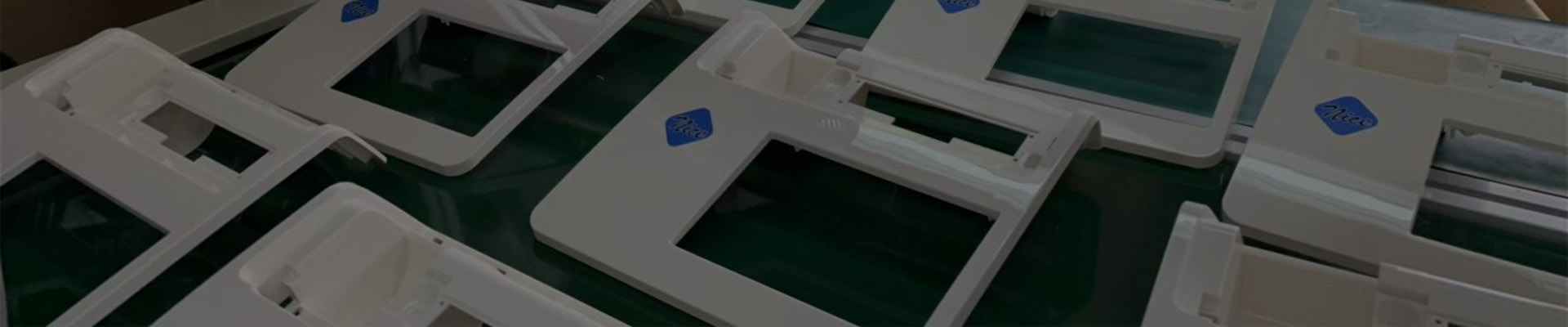

Injection Moulding Supplier. Injection molding is a manufacturing process by which molten material is injected into a mold and cured to create intricate shapes. The method is used to create parts in large quantities for use in a wide range of industries ranging from medicine to aerospace to consumer products.

At SENSES we offer injection mold prototyping services to assist our customers with testing their designs for manufacturability and functionality.

The Injection Molding Process

During the injection molding process, material is melted and mixed in a barrel where a reciprocating screw melts the material and feeds it into a split mold. The liquid material is then injected into a prototype mold cavity at high pressure to force it into all mold cavities before it cools and solidifies into the predetermined design shape.

This process is highly effective for the large scale production of industrial parts and components, and allows for the creation of products with multiple materials using repeated injection methods. Prototype injection molding wastes less material than other manufacturing processes and saves time by reducing the number of steps necessary to produce a given product.

We have been serving customers in various fields, which include Commercial/Industrial Products

Injection Moulding Supplier

Produce Simple or Complex Parts

From simple to complex, our expertise in injection molding has you covered over a very wide range of applications. Whether working with features such as undercuts, internal and external threads, thin wall molding, inserts, or overmolding, our manufacturing experts are ready to work with you to achieve your product goals. Likewise, we can mold products from a huge range of polymers, either from our extensive internal inventory or custom sourced based on your exact need.

Reduce Your Risk

We fully understand that we are producing components that are on the critical path of your product launch projects. Given the importance of delivering quality components on schedule, our technical experts are involved at every step of the process – from initial quote to final production, to ensure that your project has the highest probability of success from the moment we start.

If you’re ready to start your next project, upload your product design information for a competitive injection molding quote today. If you have any questions, please feel free to contact us at senseschina@gmail.com