At the heart of every electric vehicle is its battery — the most critical component that powers the car and determines its range, safety, and efficiency.

One key part that protects and supports this vital battery is the battery enclosure. Think of it as the armor for the battery pack — shielding it from heat, moisture, vibration, and impact, while also helping manage temperature and ensuring safe operation.

Designing and manufacturing a high-quality battery enclosure isn’t simple. It requires advanced materials, precise engineering, and efficient production methods. That’s where injection molding comes in. This widely used manufacturing process allows for the creation of complex, lightweight, and durable parts at scale — making it a smart choice for many components of modern EV battery systems.

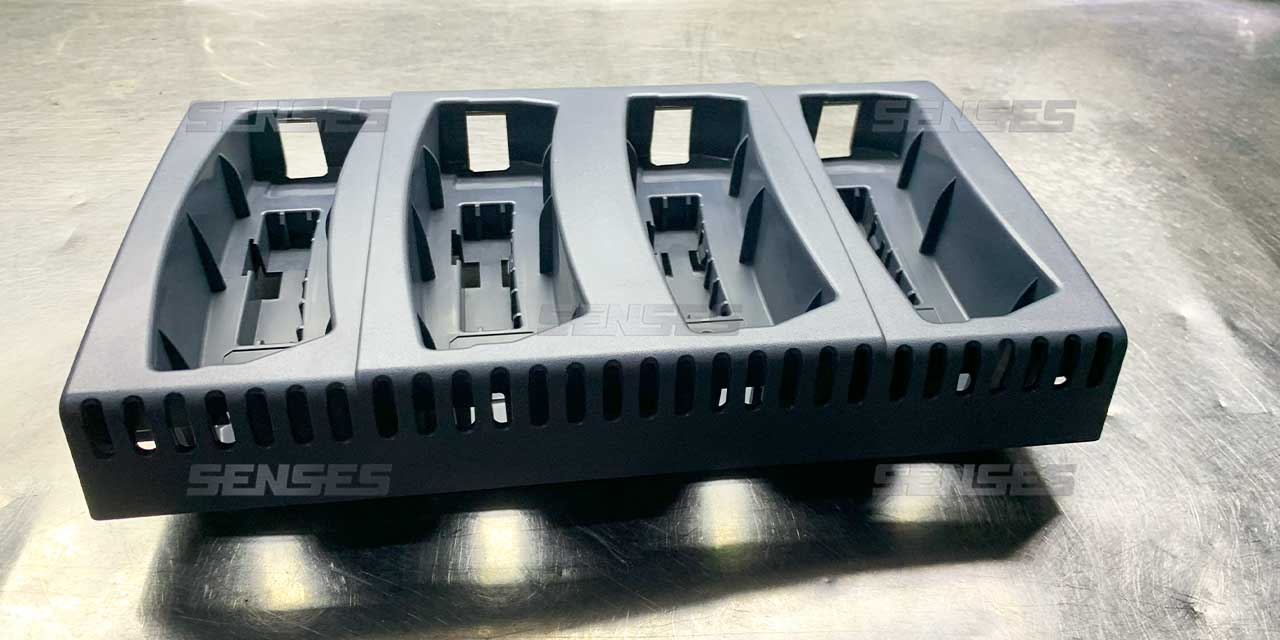

Whether you’re developing a new EV model or upgrading an existing one, choosing the right materials and manufacturing partner can make all the difference. At Senses, we specialize in precision injection molding solutions tailored for the evolving needs of the e-mobility industry. From concept to production, we help our clients bring innovative, cost-effective battery enclosure parts to life — fast and efficiently.

What is an EV Battery Enclosure?

An EV battery enclosure, also referred to as a battery housing or battery pack enclosure, is a critical structural component designed to protect the high-voltage battery pack within an electric vehicle. It serves as both a mechanical shield and a functional system integration platform, ensuring the safe and efficient operation of the battery under a wide range of environmental and operational conditions.

Typically located beneath the vehicle chassis, the battery enclosure houses not only the battery cells and modules but also essential components such as the Battery Management System (BMS), cooling systems, wiring harnesses, and safety devices. As such, it plays a pivotal role in determining the performance, durability, and safety of the entire EV powertrain.

Key Functions of an EV Battery Enclosure:

- Mechanical Protection:

The enclosure must withstand dynamic loads from road conditions, potential impacts during collisions, and static loads from the vehicle structure. It ensures that the sensitive battery components remain intact and functional throughout the vehicle’s lifespan.

- Environmental Sealing (IP Protection):

Designed to meet high ingress protection standards (often IP67 or higher), the enclosure protects internal components from water, dust, and other contaminants.

- Thermal Management:

Effective heat dissipation and temperature regulation are crucial for maintaining battery efficiency and longevity. Many enclosures integrate cooling plates or channels for liquid or air-based thermal management systems.

- Electromagnetic Interference (EMI) Shielding:

Especially important in high-voltage systems, the enclosure may be engineered to reduce electromagnetic emissions and improve signal integrity.

- Crash Safety and Electrical Isolation:

Modern enclosures incorporate features to prevent electrical shorts and ensure safe disconnection of the battery in the event of a crash or fault condition.

- Weight Optimization and Structural Integration:

With lightweight design being a key driver in EV development, enclosures are increasingly made using advanced materials and manufacturing techniques to reduce overall vehicle weight while maintaining structural rigidity.

Materials Commonly Used:

- Metals: Aluminum alloys are widely used due to their strength, thermal conductivity, and corrosion resistance.

- Plastics/Composites: Reinforced thermoplastics and fiber-reinforced polymers offer advantages in weight reduction, corrosion resistance, and cost-effective mass production via injection molding.

- Hybrid Structures: A combination of metal frames with plastic covers allows for optimized performance across different areas of the enclosure.

Manufacturing Considerations:

The choice of manufacturing process depends on material selection, part complexity, production volume, and performance requirements. Injection molding is particularly effective for producing non-load-bearing structural parts, covers, seals, connectors, and internal partitions within the battery enclosure — offering precision, repeatability, and scalability.

Benefits of Using Injection Molding for Battery Enclosures

As the electric vehicle (EV) market continues to expand, so does the demand for efficient, scalable, and cost-effective manufacturing processes. Among the various production methods available, injection molding has emerged as a preferred choice for fabricating certain components of EV battery enclosures — especially those requiring high precision, complex geometries, and large-volume production.

Injection molding involves injecting molten material — typically thermoplastic or thermoset polymers — into a mold cavity, where it cools and solidifies into the desired shape. This process offers numerous advantages when applied to EV battery enclosure manufacturing:

1. Design Flexibility and Complexity

Injection molding allows engineers to create highly intricate and customized parts that would be difficult or costly to produce using traditional metal fabrication techniques. Complex features such as integrated ribs, bosses, channels, and sealing surfaces can be molded directly into the part, reducing the need for secondary operations and assembly steps.

This level of design freedom supports the development of lightweight, space-efficient enclosures that integrate seamlessly with other vehicle systems.

2. High-Volume Production Efficiency

For automotive manufacturers aiming to scale up EV production, injection molding delivers unmatched efficiency in mass production. Once the mold is created, parts can be produced rapidly — often in cycle times of just a few seconds — making it ideal for large-scale manufacturing.

This speed-to-market advantage ensures faster time-to-revenue while maintaining consistent quality across all units produced.

3. Material Versatility

Modern injection molding supports a wide range of engineering plastics and composite materials, including:

- Glass- or carbon-fiber reinforced polymers

- High-temperature resistant resins

- Flame-retardant and conductive plastics

These materials can be selected based on specific performance requirements such as mechanical strength, thermal resistance, chemical resistance, and electrical insulation, making them suitable for different sections of the battery enclosure system.

Selecting the right EV battery enclosure suppliers is essential for ensuring performance, durability, and compliance with industry standards. Whether you’re developing a new EV model or upgrading an existing design, partnering with experienced manufacturers can make all the difference in achieving reliable results.

Injection molding has become a preferred method for producing various components of battery enclosures — especially covers, seals, internal partitions, and connectors. This process allows for high-volume production, complex designs, and material flexibility, making it ideal for modern EV applications.

At Senses, we provide precision injection molding services tailored to the needs of the e-mobility industry. Our team supports clients throughout the entire product development cycle — from mold design and material selection to mass production — ensuring quality, efficiency, and scalability for your EV battery enclosure projects.

Senses is an ISO 9001:2015 certified plastic injection molding company, offering a comprehensive array of services including mold and part design, prototyping, small-batch production, and full-scale manufacturing. We serve a diverse range of industries, encompassing automotive, medical, and consumer electronics. Our focus is on ensuring each product we deliver meets the highest standards of quality and functionality.

For personalized solutions and expert consultation, reach out to us today at info@senseschina.com.