Senses China, a leader in the injection molding sector, excels in producing high-quality custom injection molded parts. Recently, our team has been working on manufacturing red plastic casings, showcasing our commitment to precision, quality, and customer satisfaction.

Advanced Injection Molding Capabilities for Red Plastic Casings

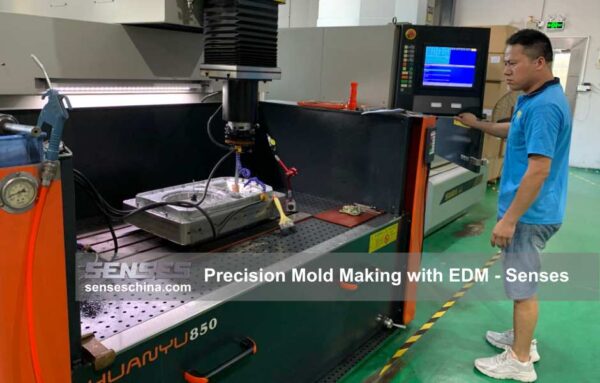

At Senses China, we use advanced injection molding technology to produce custom parts that meet exact specifications. Our facility is equipped with advanced injection molding machines that allow us to create complex shapes and designs with high precision. The red plastic casings currently being produced are a testament to our ability to handle custom projects efficiently and accurately.

The Injection Molding Process

The process begins with the design phase, where our experienced engineers work closely with clients to develop a mold that meets their specific requirements. Once the design is finalized, the mold is created using high-quality materials to ensure durability and precision.

During production, molten plastic is injected into the mold cavity under high pressure. The plastic then cools and solidifies, taking the shape of the mold. For the custom red plastic casings, the process ensures that every detail is accurately captured, resulting in a part that perfectly matches the client’s design.

Ensuring Quality Through Inspection

Quality is at the forefront of everything we do at Senses China. Once the red plastic casings are molded, our skilled technicians carefully inspect each part to ensure it meets our stringent quality standards. This inspection process includes checking for any defects such as warping, surface imperfections, or dimensional inaccuracies.

Our team uses both visual inspection and advanced measuring equipment to verify that each casing adheres to the specified tolerances. By thoroughly inspecting each part, we ensure that our clients receive products that are not only functional but also aesthetically pleasing.

The Importance of Custom Plastic Casings

Custom plastic casings are critical components in many industries, including electronics, automotive, and consumer goods. These casings protect internal components, provide structural integrity, and enhance the overall appearance of the final product. The red plastic casings produced by Senses China are designed to meet the rigorous demands of these applications, offering both durability and precision.

Benefits of Choosing Senses China

1. Expertise and Experience: With years of experience in the injection molding industry, Senses China has the expertise to handle complex custom projects. Our team of engineers and technicians is dedicated to delivering high-quality products that meet our clients’ exact specifications.

2. Advanced Technology: Our investment in advanced injection molding technology allows us to produce parts with high precision and efficiency. This technology enables us to create complex shapes and designs that would be challenging with conventional methods.

3. Commitment to Quality: Quality is a core value at Senses China. From the initial design phase to the final inspection, we implement rigorous quality control measures to ensure that every part we produce meets the highest standards.

4. Customer-Focused Approach: We work closely with our clients to understand their unique needs and provide tailored solutions that meet their requirements. Our customer-focused approach ensures that we deliver products that exceed expectations.

Partner with Senses China

When it comes to custom injection molded plastic casings, Senses China is a trusted partner. Our commitment to quality, precision, and customer satisfaction sets us apart in the industry. Whether you need a few specialized parts or large-scale production, we have the capabilities to meet your needs.

Contact us today to learn more about our custom injection molding services and how we can support your manufacturing requirements. Email us at info@senseschina.com.