Senses China, a leader in the injection molding industry, specializes in producing high-quality, precision-molded parts for a variety of applications, including large lawnmower parts. Our advanced technology and expertise enable us to deliver components that meet the rigorous demands of the lawn care industry and beyond.

Plastic Injection Molding for Large Lawnmower Parts Capabilities

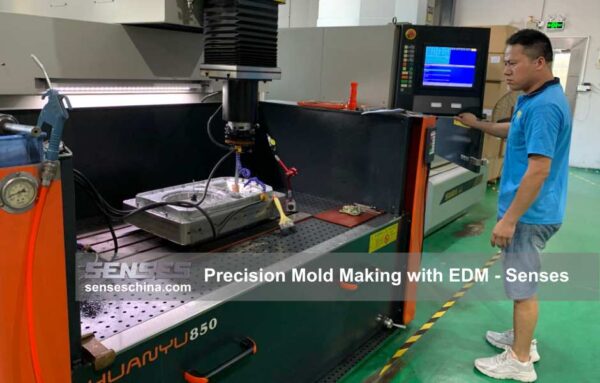

At Senses China, our advanced injection molding facilities are equipped to handle the production of large, complex parts with exceptional precision. Our advanced machinery allows us to mold heavy-duty plastic components that are essential for the performance and reliability of lawnmowers. The lawnmower parts we produce are designed to withstand harsh outdoor conditions, ensuring long-lasting durability and optimal functionality.

|

|

| learn more! |

The Injection Molding Process

The process begins with a detailed design phase, where our experienced engineers collaborate with clients to develop molds that meet their specific requirements. Using high-quality materials, we create molds that ensure the final product is both durable and precise.

During production, molten plastic is injected into these molds under high pressure. The plastic then cools and solidifies, forming the shape of the mold. This method ensures that each lawnmower part is produced with consistent quality and precision. The parts are thoroughly inspected to ensure they meet the highest standards of performance and reliability.

Customization and Flexibility

One of the key advantages of partnering with Senses China is our ability to offer customized solutions. We understand that different lawnmower models have unique requirements, and our team is adept at developing tailored components that fit specific needs. From selecting the appropriate materials to designing the perfect mold, we work closely with our clients to create parts that are optimized for their applications.

Our flexibility extends to production volumes as well. Whether you need a small batch of prototype parts or large-scale production runs, Senses China has the capability to meet your demands efficiently and cost-effectively.

Ensuring Quality Through Inspection

Quality assurance is a critical aspect of our manufacturing process at Senses China. Once the large lawnmower parts are molded, our skilled technicians meticulously inspect each part to ensure it meets our stringent quality standards. This inspection process includes checking for any defects, such as warping, surface imperfections, or dimensional inaccuracies.

learn more to contact senses china totay!

We employ both visual inspection and advanced measurement tools to verify that each part adheres to the specified tolerances. By thoroughly inspecting each part, we ensure that our clients receive components that are not only functional but also aesthetically pleasing.

learn more!

Expertise in Various Industries

While our expertise in producing lawnmower parts is well-established, Senses China’s capabilities extend to various other industries as well. Our advanced injection molding technology and skilled team enable us to produce high-quality, durable parts for automotive, electronics, medical devices, and more. This versatility makes us a valuable partner for companies in need of reliable, custom-molded components.

Commitment to Innovation

Innovation is at the core of our operations at Senses China. We continuously invest in the latest technology and training to ensure that we remain at the forefront of the injection molding industry. Our commitment to innovation allows us to provide our clients with cutting-edge solutions that enhance the performance and longevity of their products.

Contact Senses China Today!

When it comes to precision injection molding for large lawnmower parts, Senses China is a trusted partner. Our dedication to quality, innovation, and customer satisfaction sets us apart in the industry. Whether you need custom lawnmower components or parts for other industrial applications, we have the expertise and capabilities to meet your needs.

Contact us today to learn more about our injection molding services and how we can support your manufacturing requirements. Email us at info@senseschina.com.