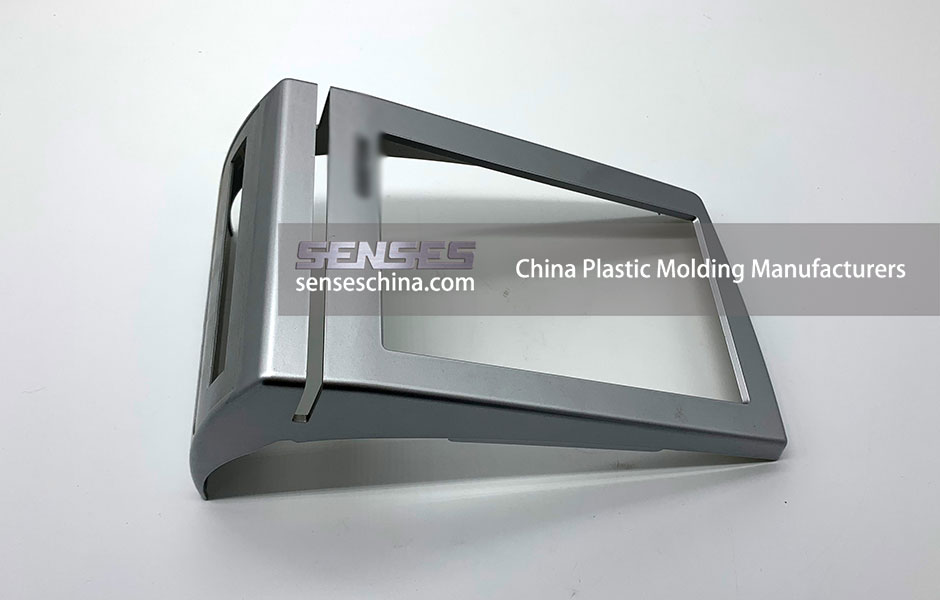

China Plastic Molding Manufacturers. At Senses, our team is committed to creating and maintaining a strong customer relationship based on reliability, service and a product that is truly second to none. Our customers range from small startups to large multinational corporations, demonstrating our high level of versatility. We welcome the opportunity to solve your most challenging plastic injection molding production requirements.

Plastic Injection Molding Services

Whether you’re in the initial stages of development or have your finished design intact, Senses is ready to provide the assistance you need. From concept development through tool manufacture, parts production, decorating, assembly and packaging of your finished product, we have the resources to produce any type of design you need.

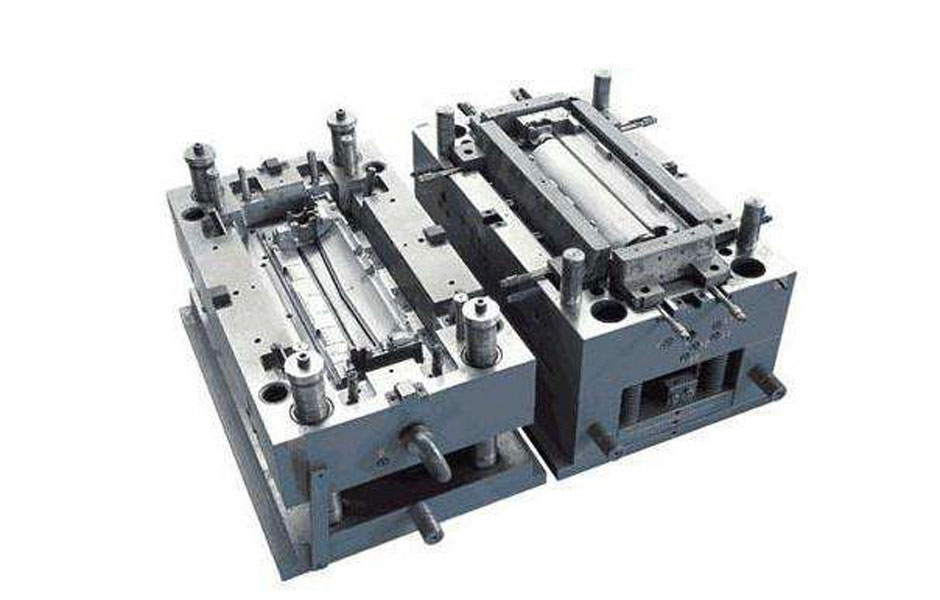

Plastic Injection Mold Making

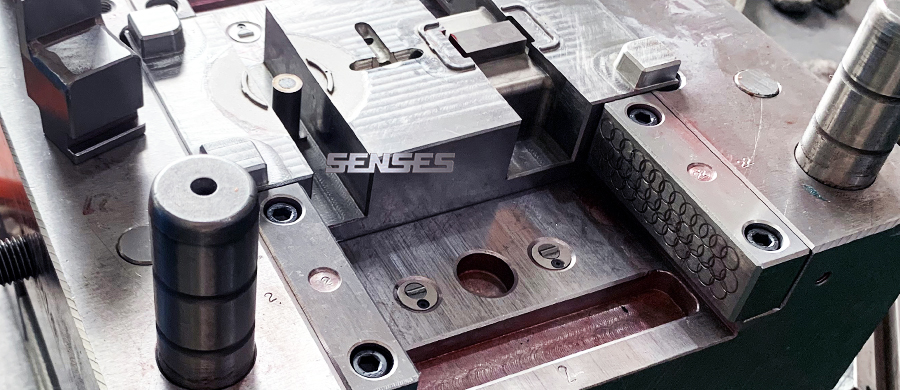

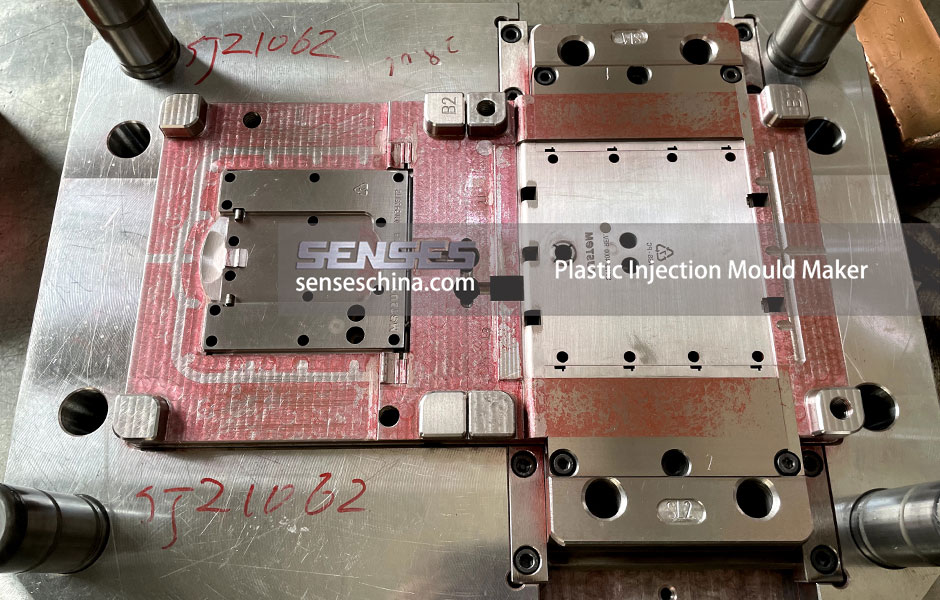

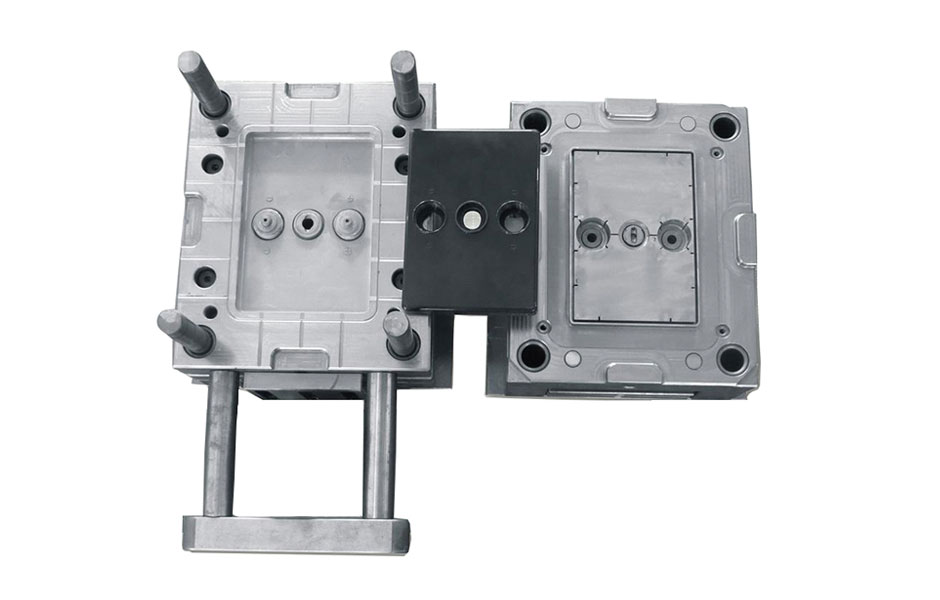

Plastic injection molds are typically constructed from hardened or pre-hardened steel, aluminum, and/or beryllium-copper alloy. Steel molds cost more but are often preferred because of their high durability. Hardened steel molds are heat-treated after machining, and they are by far superior in terms of wear resistance and lifespan.

Many steel molds are designed to process well over a million parts during their lifetime. For lower volumes, pre-hardened steel molds provide a less wear-resistant and less expensive option.

Aluminum molds, on the other hand, can cost substantially less, but they typically are ill-suited for high-volume production or parts with narrow dimensional tolerances. Nevertheless, aluminum molds can economically produce tens of thousands to hundreds of thousands of parts, when designed and built using computer numerical control (CNC) machines or Electrical Discharge Machining (EDM) processes.

Copper alloy inserts are sometimes used in areas of the mold that require fast heat removal. This can reduce cycle time and improve the aesthetic quality of the part.

Senses is a Plastic Molding Factory that specializes in full service China manufacturing solutions in plastics.

Our infrastructure in China allows for a one-stop solution for your plastic manufacturing needs from parts design, product prototyping, tooling, injection molding, and surface finishing processes to assembly, packaging and delivery.

All of our pre-sales staff members are plastics injection mold engineers who enjoy the profound experience in the field and can communicate with you without any obstacles. Contact us today for a quote!

Quality Plastic Injection Molding Services

At Senses, Whether you need rapid manufacturing or have precision molding requirements with minimal tolerance, our team of experienced specialists can offer a cost-effective solution.

Low-Volume Production Mold

China Plastic Molding Manufacturers

We’re constantly refining our production process, implementing new ways to reduce inefficiencies and shorten lead times for our customers. Whether you’re looking for short-run production, rapid tooling, or prototyping services we can help you find the best solution and deliver it quickly and efficiently.

Quality Control

CMM Testing Center

One-Stop Plastic Injection Mold & Molding Manufacturing Service

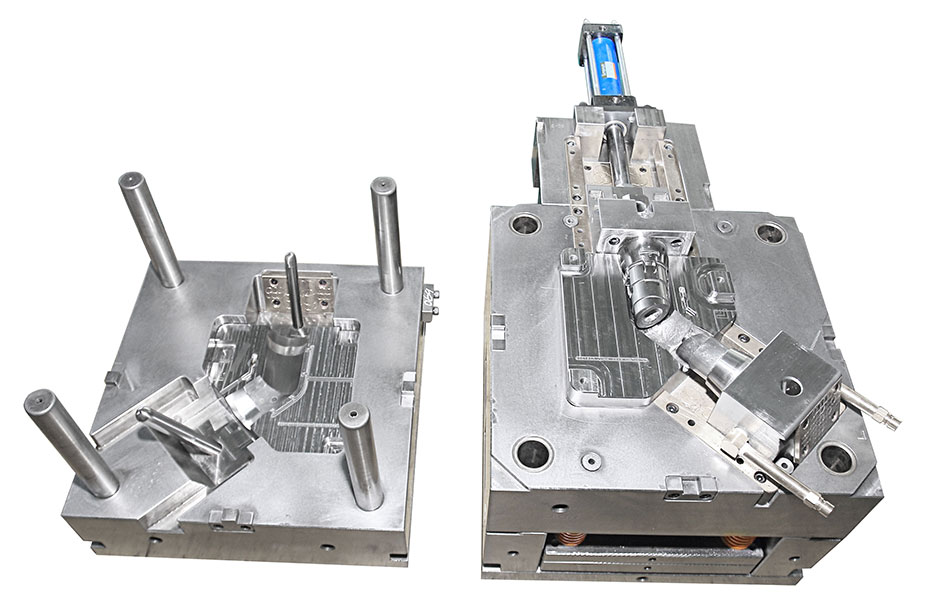

Plastic Mold Manufacturing

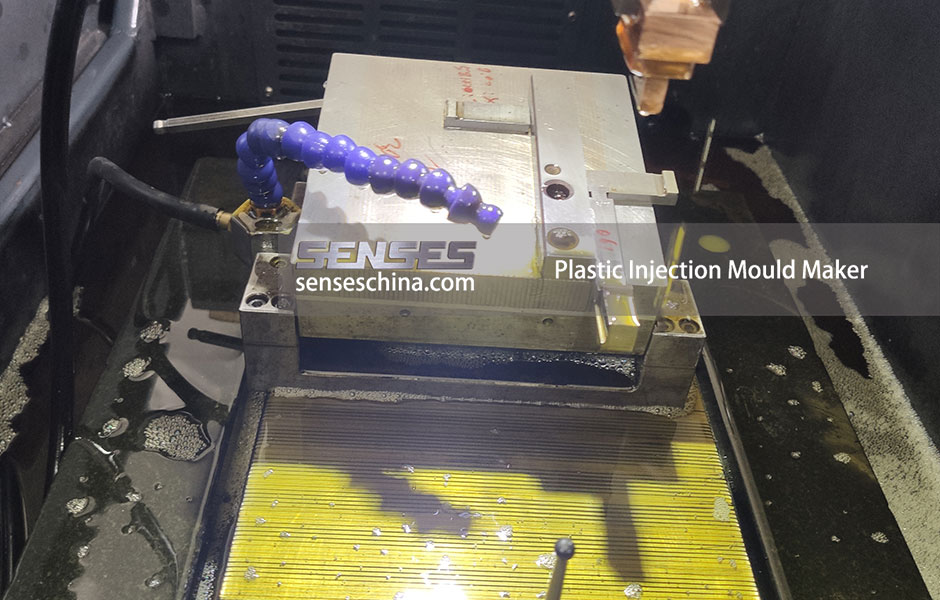

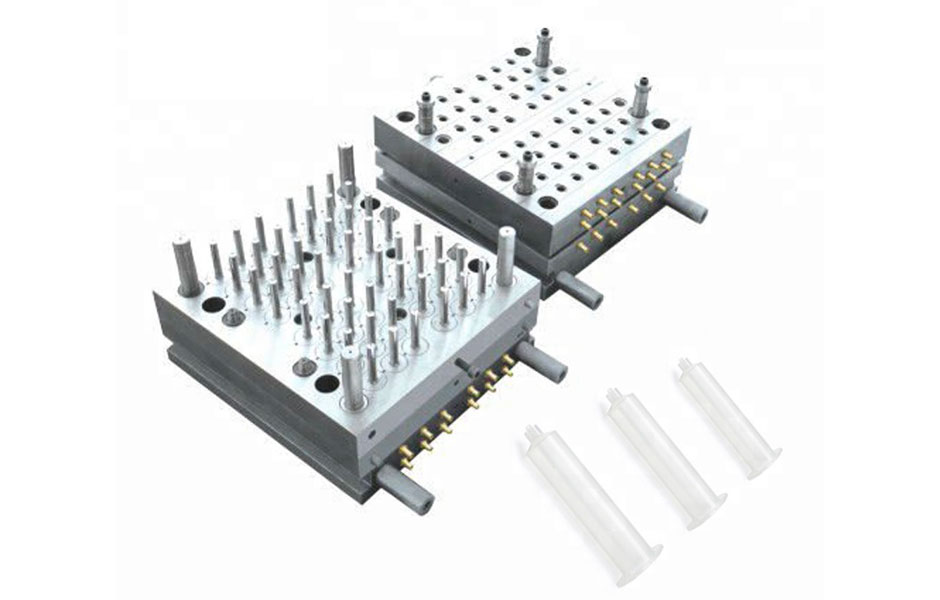

We use state-of-the-art technology and equipment including CAD/CAM, several high-speed CNC machining centers, wire, and conventional EDMs, milling machines, drill presses, and surface grinders.

Cross-functional teams of designers and mold makers work together to build the molds that are capable of producing production-ready parts the first time.

Low Volume Injection Molding

Custom Plastic Injection Molding Services

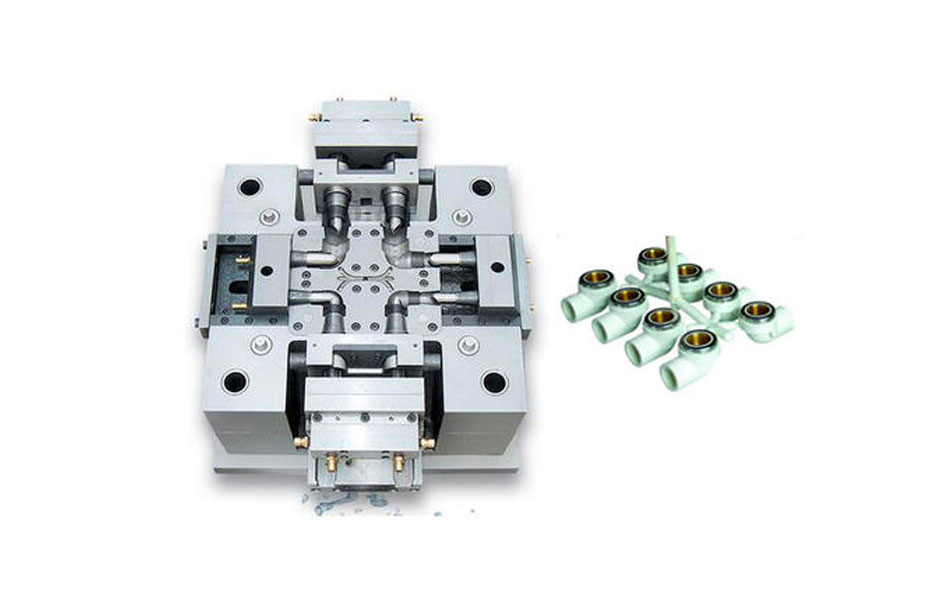

Our customers receive dedicated support for all of their validation needs and we have an experienced, expert technical team available to provide controlled sample runs with our local injection molding partner. Some of the molds we have designed and built include:

|

|

|

Automotive Injection Mould |

Appliance Injection Mould |

Precision Injection Mould |

|

|

|

Medical Device Injection Mould |

Electronic Parts Injection Mould |

Plastic Injection Moulding |

Contact Us for Custom Plastic Injection Molding

If your product is still in the concept stage, you only need to present your ideas, product features and appearance requirements. Our engineers will give you the best solution, recommend the most suitable materials, and help you take the lead in the market.

We are ready and looking forward to cooperate with your next project, Contact Us Now, you will be satisfied to choose us as your partner in injection mould manufacturing& injection moulding processing.

ISO 9001:2015 and IATF16949:2016 certifications are just the beginning of our commitment to quality at SENSES. Our continuous improvement program includes identifying new technologies, improving manufacturing processes and reducing waste to deliver the highest quality injection molded components.