Injection molding is a crucial manufacturing process used across various industries to produce parts in high volumes with remarkable precision. This technique involves injecting molten materials, typically plastics, into a mold where they cool and solidify into the final product. Its importance in manufacturing stems from its efficiency, scalability, and ability to produce complex geometries with excellent surface finish.

Why choose Injection Molding Service China?

China has become a global hub for injection molding services for several compelling reasons. The country offers a unique combination of technological advancement, cost efficiency, and a robust manufacturing infrastructure, making it an attractive location for companies seeking high-quality injection molding solutions.

1. Cost-Effectiveness

China’s manufacturing sector benefits from relatively low labor costs compared to many Western countries, which can significantly reduce overall production expenses. Additionally, the availability of materials and components locally reduces logistics costs, further enhancing the cost-effectiveness of manufacturing in China.

2. Advanced Manufacturing Infrastructure

Over the past few decades, China has heavily invested in developing its manufacturing infrastructure. This includes state-of-the-art factories, modern machinery, and a logistics network that ensures efficient production and distribution. Such infrastructure is particularly well-suited to the demands of injection molding, which requires precision and scalability.

3. Skilled Workforce

China has a large and skilled workforce trained in various manufacturing disciplines. This wealth of talent is crucial for injection molding, which requires technical expertise to manage the complex machinery and ensure high-quality production outcomes.

4. Scalability

The sheer scale of China’s manufacturing capacity allows for significant flexibility in production volume. Companies can easily scale their operations up or down based on market demands without significant delays or cost penalties.

5. Strong Supply Chain and Ecosystem

China’s mature and integrated supply chains offer seamless access to raw materials and auxiliary services necessary for efficient injection molding operations. This integration helps in reducing lead times and improving the reliability of supply, which is vital for maintaining continuous production cycles.

6. Government Support

The Chinese government supports the manufacturing sector through policies that encourage export, technological innovation, and import of raw materials. These policies create an environment conducive to growth and development in industries like injection molding.

7. Global Market Access

China’s strategic location and trade agreements with numerous countries provide manufacturers easy access to global markets. This is beneficial for companies looking to distribute their products internationally at competitive prices.

Overall, China offers a compelling mix of advantages for injection molding services, combining economic efficiency with advanced technological capabilities and a vast, skilled workforce. These factors make China a preferred destination for companies aiming to optimize their production processes and achieve scale in their operations.

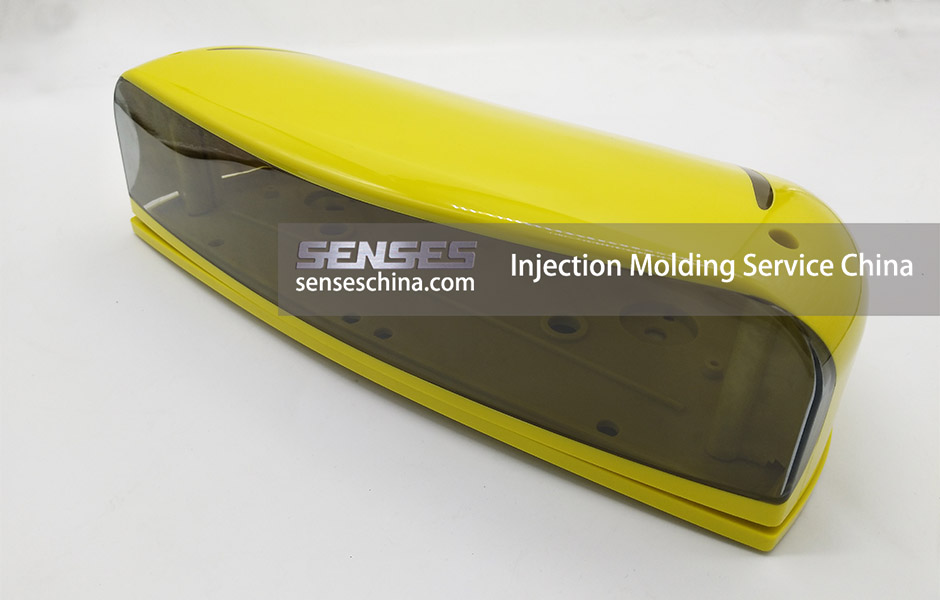

Senses’ Injection Molding: Serving Every Industry’s Needs

Senses’ injection molding services cater to a wide array of industries, each with unique demands and specifications. The versatility and precision of injection molding make it ideal for producing high-quality, detailed components essential to various sectors. Here’s how Senses supports key industries:

1. Automotive Industry

The automotive sector relies heavily on injection molding for the production of durable, precision parts such as dashboards, bumpers, and intricate components of the car’s interior and exterior. Senses provides automotive companies with solutions that meet strict industry standards for safety and durability while also enabling customization and innovation in car designs.

2. Electronics Industry

In the electronics industry, where components must be precisely manufactured to fit into compact spaces, Senses’ services are invaluable. They produce parts like casings, connectors, and mobile phone components that require high precision and excellent aesthetic qualities. Senses ensures that these parts are produced with materials that provide the necessary electrical insulation and heat resistance.

3. Healthcare Industry

In the electronics industry, where components must be precisely manufactured to fit into compact spaces, Senses’ services are invaluable. They produce parts like casings, connectors, and mobile phone components that require high precision and excellent aesthetic qualities. Senses ensures that these parts are produced with materials that provide the necessary electrical insulation and heat resistance.

4. Consumer Goods

The consumer goods industry benefits from the cost-effectiveness and scalability of injection molding for products ranging from household items to toys. Senses helps brands design and produce innovative, robust, and visually appealing products that stand out in the competitive consumer market.

5. Packaging Industry

For the packaging sector, injection molding is used to create durable, protective, and lightweight packaging solutions for food, cosmetics, and other consumer products. Senses provides packaging solutions that are not only functional but also enhance the product’s shelf appeal.

By working with these different industries, Senses uses its cutting-edge injection molding technology and know-how to meet a wide variety of technical needs. This ensures that each industry gets personalized, high-quality, and affordable manufacturing solutions.

Senses: Your Partner in Injection Molding Solutions

Senses is an ISO 9001:2015 certified plastic injection molding company, offering a comprehensive array of services including mold and part design, prototyping, small-batch production, and full-scale manufacturing. We serve a diverse range of industries, encompassing automotive, medical, and consumer electronics. Our focus is on ensuring each product we deliver meets the highest standards of quality and functionality.

For personalized solutions and expert consultation, reach out to us today at info@senseschina.com.