Custom molded plastic parts are made possible through a process known as injection molding. Injection molding is a manufacturing process that involves injecting material like metal, glass, elastomers and thermosetting plastics into a mold in order to produce certain parts. Here’s a simple, step-by-step process of how it works:

- The material for the part is fed into a heated barrel.

- In the barrel it is mixed and forced into a mold cavity.

- It then cools and hardens to the shape of the cavity.

Designing a custom mold for plastic parts requires intricate planning and attention to details. Recruiting the help of industrial designers and engineers is crucial to the quality of the resulting plastic part. At SENSES, we have a professional mechanical engineer on staff to handle our design and creation needs. We are custom plastic parts manufacturers who know how to mold plastic parts using cost-effective prototype tooling.

We Work with You from Design to Production

SENSES provides a turnkey solution to custom plastic molding projects. We are capable of meeting all your needs, from the beginning concept to the final production. When you work with us, you’ll have the ability to tell us what you want, even if you start out with just a basic “napkin sketch.” More benefits you can count on when you partner with us for plastic part manufacturing.

Not only can you count on our staff to do a high-quality job based on their years of experience and knowledge, but you can also count on our equipment to get the job done right. We have sprue pickers, conveyors, material loaders, grinders, material mixers and material dryers, and that’s just the beginning. We have the expertise and equipment to help you in any way you need it.

We have been serving customers in various fields, which include Commercial/Industrial Products

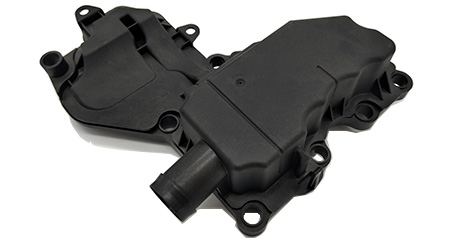

Custom Molded Plastic Parts

If your product is still in the concept stage, you only need to present your ideas, product features and appearance requirements. Our engineers will give you the best solution, recommend the most suitable materials, and help you take the lead in the market.

We are ready and looking forward to cooperate with your next project, Contact Us Now, you will be satisfied to choose us as your partner in injection mould manufacturing& injection moulding processing.

ISO 9001:2015 and IATF16949:2016 certifications are just the beginning of our commitment to quality at Senses. Our continuous improvement program includes identifying new technologies, improving manufacturing processes and reducing waste to deliver the highest quality injection molded components.