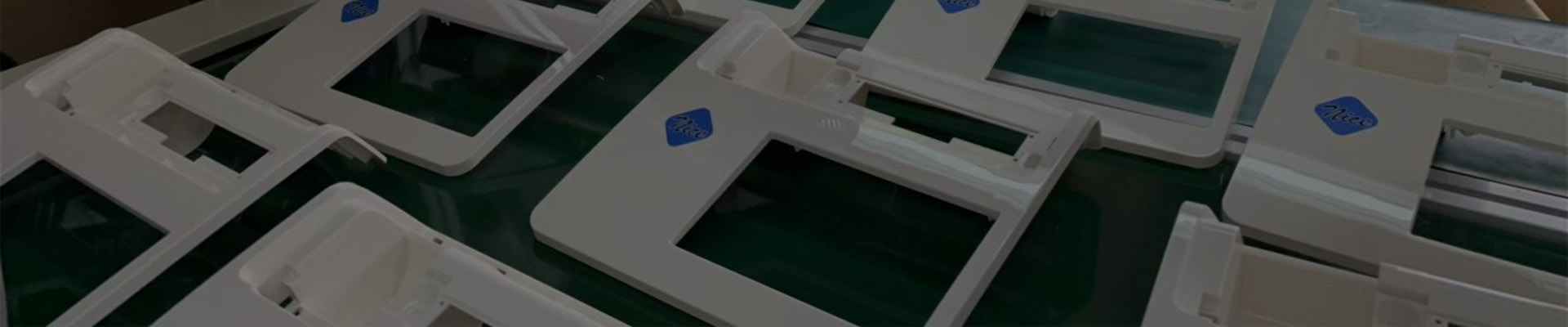

plastic molded parts

plastic molded parts. If you have a new project running in hands that need plastic molding parts, but not sure if the part structure if good enough to make plastic molds?

You are welcome to consult on our technical team, we will suggest you the best solution to assist you with better design, low cost for plastic tooling making, plastic molding manufacturing. Use the min invert cost to win the max return of your business.

If you want to have estimated price for initial market evaluation, you are welcome to send us your 3D data (in STP, IGS format), you don’t have any losses but have our competitive price for reference.

We never share your data with any other third parties, we are willing to sign the NDA document to protect your project.

We could save up to 40% Initial mold investment cost for you, if we produce the plastic molded parts for you we will never earn any piny of profits in mould making or even put 30% of tooling costing for your project (depending on the requirement of volume on your project).

If you have a technical question, you are welcome to contact our technical manager by email info@senseschina.com, who speaks fluent English and has over 15-year technical working experience, will help to solve any of your technical issues and save cost for you

If you work with us. You will be impressed and fully satisfied with our quality, price, service and fast lead time.

Our advantages for Plastic Molding Manufacturing Service

We can produce molded plastic components in a wide variety of sizes and production volumes. We have the experience to run virtually all types of products and engineered thermoplastic resins since we are a professional injection molder. We have rich experience on all type of mould structure like multiple cavities mold, overmolding, hot runner mould, small or large plastic molds, gas assist molding, double injection molding, insert molding, etc.

How Do I Select the Right Plastic Materials for Injection Molding?

People often wonder what type of plastic materials can be used for injection molding. Before selecting a material, you need to consider the performance requirements of your final product. This includes hardness, durability, heat and chemical resistance, and other factors determined by the use and operating environment.

Senses works with a wide variety of thermoplastic polymers, elastomers, and resins to create the perfect injection molded parts for your needs. Our expertise with standard specialized materials and exotic resins enables us to produce plastic injection molded parts and components to match the precise specifications of any project. The injection molding plastics we work with most often include, among many others:

- ABS provides high resistance to heat, chemicals and impact and has a tensile strength between 6,1000 and 6,500 psi. The excellent flow characteristics and high versatility of ABS makes it an ideal choice for plastic injection molding applications.

- Polycarbonate is a strong thermoplastic polymer that has high stiffness and impact strength, and excellent strength retention at high temperatures. It is easy to work with and can be used for a variety of plastic molded parts.

- PEEK is highly versatile and is commonly used to replace metal. It provides high chemical resistance at elevated temperatures, withstands autoclave sterilization, and has high hardness, stiffness and strength.

- Ultem is similar to PEEK but has lower impact strength and temperature properties. Despite this, it is one of the most dimensionally stable thermal plastics available and is highly resistant to environmental stress and cracking.

Wide Material Selection

We stock more than 100 different thermoplastic resins and accept customer-supplied materials. Our selection of injection molding materials includes:

- PA (nylon)

- PMMA (acrylic)

- Polycarbonate (PC)

- ABS

- HDPE

- POM (Acetal/Delrin)

- PEEK

- TPU

- TPE/TPV

We have been serving customers in various fields, which include Commercial/Industrial Products

Contact Us for Custom Plastic Injection Molding

Senses are the injection molding experts providing a range of injection molding solutions including overmolding, insert molding and more as well as tooling and design assistance. Request a quote to get started on your custom plastic molding project.