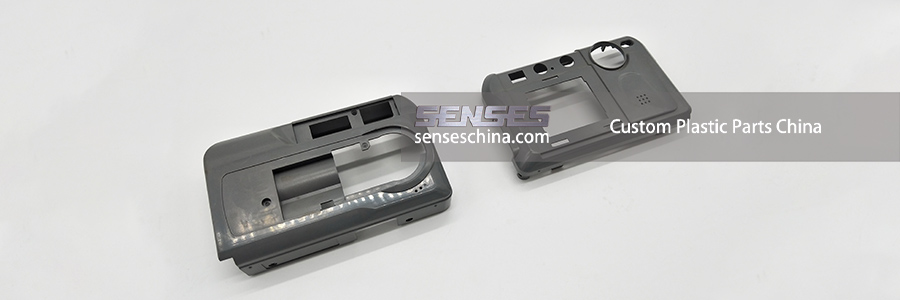

Custom Plastic Parts China

SENSES, on-demand injection molded parts. Injection molding is the most cost-effective way to make a plastic part at scale and offers consistent quality for low-to-high volume manufacturing. Molding also has the highest variety of materials, colors, and configurations when compared to CNC machining or even 3D printing. Beyond materials, injection molded parts can have custom cosmetics, polishes, or surface textures.

We inject over 20 years of experience into every project we take on, and our passionate, qualified and skilled group of professionals is really enthusiastic about plastic injection molding and your requirements.

Plastic Injection Molding Services

We can manufacture complete item or just components, regularly or just one-time purchases, and offer a customized assemblage, stamping and packing service when it is necessary.

Custom Plastic Parts China

Our team members are skilled in their individual areas of design, mold building and plastic molding, thus no matter if you’re seeking a task to have complete plastic molding production or you just require a prototype trial, we can cater to your entire demands.

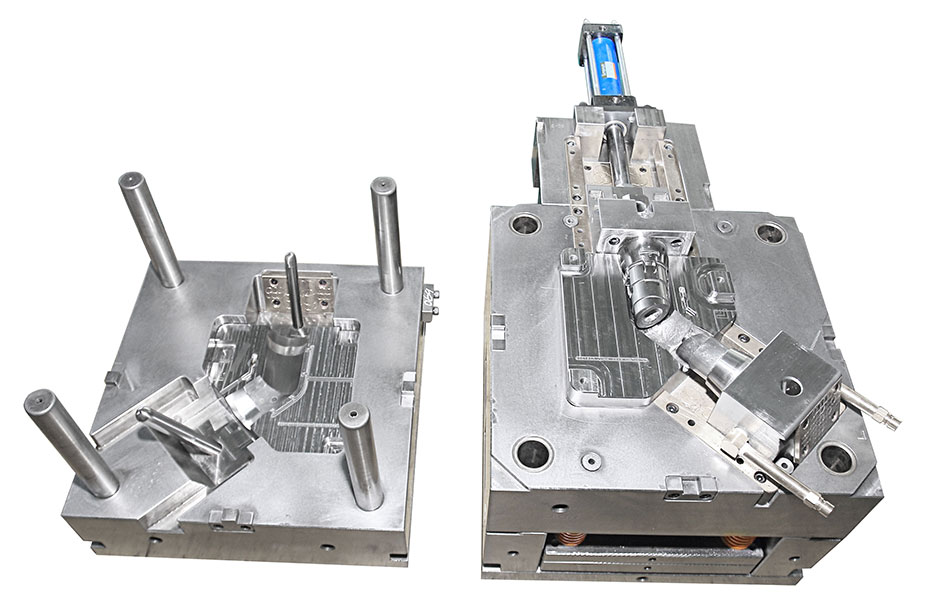

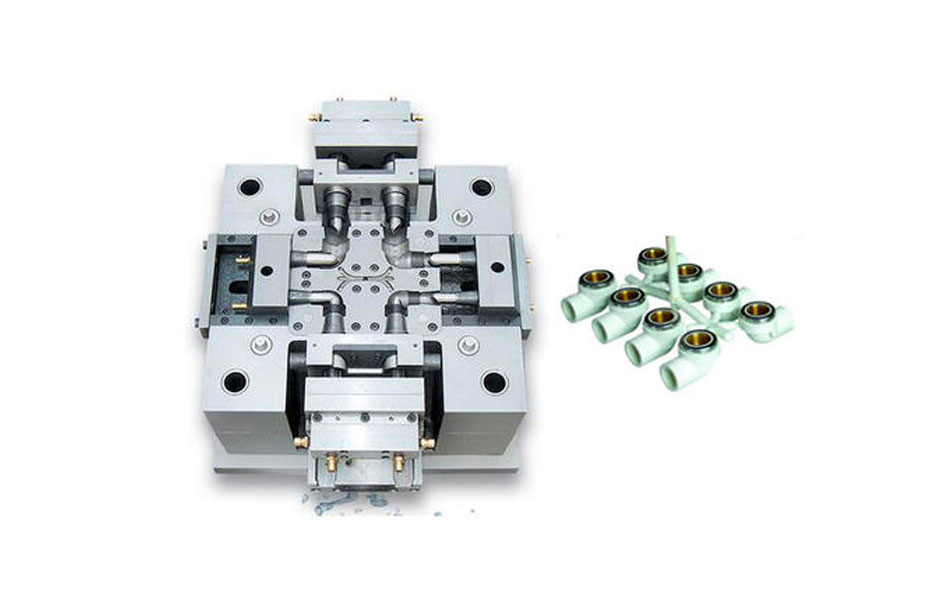

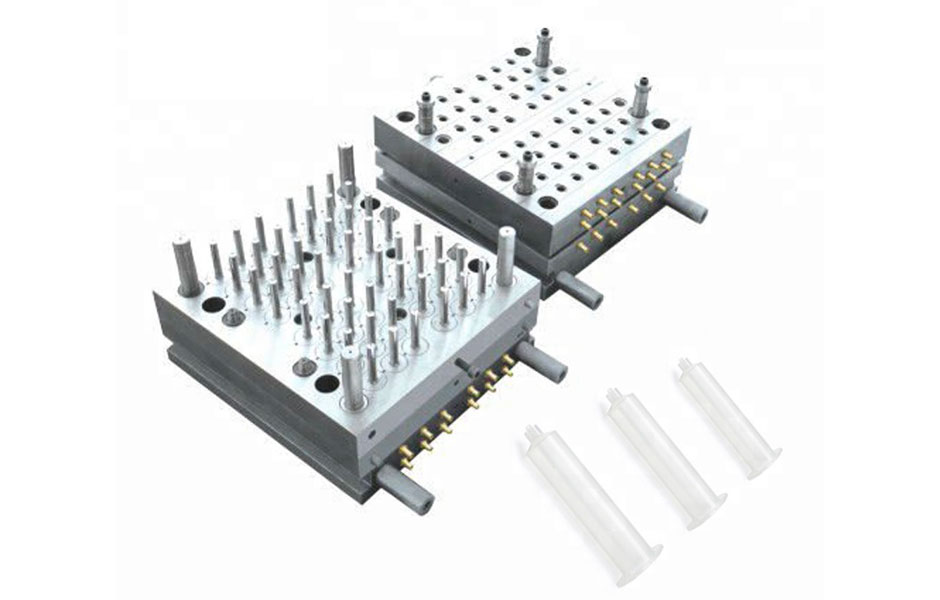

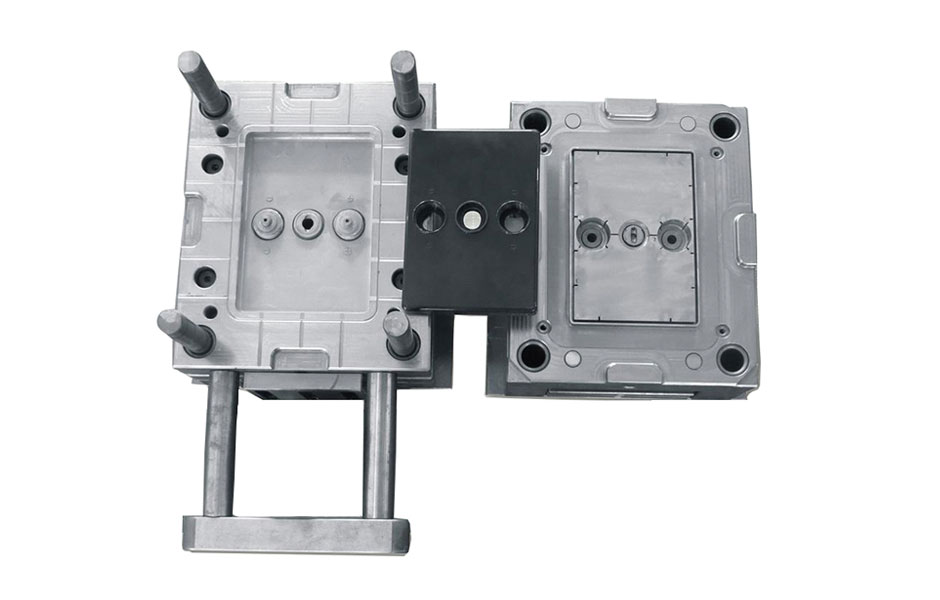

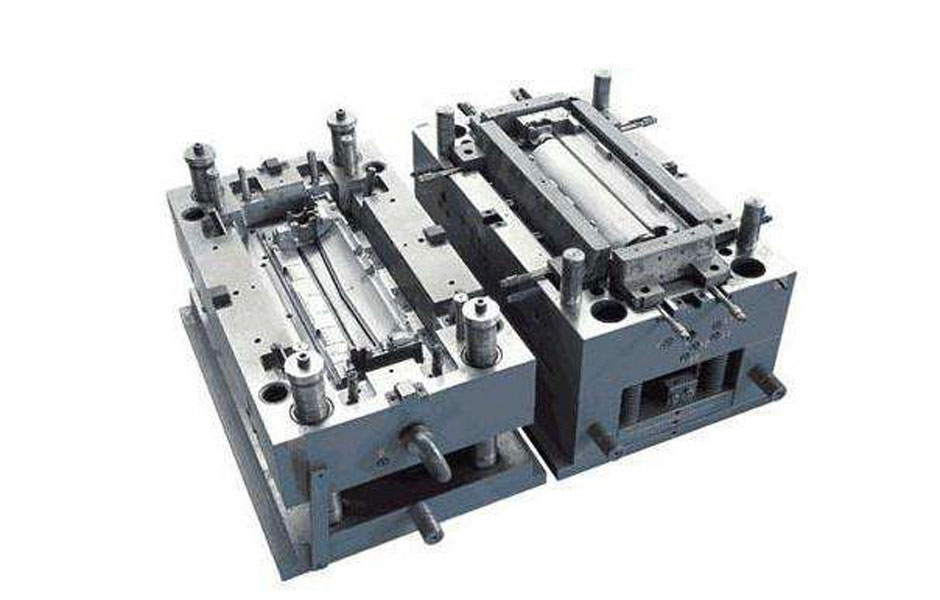

Our customers receive dedicated support for all of their validation needs and we have an experienced, expert technical team available to provide controlled sample runs with our local injection molding partner. Some of the molds we have designed and built include:

|

|

|

Automotive Injection Mould |

Appliance Injection Mould |

Precision Injection Mould |

|

|

|

Medical Device Injection Mould |

Electronic Parts Injection Mould |

Plastic Injection Moulding |

Our Advantage:

- Small details make big difference. We promise:All the parts from our company have no sharp edge. All dimensions are controlled according to your drawings. Every product will be fully inspected and carefully packed to prevent the bump and rust in transit .

- The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart.

- Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and professional inspectors.

- Each size of product must be tested one by one after completing production and provide quality report.

- The most important point, we are the entity factory, not trading company. Price is the composition of the actual product quality price. Quality can guarantee more controllable higher than trading company. The price is competitive, at least reducing the trade company’s service fee.

- We have many years of export experience,exports to the US,Europe, Japan and other countries and regions.

- Our team are more professional. We have more reasonable price and better quality controlling than trade company. And our language ability is also diversified.

Contact Us for Custom Plastic Injection Molding

If your product is still in the concept stage, you only need to present your ideas, product features and appearance requirements. Our engineers will give you the best solution, recommend the most suitable materials, and help you take the lead in the market.

We are ready and looking forward to cooperate with your next project, Contact Us Now, you will be satisfied to choose us as your partner in injection mould manufacturing& injection moulding processing.

ISO 9001:2015 and IATF16949:2016 certifications are just the beginning of our commitment to quality at SENSES. Our continuous improvement program includes identifying new technologies, improving manufacturing processes and reducing waste to deliver the highest quality injection molded components.