SENSES INTELLIGENT TECH CO., LIMITED is located at Changan Town of Dongguan City, China which is known as a famous “Manufacturing Town” neighboring Shenzhen Special Economic Zone on the east. We are well-suited with Shenzhen Airport and Humen Port just minutes away. Additionally, both of Guangzhou-Shenzhen Expressway and Beijing-Zhuhai Expressway run nearby.

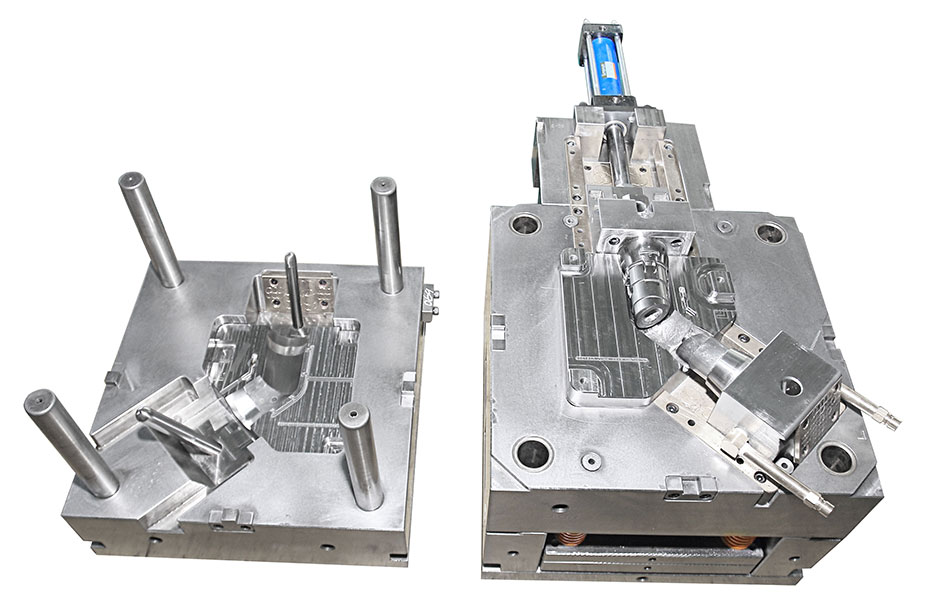

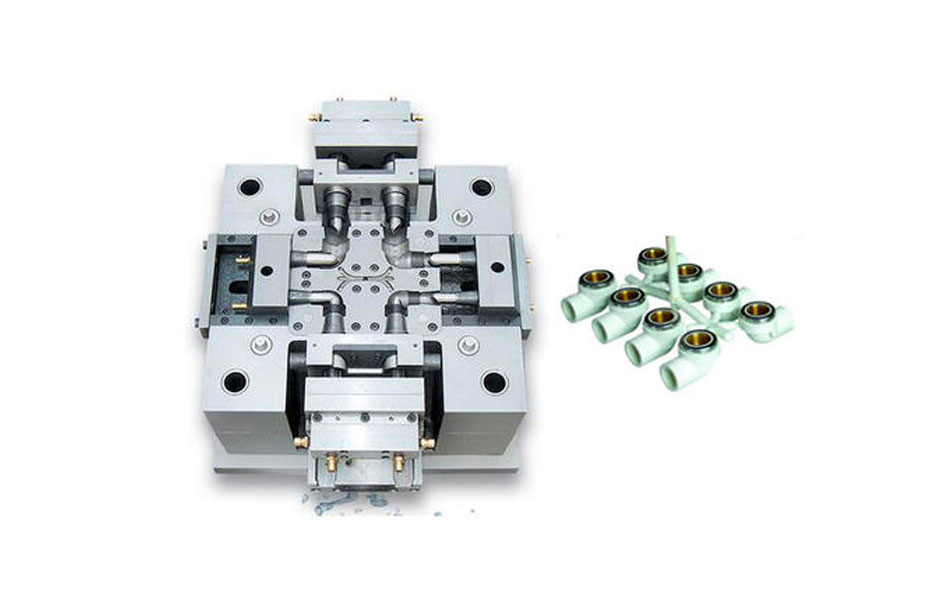

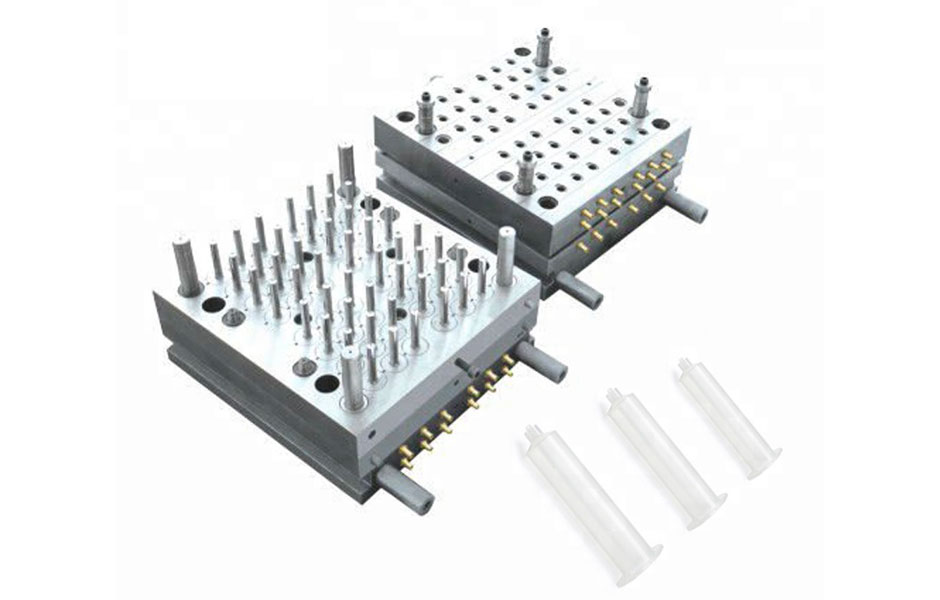

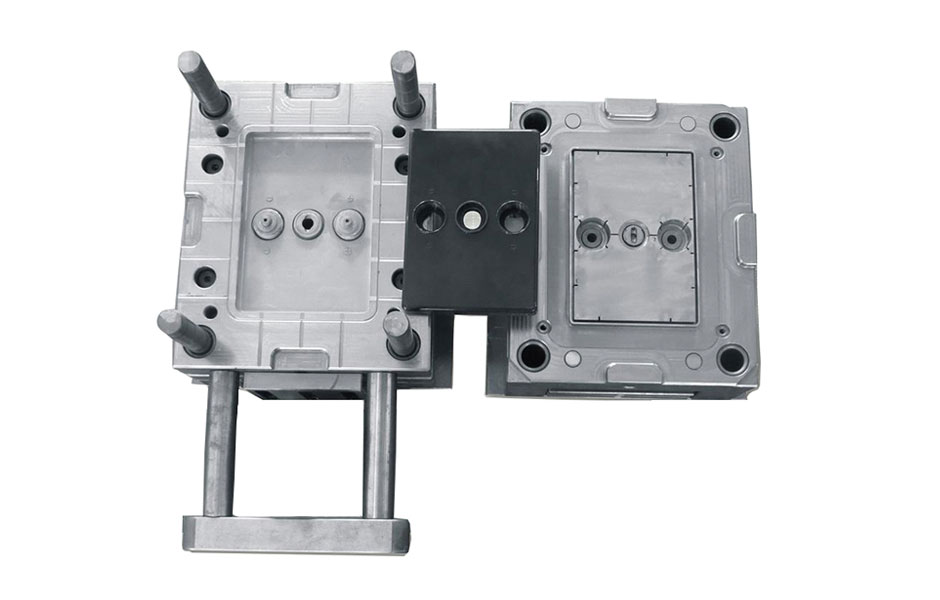

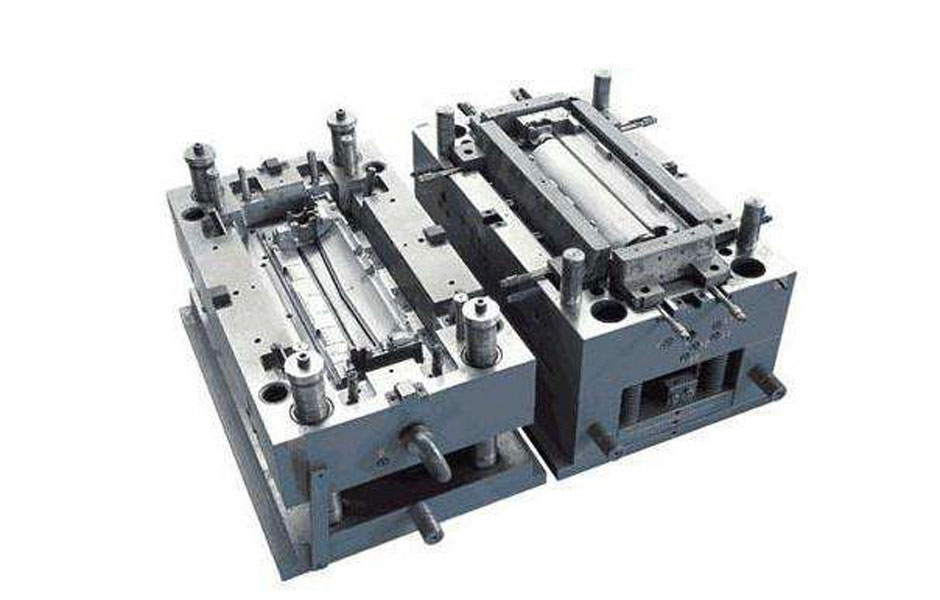

Senses is a professional mold manufacturer which are specialized in Automotive parts, Consumer Electronics, Medical Care, Household mold making. Senses ambitioned to be one of the best supplier of one stop for plastic mold making, injection molding for Automobile and other industrial; Based on this Target, we accumulated extensive experience on precision Auto mold & injection molding.

|

|

|

Automotive Injection Mould |

Appliance Injection Mould |

Precision Injection Mould |

|

|

|

Medical Device Injection Mould |

Electronic Parts Injection Mould |

Plastic Injection Moulding |

With about 120 professional staff and lots advanced equipment, we have been specialized in making and exporting molds for several years and, up to now, we have developed into a modern enterprise which is providing full-service from conception to delivery. As an excellent supplier in the line, we clearly understand what time, quality and price mean to our customers. So we spare no efforts to improve our staff, update our equipment and optimize our organization. As a result, we can always provide superior products at a competitive price in time to customers at home and abroad.

Plastic injection mold making factory. Plastic injection molds are typically constructed from hardened or pre-hardened steel, aluminum, and/or beryllium-copper alloy. Steel molds cost more but are often preferred because of their high durability. Hardened steel molds are heat treated after machining, and they are by far superior in terms of wear resistance and lifespan.

Molds are constructed through two main methods: CNC machining and electrical discharge machining(EDM).

CNC Machining

CNC machining has become the predominant means of creating more complex and accurate molds, while still using standard machining methods. With CNC, computers are used to control the movement and operation of the mills, lathes, and other cutting machines.

The mold’s mechanical dimensions are defined using computer-aided design (CAD) software and then translated into manufacturing instructions by computer-aided manufacturing (CAM) software. “Postprocessor” software then transforms these instructions into the specific commands necessary for each machine used in creating the mold. The resulting commands are then loaded into the CNC machine.

Electrical Discharge Machining

Electrical discharge machining (EDM) has become widely used in mold making. EDM is a process in which the desired shape is obtained through the use of an electrode, which is fabricated out of graphite or copper. It is then mounted in an EDM machine and positioned over the workpiece, which is submerged in a dielectric fluid.

The electrode is then lowered to the workpiece. Then, using a controlled electrical source, the electrode is used to destroy and disperse the metal in the area opposite to the electrode. The electrode never contacts the workpiece. A spark gap of a few thousandths of an inch is always maintained between the electrode and workpiece. This process is a slower method of removing metal from a mold; however, the EDM process can produce shapes that are not possible with conventional CNC machining.

If you’re ready to start your next project, upload your product design information for a competitive injection molding quote today. If you have any questions, please feel free to contact us at info@senseschina.com