Plastic Iinjection Molding Parts Factory. SENSES is professional custom plastic mold and molding company in China, Our means business is plastic mold/molding manufacturing, die casting tooling or parts, metal stamping tooling/part, part design, machining, etc. I believe this could solve most of your needs.

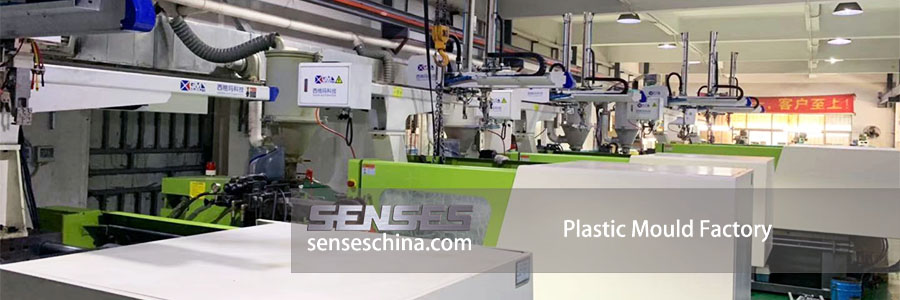

Plastic Injection Molding Factory

Plastic injection molding is our most popular plastics process to date. From cell phones to computer components, injection molding for your custom needs is the process of choice. Our fast cycle times lead to low cost parts, even when they are custom made. Injection molding is the process of melting plastic pellets and injecting the molten plastic into a mold using high pressure to form the end product. From initial part design to shipping production parts, SENSES has the capability to manage your project.

Plastic Mould Factory

Plastic Injection Molding Services

Injection molding is one of the most often-used manufacturing processes for creating plastic parts. Thanks to its high-precision, repeatability, and cost efficiency at scale, injection molding is used to make a variety of products and parts from the smallest medical insert up to large automotive & Aerospace parts.

Benefits Of Injection Molding

Custom injection molding offers a number of benefits not found in other manufacturing processes. Due to the high-pressure nature of the injection molding process, it is much easier to manufacture parts with detailed features or complex geometries that would be too costly for typical CNC machining processes. The ability to use your mold over and over again for a long period of time leads to an extremely high production output rate which is more cost effective and efficient than other manufacturing processes.

Plastic Mould Factory

Contact Us for Custom Plastic Injection Molding

If your product is still in the concept stage, you only need to present your ideas, product features and appearance requirements. Our engineers will give you the best solution, recommend the most suitable materials, and help you take the lead in the market.

We are ready and looking forward to cooperate with your next project, Contact Us Now, you will be satisfied to choose us as your partner in injection mould manufacturing& injection moulding processing.

ISO 9001:2015 and IATF16949:2016 certifications are just the beginning of our commitment to quality at SENSES. Our continuous improvement program includes identifying new technologies, improving manufacturing processes and reducing waste to deliver the highest quality injection molded components.