Custom Plastic Parts Manufacturer

Custom Plastic Parts Manufacturer. We provide custom plastic injection molding for customers worldwide, in a variety of industries. We are the low-cost leader for high-quality injection molded plastics with a fast turnaround. At Senses, our focus is on providing you with the finest services in design products, rapid prototyping, tooling design & manufacturing, injection molding services, products manufacturing, assembly.

We have been serving customers in various fields, which include Commercial/Industrial Products

Plastic Injection Molding Service

Custom made products are available. Our team of engineers and technicians are dedicated to making your custom products using the most advanced equipment and techniques including 3D printing, multi-axis CNC machining and plastic injection molding. We’re here to turn your ideas into reality quickly, accurately and at a great price.

About Injection Molding

Injection molding is the most common modern method of manufacturing plastic parts. It is used to create a variety of parts with different shapes and sizes, and it is ideal for producing high volumes of the same plastic part. Injection molding is widely used for manufacturing a variety of parts, from the smallest medical device component to entire body panels of cars. A manufacturing process for producing plastic parts from both thermoplastic and thermosetting materials, injection molding can create parts with complex geometries that many other processes cannot.

Get Qualified Injection Mold Tooling China Service at Lower Cost

SENSES offers world class Rapid Injection Mold Tooling Services. We use innovative tooling techniques to manufacture high quality plastic molded parts in shorter lead-time. In the past 10 years, we helped lots of customers worldwide to launch their products fast and successfully. We aim to offer the best Injection Mold Tooling China service at lower cost and better quality.

Plastic Injection Molding Service

Plastic Injection Molding for Large Lawnmower Parts by Senses China

Senses China, a leader in the injection molding industry, specializes in producing high-quality, precision-molded parts for a variety of [...]

Injection Molding for Food-Grade Plastic Wine Glasses at Senses China

At Senses China, we specialize in the precision injection molding of food-grade plastic wine glasses, offering high-quality products that [...]

Precision Mold Assembly and Inspection for Injection Molding at Senses China

At Senses China, we understand the role that molds play in the manufacturing process, and we take great pride [...]

Custom Injection Molded White Front Panels for Electronics by Senses China

Senses China, a leader in the injection molding industry, specializing in producing precision parts perfect to the specific needs [...]

Precision Injection Molding for Custom Colored Lamp Housings at Senses China

Senses China is specializing in the precision injection molding of custom colored lamp housings and covers. Our expertise in [...]

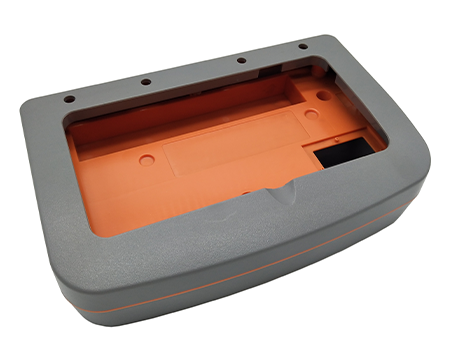

Custom Injection Molded Red Plastic Casings by Senses China

Senses China, a leader in the injection molding sector, excels in producing high-quality custom injection molded parts. Recently, our [...]

Wide Material Selection

We stock more than 100 different thermoplastic resins and accept customer-supplied materials. Our selection of injection molding materials includes:

PA (nylon)

PMMA (acrylic)

Polycarbonate (PC)

ABS

HDPE

POM (Acetal/Delrin)

PEEK

TPU

TPE/TPV

Injection Molding at SENSES

We understand every day counts when developing new products. That’s why our injection molding service is designed to deliver parts as fast as possible. Once you upload your 3D CAD file, our proprietary software will analyze the design and provide you with a quote within hours. After you place an order, you can expect parts in hand within days.