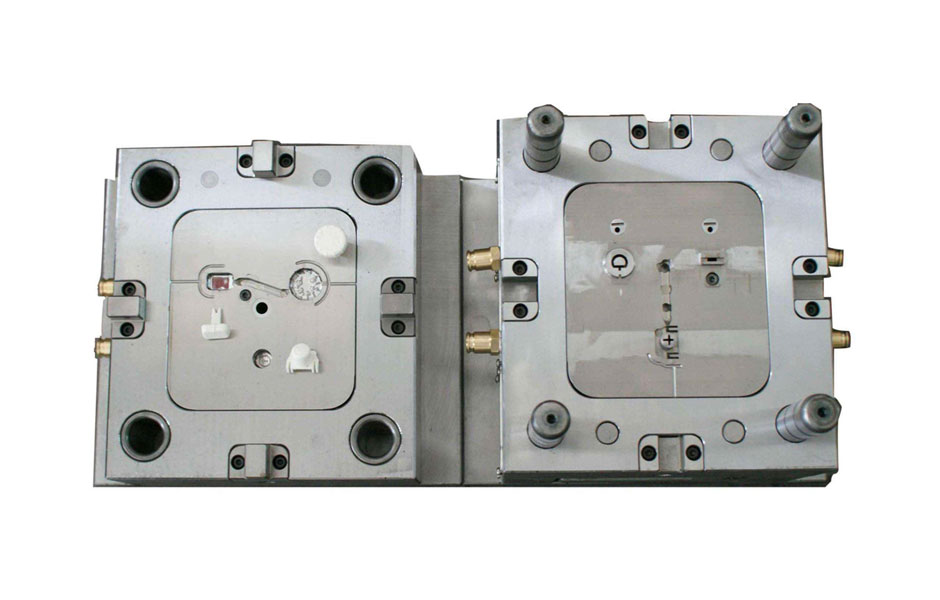

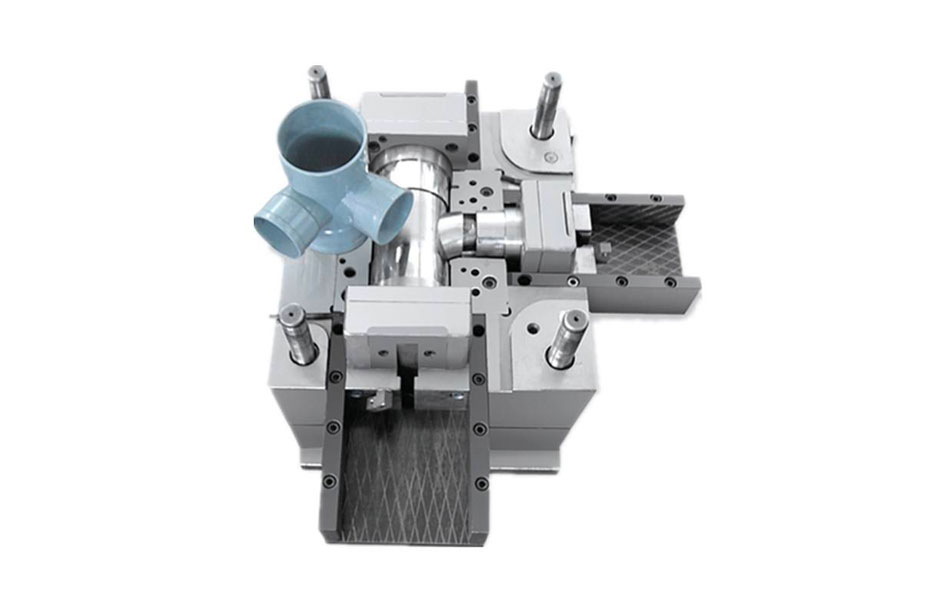

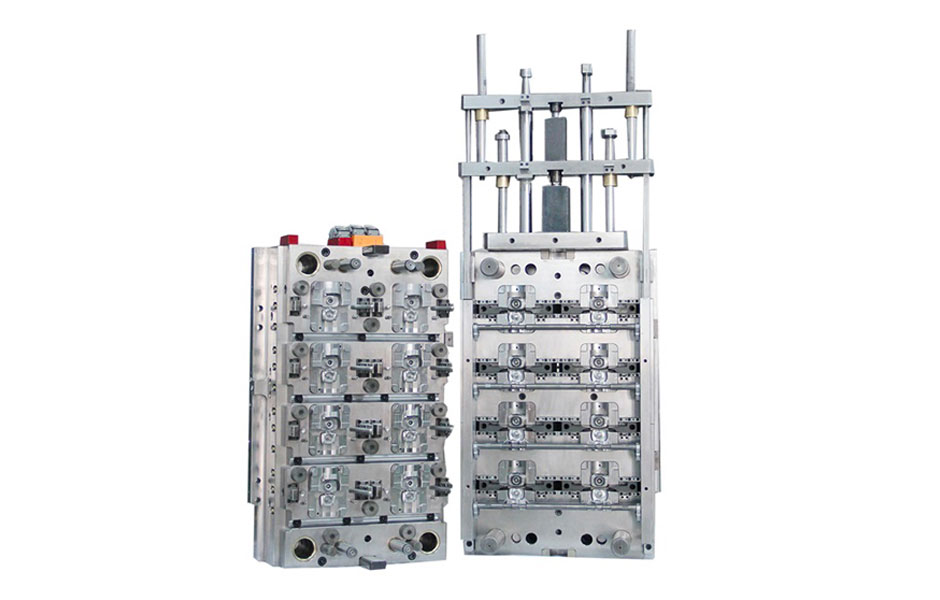

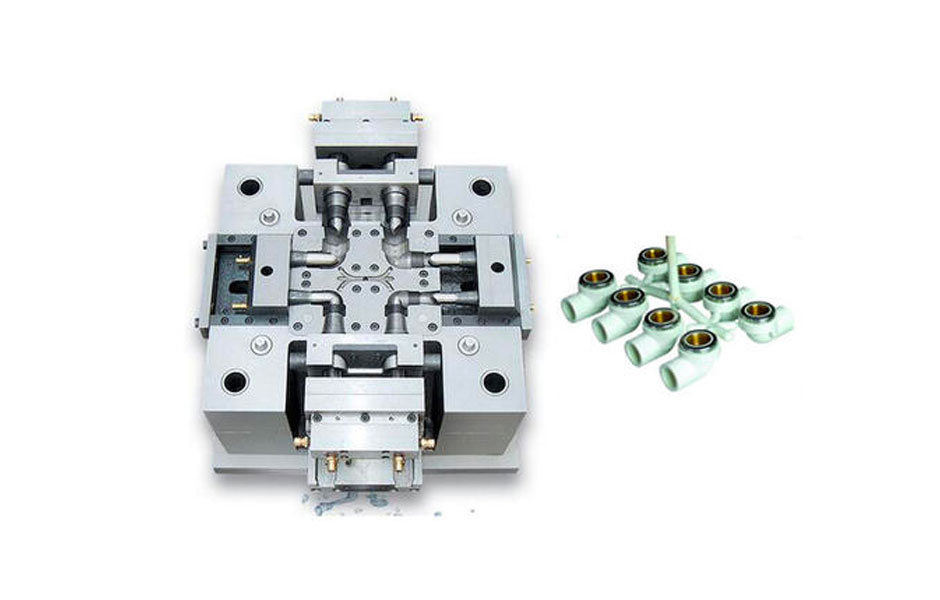

Precision Injection Mould

Precision injection is a kind of injection molding method which is difficult to meet the requirements of injection molding machine and conventional injection molding process. The concept of precision injection molding is mainly different from “conventional injection molding”. It is based on the rapid development of polymer materials, and uses precise plastic parts to replace high-precision metal parts in the instrument and electronics field.

In general, there are two indicators of precision injection molding: one is the accuracy of the equipment, and the other is the mold error. The former represents the comprehensive level of the injection molding machine because it is difficult to compare the size and thickness of the products. The weight repetition error of the general injection molding machine is about 1%. The better machine can reach 0.8%, less than 0.5% is precision machine, and less than 0.3% is ultra-precision machine. The other is the precision of the mold, which needs to be completed by high-precision mold processing equipment in addition to the experience of engineers and technicians. Therefore, first-class mold processing equipment is a necessary condition for precision injection molding.

Senses is the perfect partner for the production of high-precision and accurate injection molded plastic components. We set the bar for precision particularly high and produce innovative high-precision injection-molded parts with tolerances in the range of only 0.01 mm. With more than ten years experience, we have been manufacturing precision products for well-known customers in the automotive industry, electrical engineering and electronics. We are the perfect partner to produce high-precision plastic components.