Injection Moulding Services

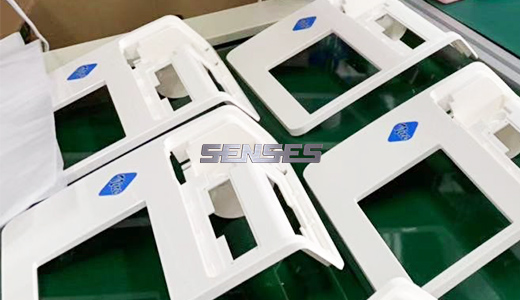

Molded Plastic Parts Manufacturers. Senses offers comprehensive services for prototyping and producing parts through a plastic injection moulding process. We have advanced machines, skills, and experience to design and manufacture injection-moulded plastic parts. Our plastic injection moulding services are suitable for a variety of industry for designing and manufacturing high-quality plastic products. We can provide you with the best plastic injection moulding quote than China. We are among the best plastic injection moulding companies who offer an amazing range of services.

Injection Moulding

Plastic Injection Molding Services

We specialize in high volume, precision plastic parts using scientific molding techniques, modern manufacturing equipment, and an ISO 9001:2015 certified quality management system. Additionally, we offer our customers a single source solution to all of their manufacturing needs, including engineering, design, tooling, production, decoration, assembly, packaging, and logistics. SENSES is your one-stop source for any plastic injection molded project.

What Is Injection Molding? Process and Advantages

Molded Plastic Parts Manufacturers. Injection molding is the manufacturing technique wherein a mold is filled with molten or melted filling material which is then cooled to produce a solid component. The material is first melted and mixed in a heated barrel, then injected under pressure into a mold where it will cool and take on the shape of the inside of the mold.

The injection molding process enables the fabrication of many parts with stringent specifications. It is necessary to have a well-designed, durable mold to achieve the level of precise repeatability necessary for large production runs. The melt flows into the mold through gates and the displaced air escapes through vents. Improper gate design will cause air to partially fill the mold, causing misshapen parts. If the vents are too small or positioned incorrectly, air bubbles may get trapped in the product or cause burn spots.

A successful injection molding operation also depends on the material used. Materials must be selected with the right mechanical properties – such as hardness, flexibility, and density – that is appropriate for the application. The cost of the material is also important for many designs, as prohibitive cost may make a product or design unfeasible.

Benefits of Injection Molding

Plastic injection molding is an extremely versatile method of producing plastic parts and has multiple advantages over other methods of plastic molding. Not only is the process simpler and more reliable than others methods, but it is also extremely efficient:

- High Efficiency- Fast Production

- Complex Part Design

- Enhanced Strength

- Flexibility- Material and Color

- Reduced Waste

- Low Labor Costs

We inject over 20 years of experience into every project we take on, and our passionate, qualified and skilled group of professionals is really enthusiastic about plastic injection molding and your requirements.

Plastic Injection Molding Services in China

Contact Us for Custom Plastic Injection Molding

If your product is still in the concept stage, you only need to present your ideas, product features and appearance requirements. Our engineers will give you the best solution, recommend the most suitable materials, and help you take the lead in the market.

We are ready and looking forward to cooperate with your next project, Contact Us Now, you will be satisfied to choose us as your partner in injection mould manufacturing& injection moulding processing.

ISO 9001:2015 and IATF16949:2016 certifications are just the beginning of our commitment to quality at Senses. Our continuous improvement program includes identifying new technologies, improving manufacturing processes and reducing waste to deliver the highest quality injection molded components.