Injection Molding Quote. Senses takes a proactive approach to plastic projects, we determine your best pathway to the marketplace based on your project’s goals and expectations. Senses is a hassle free plastic part manufacturer who can do it all under one roof We design, machine, manufacture, package, and ship all in the same building. What does this mean to customers? It means that your business is easily managed and you don’t waste time or money dealing with an inefficient process.

At Senses, Whether you need rapid manufacturing or have precision molding requirements with minimal tolerance, our team of experienced specialists can offer a cost-effective solution.

Low Volume Production Mold

Injection Molding Quote

We’re constantly refining our production process, implementing new ways to reduce inefficiencies and shorten lead times for our customers. Whether you’re looking for short run production, rapid tooling or prototyping services we can help you find the best solution and deliver it quickly and efficiently.

Quality Control

CMM Testing Center

One Stop Plastic Injection Mold & Molding Manufacturing Service

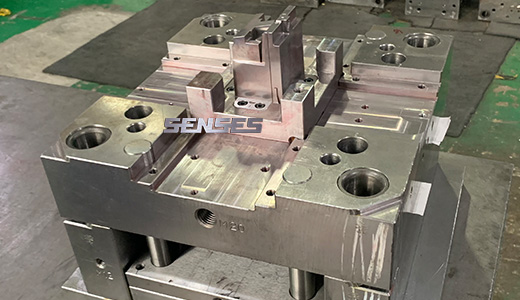

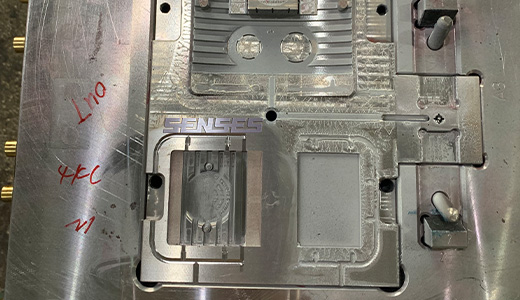

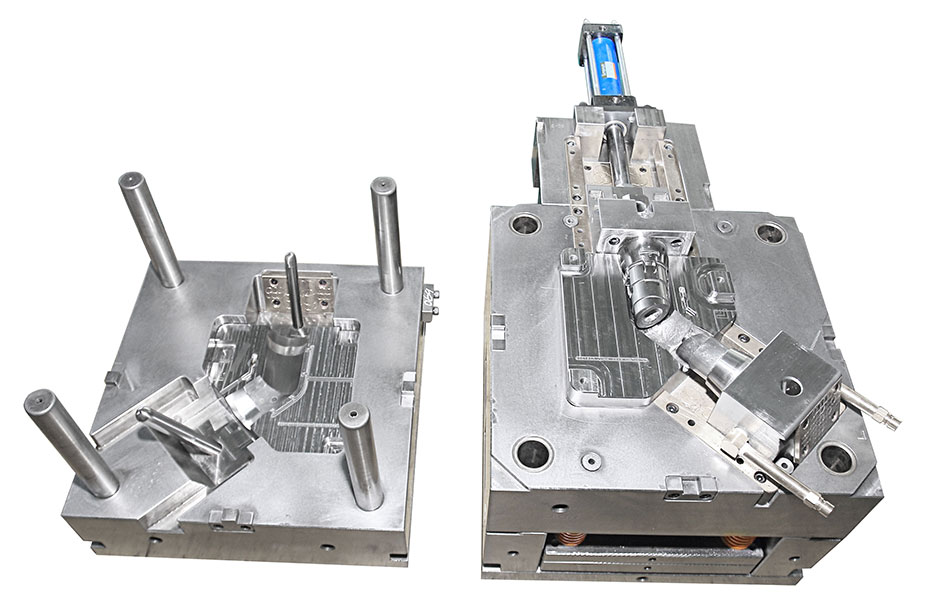

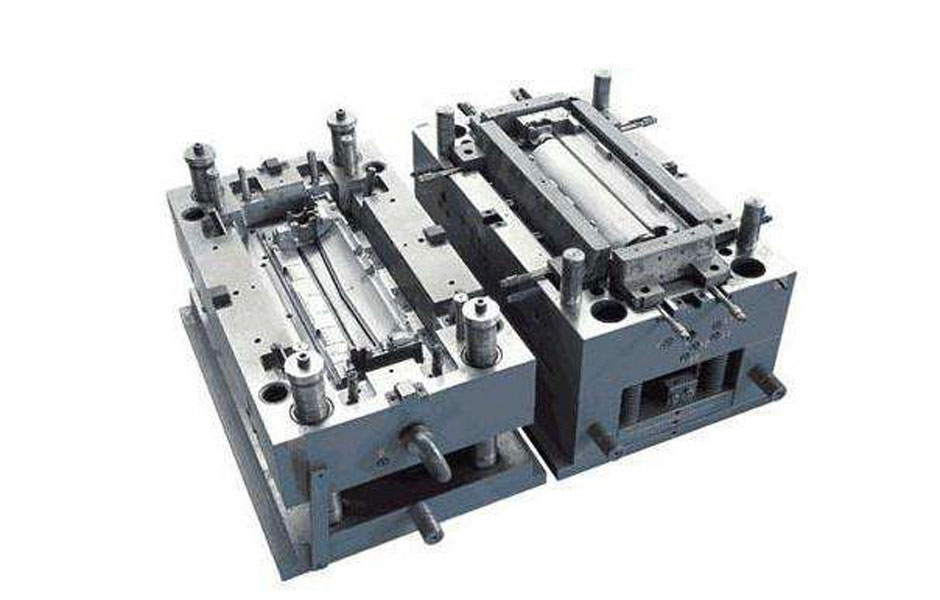

Plastic Injection Mould Manufacturer. We use state of the art technology and equipment including CAD/CAM, several high-speed CNC machining centers, wire, and conventional EDMs, milling machines, drill presses, and surface grinders.

Cross-functional teams of designers and mold makers work together to build the molds that are capable of producing production-ready parts the first time.

Low Volume Injection Molding

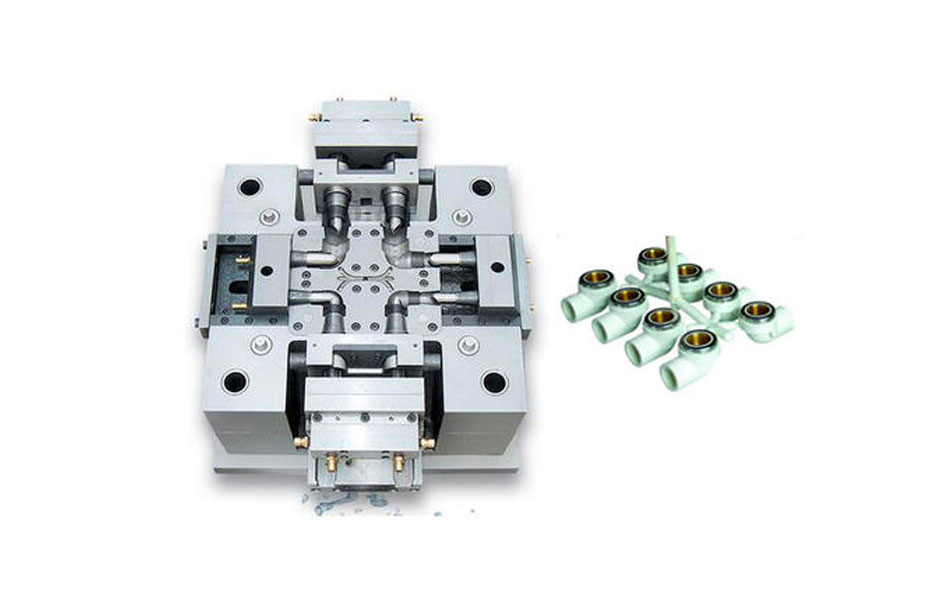

Our customers receive dedicated support for all of their validation needs and we have an experienced, expert technical team available to provide controlled sample runs with our local injection molding partner. Some of the molds we have designed and built include:

|

|

|

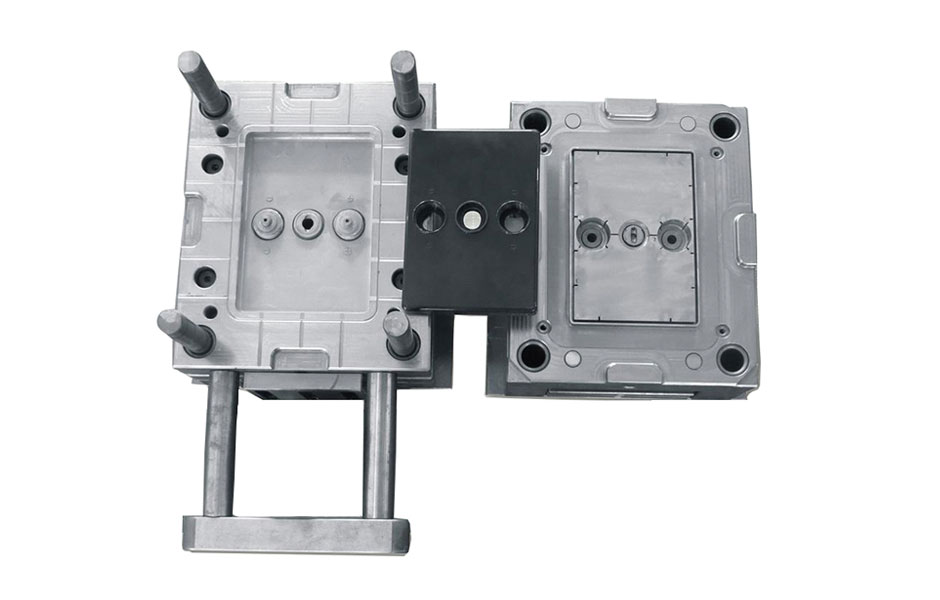

Automotive Injection Mould |

Appliance Injection Mould |

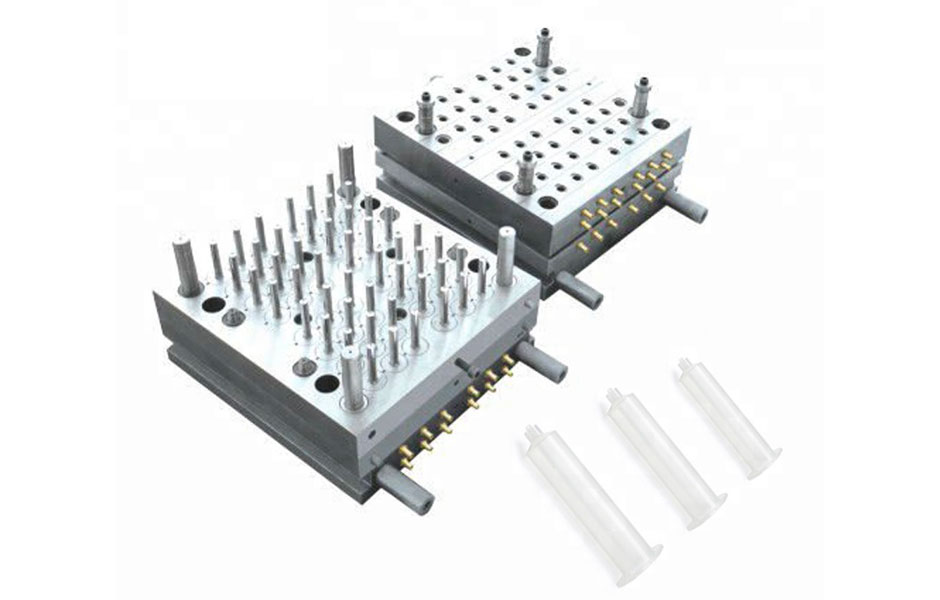

Precision Injection Mould |

|

|

|

Medical Device Injection Mould |

Electronic Parts Injection Mould |

Plastic Injection Moulding |

Contact Us for Custom Plastic Injection Molding

If your product is still in the concept stage, you only need to present your ideas, product features and appearance requirements. Our engineers will give you the best solution, recommend the most suitable materials, and help you take the lead in the market.

We are ready and looking forward to cooperate with your next project, Contact Us Now, you will be satisfied to choose us as your partner in injection mould manufacturing& injection moulding processing.

ISO 9001:2015 and IATF16949:2016 certifications are just the beginning of our commitment to quality at SENSES. Our continuous improvement program includes identifying new technologies, improving manufacturing processes and reducing waste to deliver the highest quality injection molded components.