At Senses China, we specialize in low volume injection molding, providing custom solutions that cater to businesses looking for high-quality plastic parts without the commitment to large-scale production. Whether you’re developing new products, refining designs, or fulfilling niche market demands, our low volume injection molding services offer the precision, efficiency, and cost-effectiveness you need.

Why Low Volume Injection Molding?

Low volume injection molding is ideal for companies that require smaller quantities of plastic components. Unlike mass production, low volume molding allows manufacturers to produce anywhere from a few hundred to a few thousand parts without the high upfront costs or long lead times typically associated with large-scale manufacturing.

This type of production is particularly beneficial for:

- Prototyping: Companies in the process of refining a product design before mass production can benefit from small batch runs to test functionality, fit, and performance.

- Custom Products: Businesses that produce specialized or custom parts for specific industries or clients may only need low volumes of each product.

- Small Market Demand: Some products are intended for niche markets, where low volume production is both practical and cost-effective.

Senses China’s Expertise in Low Volume Injection Molding

At Senses China, we understand that not every business needs mass production. Our low volume injection molding services are tailored to meet the specific needs of clients who require smaller runs while maintaining the highest standards of quality and precision.

- Custom Solutions for Every Project

Every project has unique requirements, and we specialize in providing custom low volume injection molding solutions that meet those needs. From material selection to mold design and production, we work closely with our clients to ensure that each part is crafted with accuracy and attention to detail. Whether you need small prototype batches or custom parts for a niche market, we deliver components that meet your exact specifications.

- Cost-Effective Production

One of the biggest advantages of low volume injection molding is the cost-effectiveness it offers. Large-scale production often involves expensive tooling and setup costs, which may not be practical for smaller orders. At Senses China, we offer efficient production processes and flexible tooling options that minimize costs, making it more affordable to produce smaller quantities without sacrificing quality.

- Fast Turnaround Times

Speed is often critical for businesses that are testing new products or fulfilling urgent orders. Our low volume injection molding services ensure fast turnaround times without compromising on quality. We streamline the entire production process, from initial design and prototyping to final production, so you can get your parts quickly and efficiently.

- Precision and Quality Control

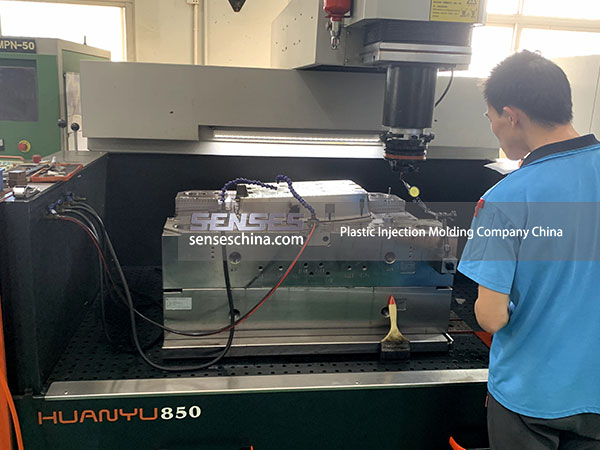

At Senses China, quality is at the core of our manufacturing process. We use advanced injection molding technology and high-precision tools to create parts with tight tolerances and consistent quality. Our rigorous quality control measures ensure that each part we produce meets the highest standards of durability and performance, even for low volume runs.

Applications of Low Volume Injection Molding

Low volume injection molding is suitable for a wide range of industries and applications, including:

- Automotive: Custom plastic components for specialized vehicles or aftermarket parts.

- Medical Devices: Small runs of medical-grade plastic parts for clinical trials or limited-release medical equipment.

- Electronics: Low volume production of plastic housings, connectors, and other components used in electronic devices.

- Consumer Goods: Custom or limited-edition plastic products for niche markets.

- Industrial Equipment: Small batch plastic parts for machinery, tools, and equipment used in specialized industries.

Why Choose Senses China?

As a leading provider of low volume injection molding services, Senses China offers several advantages to our clients:

- Customization: We tailor our injection molding services to meet your specific project needs, from prototyping to final production.

- Advanced Technology: We use the latest injection molding technology to ensure precision and efficiency in every project.

- Flexibility: Whether you need a few hundred or a few thousand parts, we can accommodate orders of various sizes while maintaining high standards.

- Quality Assurance: Our strict quality control processes ensure that every part we produce meets or exceeds industry standards for performance and reliability.

- Cost-Effective Solutions: We focus on minimizing costs while maintaining quality, making low volume production affordable for businesses of all sizes.

Partner with Senses China for Low Volume Injection Molding

If you’re looking for a reliable partner for your low volume injection molding needs, Senses China is here to help. Our expertise in custom solutions, combined with our commitment to quality and efficiency, makes us the ideal choice for businesses seeking small batch production without compromising on precision or performance.

Contact us today to learn more about how our low volume injection molding services can support your project. Email us at info@senseschina.com.