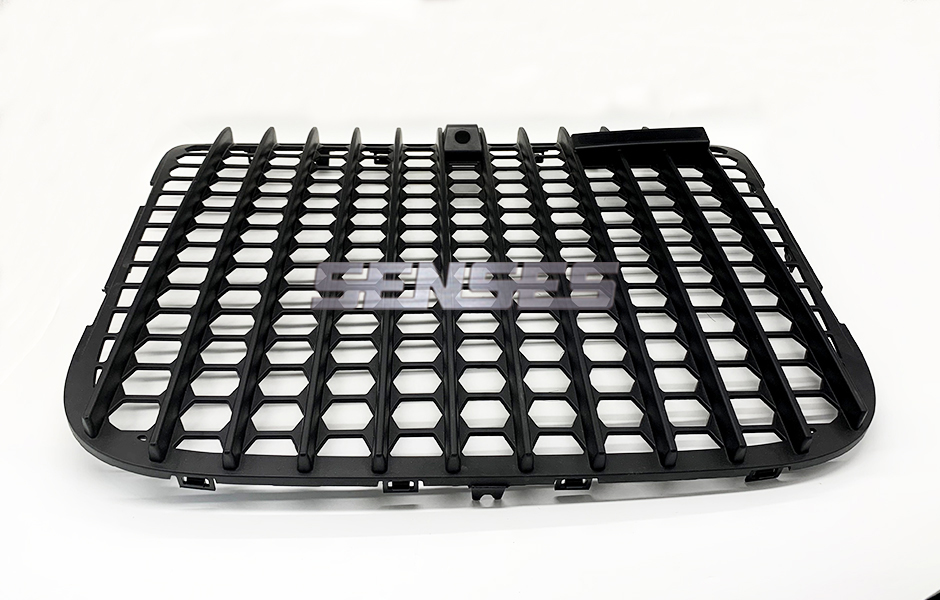

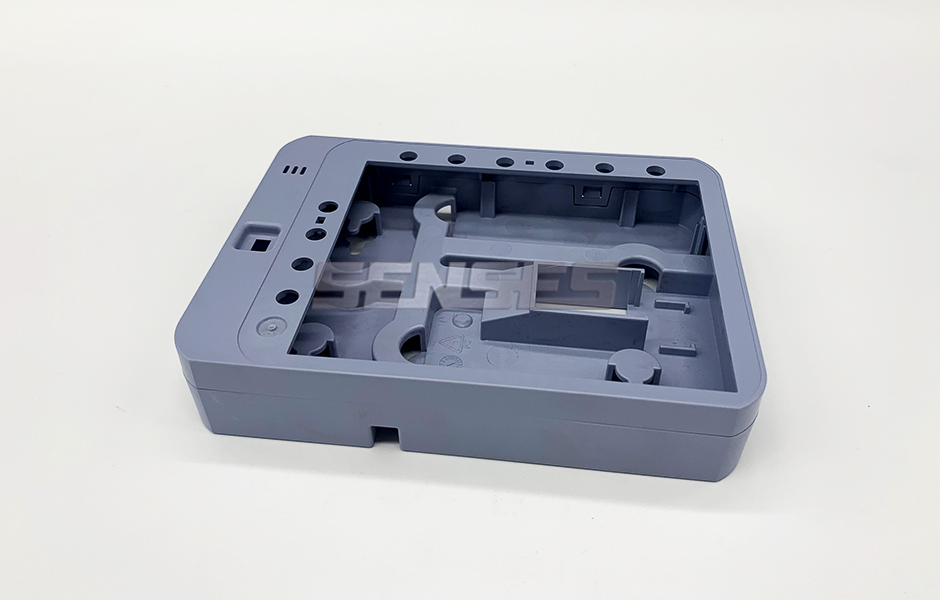

Rapid Injection Molding Companies. From plastic prototyping to production molding, Sense’s custom injection molding service is ideal for the manufacturing of competitive pricing, and high-quality molded parts in a fast lead time. Strong manufacturing facilities with powerful, precise machines ensure the same mold tool for creating consistent parts. Better yet, we provide free expert consultation on each injection molding order, including mold design advice, materials&surface finishes selection for your end-use applications, and shipping methods.

Injection molding is a popular manufacturing process for producing large quantities of plastic parts from materials called thermoplastics. It’s the process of melting plastic, injecting it into a mold then repeating the process to make thousands or even millions of the same part.

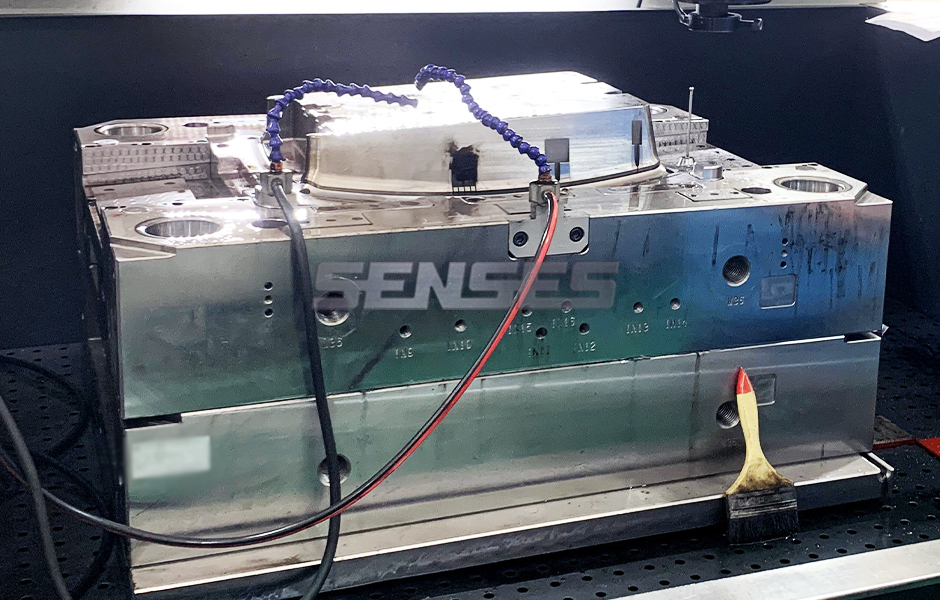

We can manufacture the injection mold per your requests with competitive prices, as we have our own mold designers and mold making factory.

There are a number of advantages to Injection molding including flexibility in design capabilities, the ability to produce high volumes of product with accuracy and consistency, fast production times, and endless color variations. However, the Initial tooling costs may be high which often make small runs less cost effective.

Injection mold design is one of most important parts of a success mold making project, we currently have 8 great mold designers with more than 10 years design experiences. For each of mold project, we will call out an internal kick-out meeting to decide the part layout, runner design, gating way, ejection method, cooling layout, etc. These would allow us to always design your mold with all of our Intelligence resources instead of just by a single mold designer.

Low-volume manufacturing

Low-volume manufacturing is the way to go if you need quantities of finished parts ranging from a few hundred up to hundreds of thousands. If you only need a few parts or prototypes, you may want to consider one of our prototyping services. At Senses, we work with you every step of the way, from initial project review and quotation to inspection and delivery.

Plastic Injection Molding Service

Rapid Injection Molding Companies

At Senses, we specialize in producing high-quality plastic injection molded parts and mold tools. We offer machining and finishing services to make tools from a variety of materials and can produce 50 to 100,000+ finished parts in a wide variety of plastics.

Contact Senses

If you’re ready to start your next project, upload your product design information for a competitive injection molding quote today. If you have any questions, please feel free to contact us at info@senseschina.com