Choosing a reliable China injection molding company is crucial for ensuring quality, efficiency, and durability in manufacturing. Senses China is a trusted partner in the industry, delivering exceptional injection molding services that cater to diverse industries and unique client needs. With a skilled team, advanced technology, and dedication to customer satisfaction, we provide solutions that stand out in the global market.

Expertise in Industry-Specific Injection Molding

At Senses China, we bring extensive experience across various industries, understanding the unique requirements each sector demands:

- Automotive: We produce durable components like connectors, interior parts, and trims that meet stringent safety and performance standards.

- Electronics: Our injection-molded housings, connectors, and small precision parts cater to the reliability and detail required in the electronics sector.

- Medical Devices: We manufacture high-quality, medical-grade plastic parts that comply with regulatory standards, focusing on safety and performance.

- Consumer Goods: From durable household items to specialty parts, we provide customized molding solutions that align with aesthetic and functional needs.

This industry-specific expertise allows us to meet diverse client demands, providing each project with the specialized attention it requires.

Customized Solutions for Every Project

One of Senses China’s key strengths is our ability to deliver fully customized injection molding solutions. Every project is unique, and we prioritize collaboration with clients to ensure the final product meets all specifications.

Our customization services include:

- Design Support and Consultation: From initial concept to final product, our engineering team works closely with clients to optimize designs for the molding process, maximizing both functionality and cost efficiency.

- Material Selection: We offer a broad range of materials to suit various applications, including engineering-grade plastics for durability, heat resistance, and flexibility.

- Prototyping and Testing: Before full-scale production, we offer rapid prototyping services that allow clients to test and refine their designs, ensuring optimal functionality and quality.

This tailored approach ensures that each part meets your precise specifications, whether for intricate small components or larger, high-durability items.

Quality and Precision in Every Part

Quality is central to Senses China’s mission. Our advanced molding technology and rigorous quality control processes ensure that every part we produce meets or exceeds industry standards.

Our quality control measures include:

- Precise Tolerance Testing: We ensure every part adheres to required tolerances, providing the consistency and accuracy needed for high-performance products.

- Material Verification: We conduct thorough checks on each batch of raw materials to ensure it meets client specifications and durability requirements.

- Comprehensive Inspections: Each finished component undergoes a final inspection to ensure it meets all design and performance criteria.

By emphasizing quality at each production stage, Senses China ensures reliable, long-lasting results that you can trust.

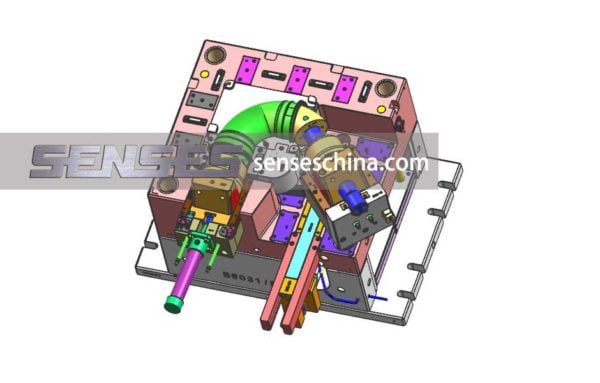

Advanced Technology for Efficient Production

Our commitment to using advanced technology enables us to produce parts efficiently without compromising on quality. Our modern facility is equipped to handle both small and large production runs, offering flexibility to meet your project timelines and scale requirements.

Our technology enables:

- High-Precision Molding: Our machinery produces parts with intricate details and complex geometries, supporting the demands of even the most technical projects.

- Quick Turnaround: Streamlined processes allow us to offer fast turnaround times, ensuring you get your parts on time and within budget.

- Cost Efficiency: By optimizing production processes, we keep costs manageable for both prototypes and high-volume orders, providing an economical solution for clients.

Why Choose Senses China?

- Customization: We offer fully tailored injection molding services to match each client’s unique requirements, ensuring functionality and aesthetic appeal.

- Industry Expertise: With a deep understanding of multiple industries, we can meet specific standards and requirements across sectors.

- High Quality Standards: Our strict quality assurance measures ensure that each part is manufactured to the highest standards.

- Technological Excellence: We leverage modern technology for precision, efficiency, and consistent production quality.

- Dedicated Customer Service: We are committed to understanding and meeting client needs, offering responsive support throughout the project.

Partner with Senses China for Reliable Injection Molding Solutions

As a leading China injection molding company, Senses China is committed to delivering quality, customized solutions that meet the needs of diverse industries. Whether you require a short-run prototype or full-scale production, our expertise and dedication make us the trusted choice for your manufacturing needs.

Contact us today to learn more about our injection molding services and discuss how we can support your project. Reach us at info@senseschina.com.