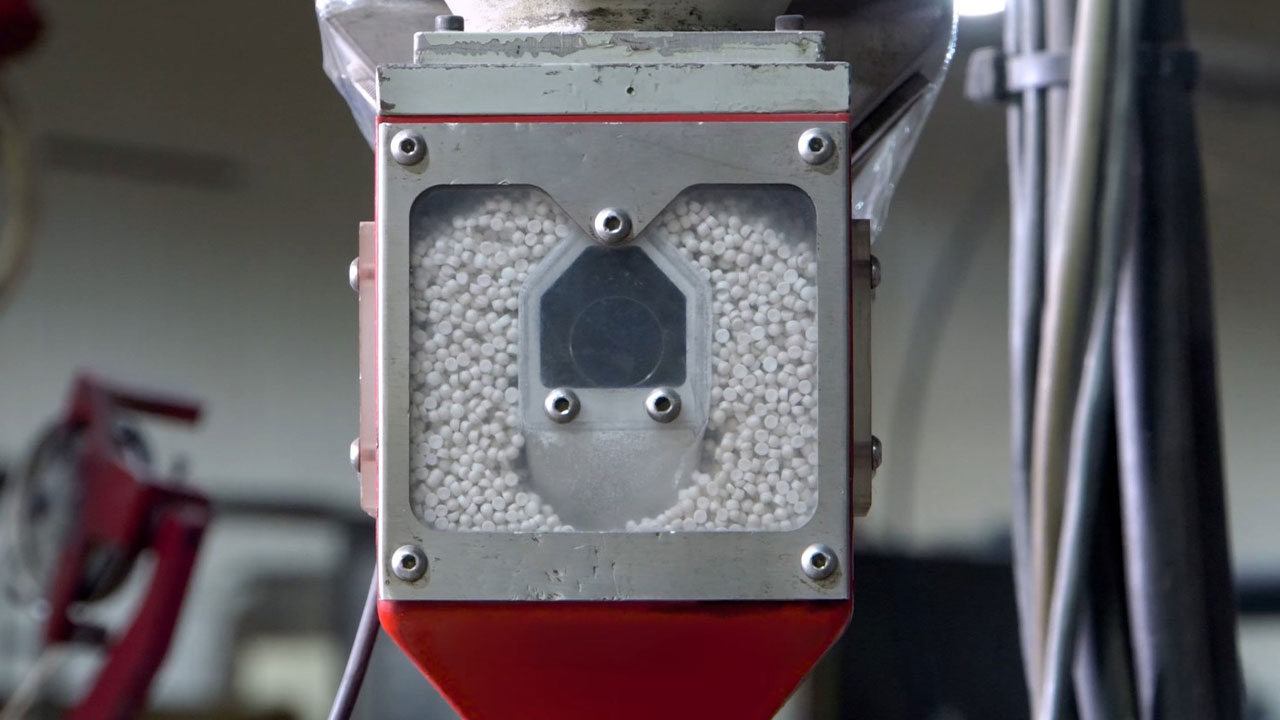

Choosing the right material for injection molding is a vital step in creating efficient, cost-effective, and high-quality products. The chosen material affects the final product’s properties, manufacturing costs, and the injection molding process itself. This guide aims to provide insights into the primary factors to consider when selecting a material for injection molding.

In the ever-evolving world of injection molding, understanding materials is paramount. They are, after all, the foundation of every molded product.

Considerations for Selecting the Right Material

1. Consider the Application

The first step in material selection is understanding the end product’s purpose. Materials used for medical devices, for instance, need to meet strict sterilization and biocompatibility standards.

2. Mechanical Properties

Different materials have different strength, elasticity, and hardness levels. Depending on the product’s desired properties, materials like ABS, polyethylene, or nylon might be suitable.

3. Cost Efficiency

While some materials may offer superior properties, they may also come at a higher price. Balancing quality and cost is essential, especially for mass-produced items.

4. Aesthetic and Finishing

Some products require a glossy finish, while others might need a matte appearance. Colors, textures, and post-molding operations should be taken into account.

5. Material Availability and Sustainability

In today’s global market, the availability and environmental impact of the chosen material are also significant. Prioritize materials that are both readily available and sustainable.

Important Properties for Injection Molding Materials

When choosing materials for injection molding, it’s crucial to understand their inherent properties. Here are some of the primary properties to consider:

1. Thermal Stability

It refers to a material’s ability to maintain its properties under high temperatures. Materials with low thermal stability might degrade or discolor during the molding process.

2. Flow Rate

This property defines how easily the material can fill the mold during injection. A high flow rate is usually desirable to ensure uniform filling and reduce imperfections.

3. Shrinkage Rate

Post-molding shrinkage can alter the final dimensions of the product. Understanding the material’s shrinkage rate ensures that the final product meets the desired specifications.

4. Chemical Resistance

For products exposed to chemicals or harsh environments, it’s essential that the material can resist degradation or discoloration.

5. UV Stability

Materials that will be exposed to sunlight or UV light should have UV stability to prevent degradation or color fading.

6. Tensile Strength

A measure of how much a material can be stretched before it breaks. This property is critical for products that will experience stretching or pulling forces.

Examine the Characteristics of Common Materials

The provided properties offer a framework that assists manufacturers and designers in better understanding the potential advantages and limitations of injection molding materials, enabling them to make informed choices.