The difference between moldability and manufacturability may seem subtle, but the reality is that understanding it better can have an impact on your part development.

What is Moldability?

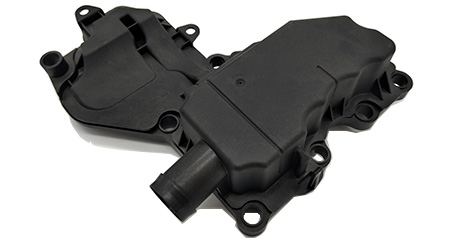

Moldability refers to how well the mold of your part will conform to being injected with molten plastic. Once your mold has been created from your design, a good injection molding process needs to account for how well plastic can fill that mold cavity. From material selection to mold complexity, there are many factors that will determine whether the part you designed is capable of accepting this process. Certain features in your part design like undercuts and threading, can be tricky to mold correctly and consistently. These can cause problems like knit lines, warp and flash.

What is Manufacturability?

Manufacturability refers to whether or not the mold itself can actually be created based on the geometry of your part. The complexity of your design can cause some real headaches for injection molding manufacturers. As a result, you will be told that your design is not manufacturable and you’ll be asked to remove features to make it manufacturable…for them. After all, how would you know if it really was or wasn’t?

our experienced sales engineers will review your file and figure out the best, most cost-effective way to manufacture it.

we provide a total concept solution from design and tooling to production, fulfillment, and packaging. The combined effort of our designers and toolmakers results in molds that ensure quality, precision tolerances, and optimized cycle times. We have the capacity to mold parts with complex geometries and variations in wall thickness.

Our Advantage:

1. Small details make big difference. We promise:All the parts from our company have no sharp edge. All dimensions are controlled according to your drawings. Every product will be fully inspected and carefully packed to prevent the bump and rust in transit .

2. The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart.

3. Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and professional inspectors.

4. Each size of product must be tested one by one after completing production and provide quality report.

5. The most important point, we are the entity factory, not trading company. Price is the composition of the actual product quality price. Quality can guarantee more controllable higher than trading company. The price is competitive, at least reducing the trade company’s service fee.

6.We have many years of export experience,exports to the US,Europe, Japan and other countries and regions.

7.Our team are more professional. We have more reasonable price and better quality controlling than trade company. And our language ability is also diversified.

We have been serving customers in various fields, which include Commercial/Industrial Products

Custom Plastic Moulding Company

If your product is still in the concept stage, you only need to present your ideas, product features and appearance requirements. Our engineers will give you the best solution, recommend the most suitable materials, and help you take the lead in the market.

We are ready and looking forward to cooperate with your next project, Contact Us Now, you will be satisfied to choose us as your partner in injection mould manufacturing& injection moulding processing.