We provide custom injection molding for customers worldwide, in a variety of industries. We are the low-cost leader for high-quality injection molded plastics with a fast turnaround.

Advantages of Plastic Injection Molding:

1. Complex Part structure available

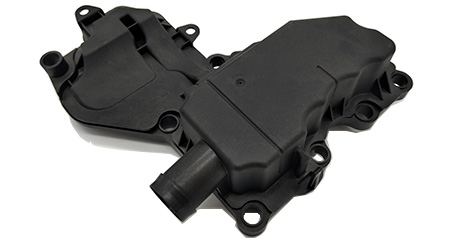

Compared to other manufacturing process, plastic injection molding has big advantage on complex part geometry, it means you can design a plastic part as complex possible to realize product function while not increasing too much cost. This is what any other molding process or machining process can never achieve it.

2. High Efficiency, Easy Mass Production

As we know, there is a mold tool on injection machining while injection molding process. It takes seconds or a minute to get a plastic parts. The manufacturing cycle is quite short compared to CNC machining, die casting, or other molding process. Therefore it’s easy when you are going to produce it in large volume.

3. Flexible Color and Material

When a plastic injection molding production, it is very flexible to allow customer to have different product color and different material manufactured. it will quickly obtain different style of molded products.

4. Easy for Engineering Modification

As we know, any of product development might change a lot so as to optimize a better products. If you design a plastic parts, you can make engineering change easily and conveniently by mold modification or injection molding parameter adjustment.

5. Cost-effective

Up to now, plastic injection molding is the most cost-effective way to obtain products. Because the cost of resin and manufacturing process is much lower than metal machining or other molding process. (about 5~10 times cheaper). This is why most of product components are consisted of plastic parts.

we provide a total concept solution from design and tooling to production, fulfillment, and packaging. The combined effort of our designers and toolmakers results in molds that ensure quality, precision tolerances, and optimized cycle times. We have the capacity to mold parts with complex geometries and variations in wall thickness.

Our Advantage:

1. Small details make big difference. We promise:All the parts from our company have no sharp edge. All dimensions are controlled according to your drawings. Every product will be fully inspected and carefully packed to prevent the bump and rust in transit .

2. The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart.

3. Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and professional inspectors.

4. Each size of product must be tested one by one after completing production and provide quality report.

5. The most important point, we are the entity factory, not trading company. Price is the composition of the actual product quality price. Quality can guarantee more controllable higher than trading company. The price is competitive, at least reducing the trade company’s service fee.

6.We have many years of export experience,exports to the US,Europe, Japan and other countries and regions.

7.Our team are more professional. We have more reasonable price and better quality controlling than trade company. And our language ability is also diversified.

We have been serving customers in various fields, which include Commercial/Industrial Products

Custom Plastic Moulding Company

If your product is still in the concept stage, you only need to present your ideas, product features and appearance requirements. Our engineers will give you the best solution, recommend the most suitable materials, and help you take the lead in the market.

We are ready and looking forward to cooperate with your next project, Contact Us Now, you will be satisfied to choose us as your partner in injection mould manufacturing& injection moulding processing.

ISO 9001:2015 and IATF16949:2016 certifications are just the beginning of our commitment to quality at Senses. Our continuous improvement program includes identifying new technologies, improving manufacturing processes and reducing waste to deliver the highest quality injection molded components.