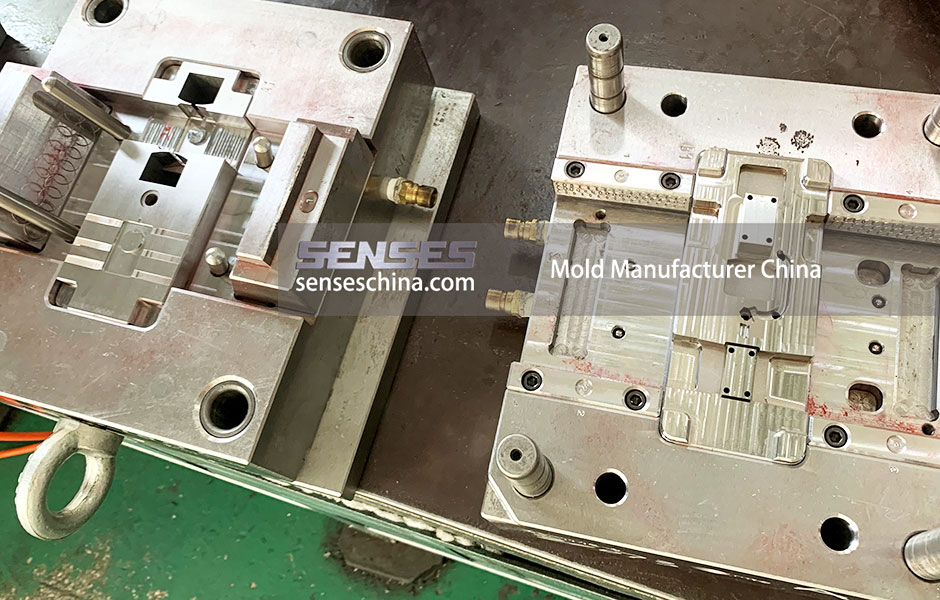

Mold Manufacturer China. Senses are Injection Mould China Company, can provide our customers from part design, prototypes, Injection Mould Making, Injection Molding Parts, and painting.

We have a rich experienced team, advanced equipment, ERP management system, which make us better on the Precision Injection Mould making with excellent service, good quality Injection Mould and after-sales insurance

|

|

|

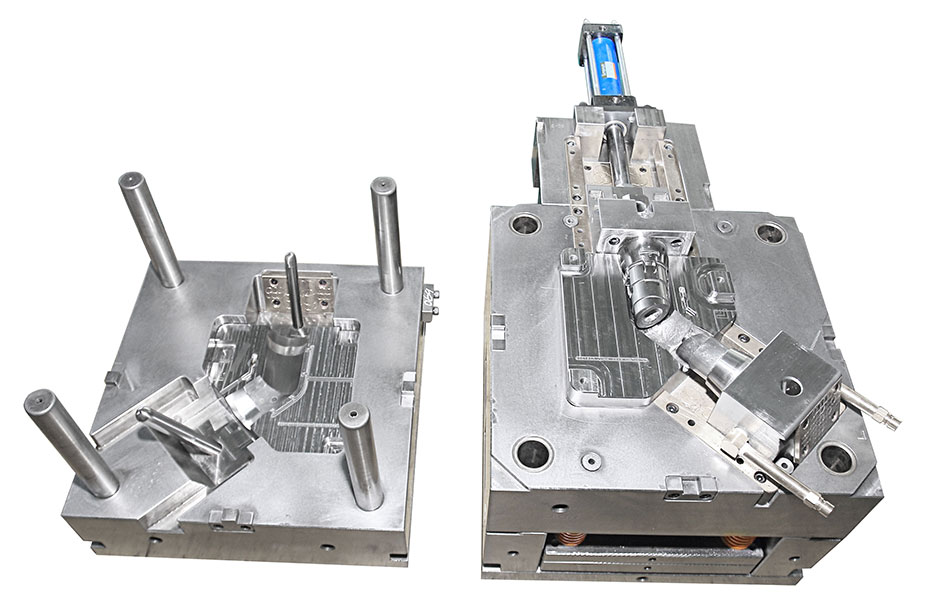

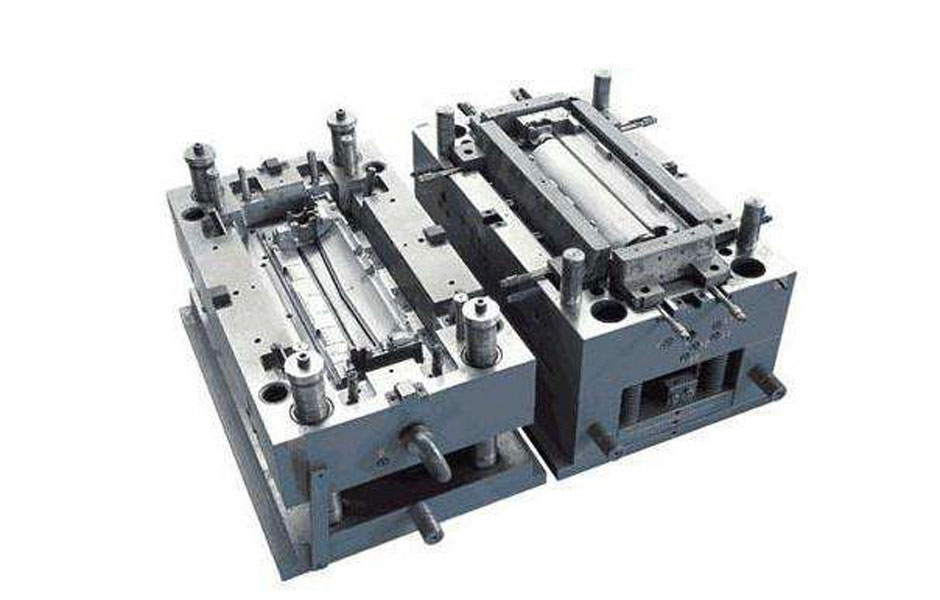

Automotive Injection Mould |

Appliance Injection Mould |

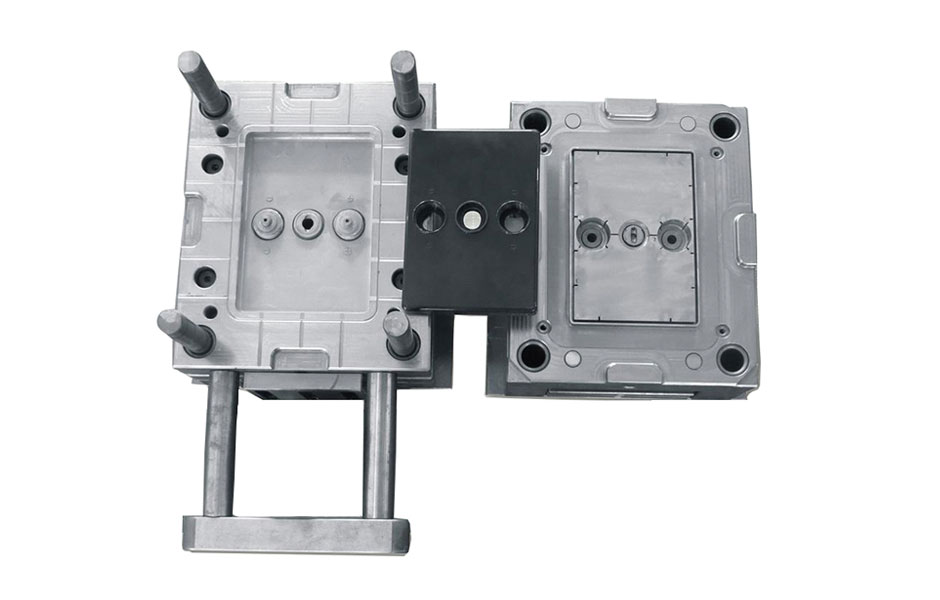

Precision Injection Mould |

|

|

|

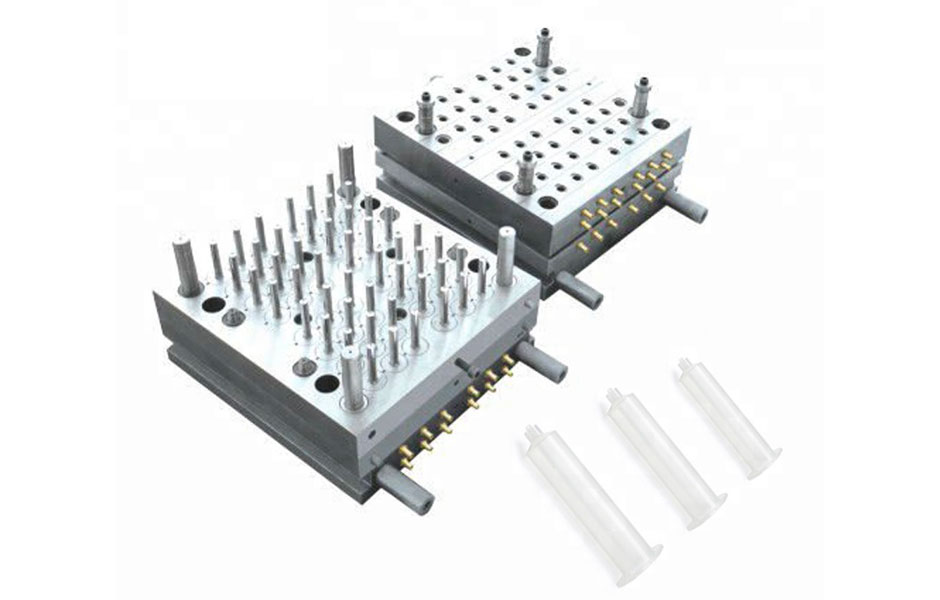

Medical Device Injection Mould |

Electronic Parts Injection Mould |

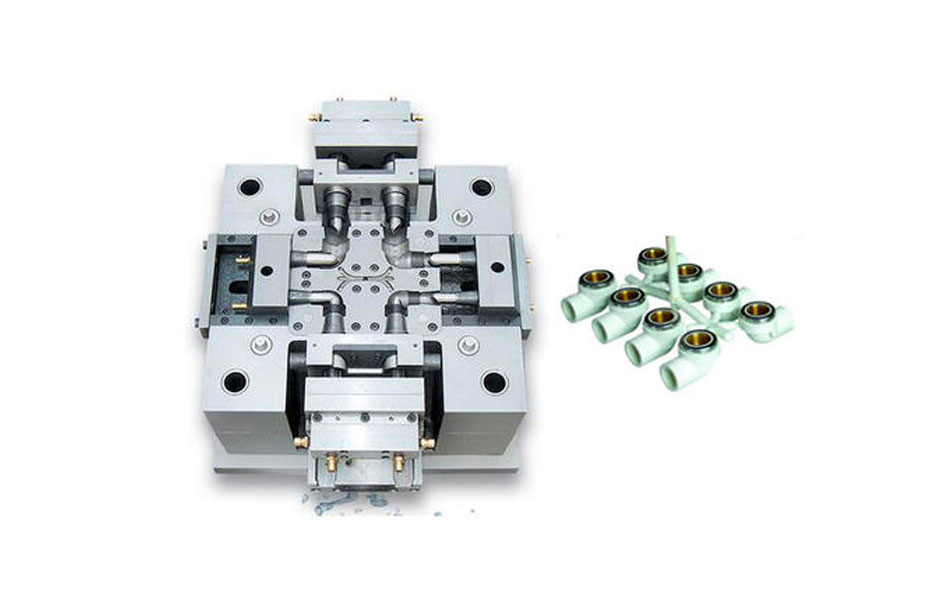

Plastic Injection Moulding |

We combine speed and flexibility to get your parts where you need them, on time, on spec, and within your budget. Our dedicated program managers are involved with the project right from the beginning to engineer effective solutions for even the most complex projects.

We believe for any low volume injection molding project to be successful, collaboration is key. This means you can rely on the experienced team of manufacturing professionals at Senses to assist you every step of the way.

One-Stop Solution

From parts & molds design to Mold manufacturer, product manufacturing, and product secondary processing.

Our flexibility allows us to hit moving targets and meet strict deadlines, while handling engineering changes efficiently with minimized impact on delivery schedule.

Advantages Of Low-Volume Manufacturing

- Create a bridge between a few prototypes and full-scale production

- Reduce cost with no minimum orders, less expensive tooling

- Provide rapid access to emerging markets

- Respond quickly to shorter product life cycles

- Allow for faster design changes

- Lower financial exposure

- Shorten production lead times

Our specialties

- Low volume plastic molding production

- Quick mold changes

- Short lead times

Mold Manufacturer Service China

Whether you’re producing micro-sized parts or something much larger, Senses has you covered. Our low volume injection molding machines range from 90 tons to 440 tons and have vertical capabilities. Production runs can vary from 100 to 100,000 parts, depending on your needs.

Contact us now

Our team of engineers and technicians are dedicated to making your custom products using the most advanced equipment and techniques including 3D printing, multi-axis CNC machining and plastic injection molding. We’re here to turn your ideas into reality quickly, accurately and at a great price. Start your project now!

When you send us your 3D CAD files, our technicians will evaluate your requirements and advise the best combination of services to meet your expectations. Contact us for a competitive quote.