Optimize your electronics and electrical component manufacturing processes with our specialized plastic injection molds. We are committed to providing precision-crafted plastic injection molds for electronics & electrical components, designed to enable high-volume production of top-quality plastic parts, suitable for a plethora of applications including, but not limited to, electronics, connectors, and enclosures.

Precision and Durability

Constructed from premium grade steel, our molds promise unbeatable durability and dimensional accuracy, ensuring consistent production results. Our expert designers optimize mold designs for fast cycle times, low scrap rates, and cost-efficient manufacturing, driving unparalleled efficiencies in electrical and electronics mold making.

Plastic: The Ideal Material for Electronic Products

Plastic resin, available in conductive or non-conductive formulations, is a superior choice for electronic products. It offers UV resistance, compatibility with watertight seals, and applicability in rigid or flexible designs, with diverse color options and design capabilities surpassing metal and other materials. The easy design and formation of plastic lower assembly costs through the incorporation of self-mating tabs, reducing the need for additional fasteners. Its competitive cost makes it an optimal choice for larger runs.

Overmolding & Additional Flexibility

We provide innovative solutions such as overmolding to combine additional materials with previously casted plastic or metal parts. This process increases flexibility and shock resistance, ensuring the production of versatile components like plugs, pin arrangements, and connectors with conductive properties.

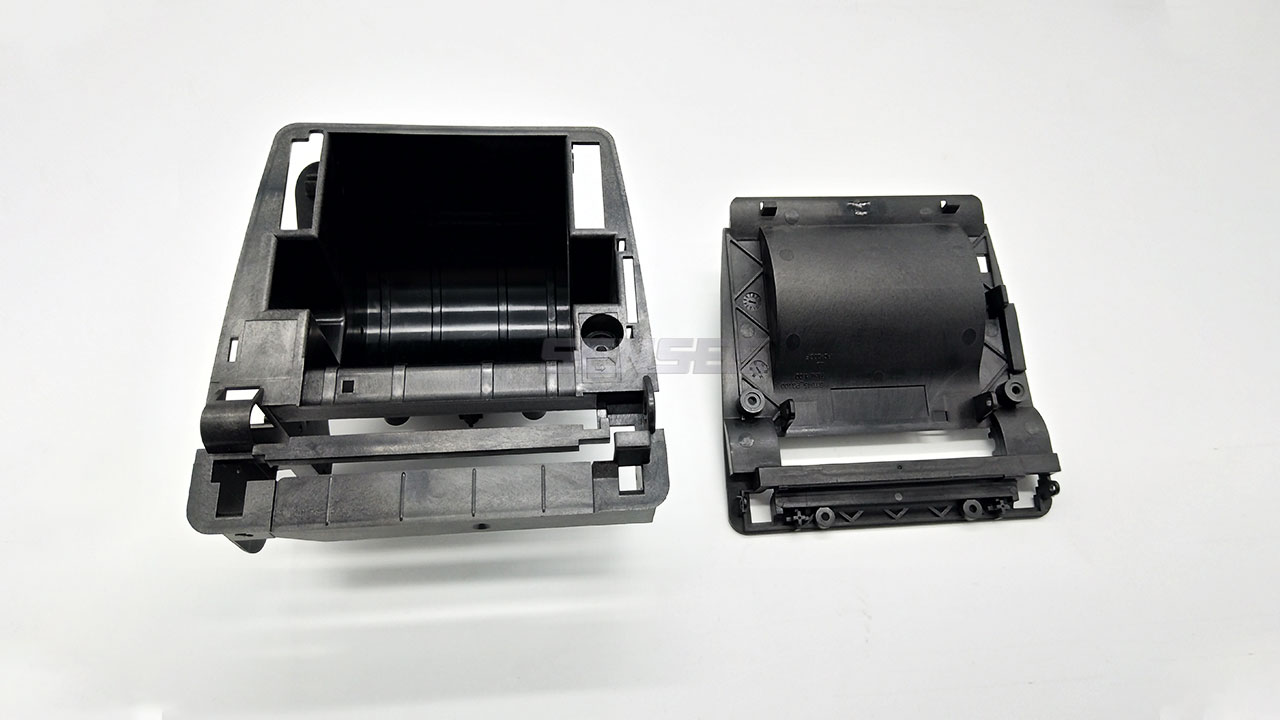

Examples of Electronic Injection Molding Products

We specialize in employing injection molding to fabricate a diverse array of products such as earphone cables and plugs, LEDs and assemblies, motor housings, and more. Our expertise in injection molding services enables the production of intricate components like electrical relays and switches, sensors, temperature controls, and inkjet printer parts, ensuring precision and quality. Additionally, we produce computer boards and housings, cell phone components and covers, electrical conduit, and tool housings, among other essential items.

Why Choose SENSES for Injection Molding Services?

We offer a comprehensive suite of services including product design, plastic injection molding services, and full-scale assembly and packaging, all meticulously tailored to transform your innovative designs into high-quality products. Our commitment is to ensure precision, quality, and on-time delivery, aligning with your project requirements.

As an ISO 9001:2015 certified entity, we uphold stringent standards of quality and compliance, offering full-service program management, seamless assembly, and integrated logistics services. Our streamlined approach is designed to optimize your manufacturing process, ensuring your production remains robust and on track, while you enjoy the convenience and reliability of our all-encompassing injection molding services.

We are here to assist you and answer any questions you may have. If you would like more information about our services, products, or have any other inquiries, do not hesitate to contact us!