At Senses China, we pride ourselves on leveraging advanced technologies to produce top-tier injection molds and parts. Our expertise in Electrical Discharge Machining (EDM) and injection molding sets us apart, enabling us to deliver exceptional results for a variety of industries, including automotive, medical, and electronics. Senses China is a strong contender for your next precision mold making project, offering competitive rates and a proven track record of quality.

Contact us to learn more!

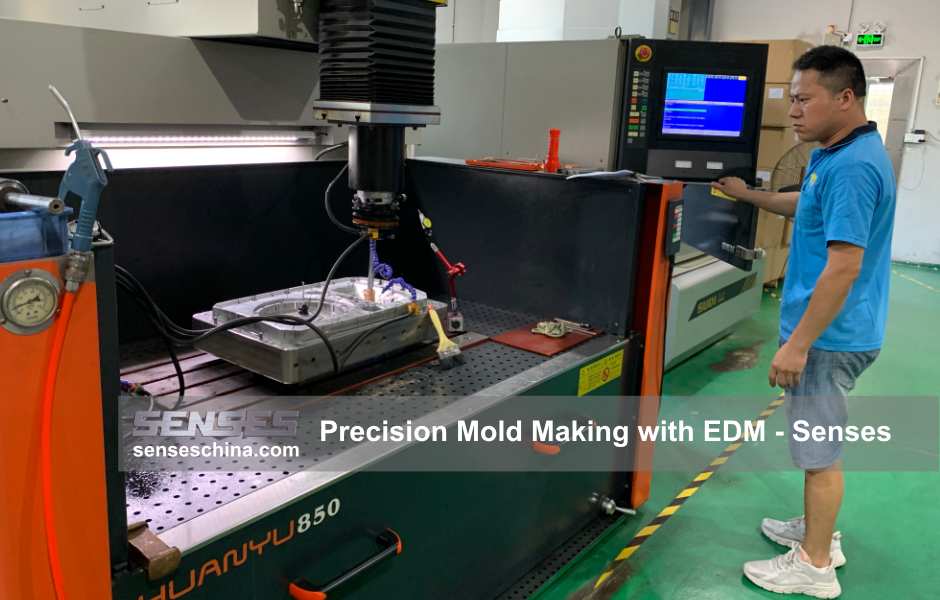

The Power of EDM Technology in Precision Mold Making

Electrical Discharge Machining (EDM) is a cutting-edge manufacturing process that uses electrical discharges to shape metal. This non-traditional machining method is particularly effective for producing intricate and precise mold components, making it an invaluable tool in the mold-making industry.

At Senses China, our technicians utilize advanced EDM machines to process molds for injection molding. The precision of EDM allows us to create complex geometries and fine details that are challenging to achieve with conventional machining methods. This capability is essential for producing high-quality injection molds that meet the rigorous demands of the automotive, medical, and electronics industries.

The EDM Process at Senses China

Our EDM process begins with a carefully designed mold component. Using a series of electrical discharges, material is removed from the workpiece, creating the desired shape with extreme precision. This method allows us to achieve tight tolerances and smooth surface finishes, which are critical for the performance and longevity of injection molds.

One of the key advantages of EDM is its ability to work with hard and difficult-to-machine materials. This flexibility enables us to create durable molds that can withstand the high pressures and temperatures of the injection molding process.

Integrating EDM with Injection Molding

The precision molds created with EDM are then used in our injection molding machines to produce high-quality parts. Injection molding is a versatile manufacturing process that involves injecting molten plastic into a mold to create a part. The accuracy of the EDM-produced molds ensures that each injected part meets exact specifications, resulting in consistent and reliable performance.

Our technicians are skilled in operating both EDM and injection molding machines, allowing for seamless integration between the two processes. This expertise ensures that the molds we create are perfectly suited for the injection molding process, optimizing production efficiency and product quality.

Quality Control and Assurance

Quality is at the core of everything we do at Senses China. Our rigorous quality control processes ensure that every mold and part we produce meets the highest standards. We conduct thorough inspections at every stage of production, from the initial EDM machining to the final injection molding. This commitment to quality ensures that our clients receive products that are reliable, durable, and precisely manufactured.

contact us to learn more!

Applications in Automotive, Medical, and Electronics Industries

The automotive, medical, and electronics industries demand components that are both high-performing and cost-effective. Our EDM and injection molding capabilities enable us to meet these requirements with precision and efficiency.

- Automotive Industry: The molds we produce are used to create a variety of automotive parts, including connectors, housings, and other critical components. The integration of EDM and injection molding ensures that these parts are manufactured to the exacting standards required by the automotive industry.

- Medical Industry: In the medical field, precision and reliability are crucial. Our molds are used to produce components for medical devices and equipment, ensuring they meet the stringent regulatory standards and performance requirements of the healthcare sector.

- Electronics Industry: For the electronics industry, we create molds for parts such as connectors, casings, and intricate components. The precision offered by EDM ensures that electronic parts are produced with the necessary accuracy and quality.

Partner with Senses China

At Senses China, we are dedicated to advancing the field of mold making and injection molding through the use of cutting-edge technologies like EDM. Our commitment to precision, quality, and innovation makes us a trusted partner for manufacturers in the automotive, medical, electronics industries, and beyond.

Contact us today to learn more about our precision mold making with EDM technology and how we can support your manufacturing needs. Email us at info@senseschina.com.