Injection molding plays a pivotal role in this global manufacturing landscape, especially in the development of a wide range of products, from simple household items to complex automotive components. It is a manufacturing process for producing parts by injecting molten material into a mold. Injection molding supports the mass production of products with diverse materials, including plastics, metals, and composites, making it integral to various industries such as automotive, healthcare, consumer electronics, and packaging.

Outsourcing Injection Molding to China

scale, leveraging the comparative advantages of different countries to optimize costs, access advanced technologies, and tap into skilled labor markets. This international framework enables companies to produce products more efficiently, reduce production costs, and improve product quality by utilizing global supply chains and manufacturing networks.

The global nature of manufacturing means that injection molding operations can be strategically located in countries that offer the best combination of cost, quality, and logistical advantages. China, for example, has become a hub for injection molding due to its advanced manufacturing capabilities, skilled labor force, and cost competitiveness. By integrating injection molding into global manufacturing strategies, companies can leverage these advantages to enhance their product development processes, accelerate time-to-market, and achieve greater scalability and flexibility in their production operations.

The Advantages of Outsourcing Injection Molding to China

Outsourcing injection molding to China offers several compelling advantages for companies looking to enhance their manufacturing processes, reduce costs, and access a wide range of production capabilities. Here are some of the key benefits:

Cost Efficiency

- Lower Labor Costs: China’s manufacturing sector benefits from a large, skilled labor force that is available at a lower cost compared to many Western countries. This can significantly reduce overall production costs.

- Economies of Scale: The vast manufacturing infrastructure and high volume of production in China allow for economies of scale, reducing the cost per unit for injection molded parts.

- High-Quality Standards: Despite the lower cost, many Chinese injection molding manufacturers adhere to high-quality standards, matching or even exceeding international benchmarks. Senses is a company that has been certified with ISO 9001.

- Adaptable Production Capacity: Manufacturers in China can quickly scale production volumes up or down based on demand, providing flexibility that is beneficial for companies dealing with seasonal variations or testing new markets.

- Wide Range of Materials and Techniques: China’s vast manufacturing ecosystem offers access to a wide variety of materials and specialized injection molding techniques, including overmolding, insert molding, and high-precision molding.

Access to a Comprehensive Supply Chain

- Integrated Supply Chain: China’s manufacturing sector, including companies like Senses, is supported by a comprehensive and integrated supply chain, offering one-stop solutions from raw material suppliers to secondary processes like painting, plating, and assembly. Senses, with its expertise in injection molding services, exemplifies this integrated approach by providing clients with seamless, end-to-end manufacturing solutions.

- Strategic Location: China’s strategic location and established logistics networks facilitate efficient shipping and distribution to global markets, making it easier for companies to reach their customers worldwide.

Experienced Manufacturing Partners

- Expertise and Experience: Chinese manufacturers possess extensive experience in serving international clients, understanding their quality expectations, and navigating complex project requirements.

- Cultural Understanding of Global Business Practices: Many Chinese manufacturers have adapted to global business practices, including intellectual property protection, confidentiality agreements, and international communication standards, ensuring a smoother outsourcing experience.

Outsourcing injection molding to China allows companies to leverage these advantages to not only reduce costs but also enhance their product quality, speed to market, and overall competitiveness in the global marketplace.

Selecting the Right Partner in China

Selecting the right manufacturing partner in China is crucial for the success of any outsourcing project, particularly when it comes to injection molding. The right partner can ensure product quality, cost-effectiveness, and timely delivery.

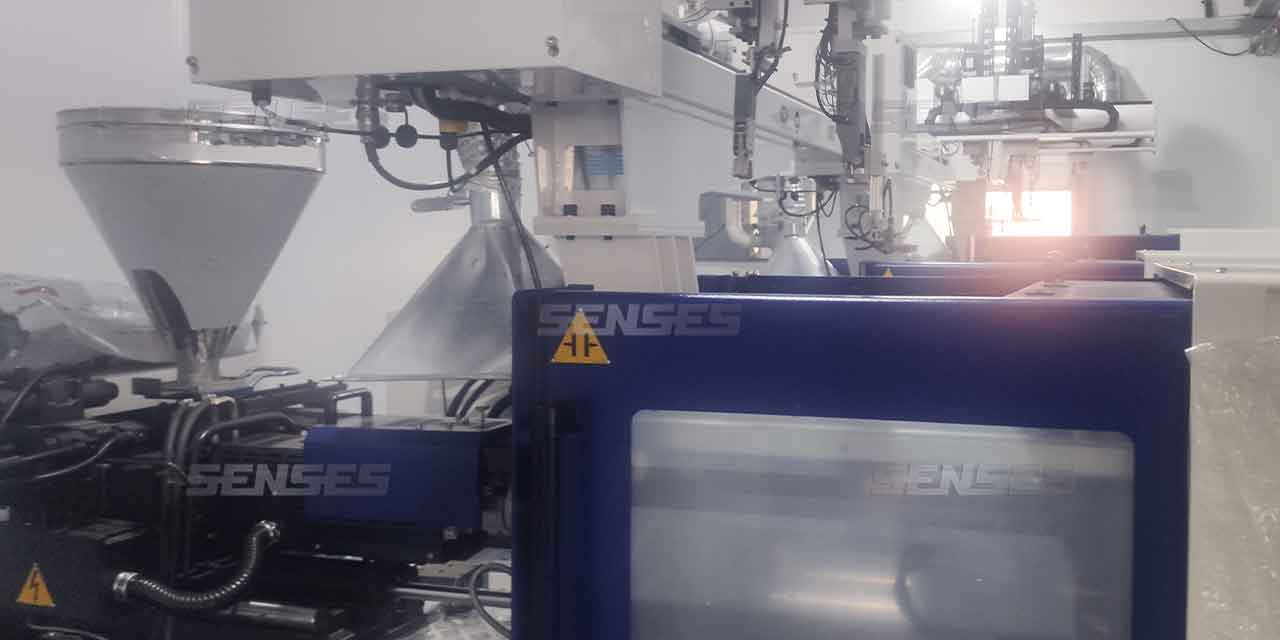

Senses: Your Partner in Injection Molding Solutions

Senses is an ISO 9001:2015 certified plastic injection molding company, offering a comprehensive array of services including mold and part design, prototyping, small-batch production, and full-scale manufacturing. We serve a diverse range of industries, encompassing automotive, medical, and consumer electronics. Our focus is on ensuring each product we deliver meets the highest standards of quality and functionality.

For personalized solutions and expert consultation, reach out to us today at info@senseschina.com.