At Senses China, we specialize in providing precision automotive injection molding solutions that meet the exacting standards of this industry. With extensive experience in producing critical automotive parts, including headlights, interior connectors, and door components, we are committed to delivering custom solutions that ensure safety, performance, and longevity.

Expertise in Automotive Injection Molding

At Senses China, we understand that the automotive industry requires components that can withstand harsh conditions, including extreme temperatures, vibrations, and impacts. Our injection molding solutions are designed to produce parts that meet these challenges while maintaining the highest levels of precision and consistency.

We have worked extensively with leading automotive manufacturers to produce a wide range of plastic components, including:

- Headlights: Our precision molds ensure that each headlight is manufactured with exact measurements, delivering high clarity and durability to withstand harsh environmental conditions.

- Interior Connectors: We create custom interior connectors that are critical for the vehicle’s electrical systems. These connectors are produced with tight tolerances to ensure a perfect fit and reliable electrical performance.

- Door Components: From interior trims to door panels, we manufacture durable plastic parts that meet both aesthetic and functional requirements, ensuring long-lasting performance.

Our team of skilled engineers works closely with clients to understand their specific needs, allowing us to develop molds that produce parts with the highest level of accuracy. Whether you need small, intricate parts or larger, complex components, Senses China has the expertise and technology to deliver exceptional results.

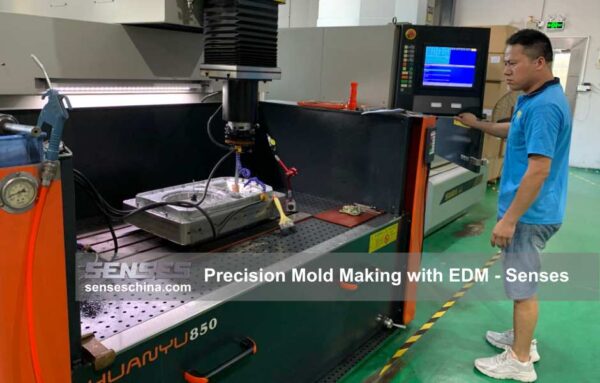

Advanced Mold Making Capabilities

A critical aspect of our automotive injection molding process is our advanced mold-making capabilities. At Senses China, we take pride in designing and fabricating high-precision molds that form the foundation of every successful injection molding project. Our mold-making process is driven by CNC machines and software that enable us to produce molds with tight tolerances and complex geometries.

Our mold-making process includes:

- Design Consultation: We collaborate with our clients during the design phase to optimize mold designs for both functionality and manufacturability. Our team ensures that the mold is capable of producing parts with consistent quality throughout the production run.

- Material Selection: We work with a variety of high-performance plastics that are specifically suited for automotive applications, including materials that offer heat resistance, durability, and impact strength.

- Prototyping and Testing: Before mass production, we offer prototyping services to validate the mold design and ensure that the parts meet all functional and aesthetic requirements.

Our commitment to precision mold making ensures that every part produced by Senses China meets the high standards of the automotive industry, whether it’s for exterior, interior, or under-the-hood components.

High-Quality Injection Molding for Automotive Parts

In addition to our mold-making expertise, Senses China offers advanced injection molding capabilities that allow us to produce automotive parts with exceptional quality. Our facility is equipped with cutting-edge injection molding machines that enable us to handle both small and large production runs efficiently.

We use advanced technology to ensure that every part produced is of the highest quality, with:

- Tight Tolerances: Automotive components require precise measurements to ensure proper fit and function. Our injection molding machines are capable of producing parts with tight tolerances, ensuring consistent quality across all production runs.

- Durable Materials: We use a range of high-performance plastics, including ABS, polypropylene, and engineering plastics, to produce parts that offer superior durability, heat resistance, and impact strength.

- Surface Finish and Aesthetics: For components such as interior trims and door panels, we provide a variety of surface finishes to meet aesthetic and functional requirements. Whether you need a glossy finish or a textured surface, we can accommodate your design preferences.

Experience in the Automotive Industry

With years of experience in the automotive sector, Senses China has built a reputation for delivering high-quality, reliable injection molding solutions for automotive manufacturers. We have worked on a wide range of projects, from producing precision connectors to manufacturing large exterior components. Our expertise allows us to handle complex projects with ease, providing our clients with the confidence that their parts will be manufactured to the highest standards.

Our experience spans various automotive applications, including:

- Headlights and Lighting: We have extensive experience in producing high-precision molds for automotive lighting systems, ensuring that each part is manufactured to provide excellent optical clarity and durability.

- Connectors and Electrical Components: We produce a range of interior connectors that are essential for the vehicle’s electrical systems. Our parts are manufactured to meet the demanding requirements of the automotive industry, ensuring reliability and performance.

- Door Components and Interior Parts: We create durable and aesthetically pleasing door panels, interior trims, and other components that contribute to the overall design and functionality of the vehicle.

Why Choose Senses China for Automotive Injection Molding?

- Advanced Technology: We use cutting-edge machinery and technology to deliver precise, high-quality parts that meet the most stringent industry standards.

- Custom Solutions: We tailor our injection molding services to meet the unique needs of each project, ensuring that every part is manufactured to your exact specifications.

- Comprehensive Services: From mold design and fabrication to full-scale production and post-production services, Senses China offers a complete solution for automotive manufacturers.

- Commitment to Quality: We implement rigorous quality control measures throughout the production process, ensuring that every part meets the highest standards of accuracy, durability, and performance.

Partner with Senses China for Your Automotive Injection Molding Needs

At Senses China, we are committed to providing automotive manufacturers with the highest quality injection molding solutions. With our expertise in precision mold making, advanced injection molding technology, and extensive experience in the automotive sector, we are the trusted partner for automotive plastic component production.

Contact us today to learn more about how our automotive injection molding solutions can support your manufacturing needs. Email us at info@senseschina.com.