Senses China, a leader in the injection molding industry, specializes in producing high-quality plastic gears that meet the stringent requirements of various sectors, including automotive, electronics, and industrial machinery.

|

|

| senses – plastic gears |

What are Precision Injection Molded Plastic Gears

Plastic gears have become a staple in many industries due to their lightweight, corrosion resistance, and cost-effectiveness. However, producing these gears with the required precision and durability demands expertise and advanced technology. At Senses China, we excel in the art of injection molding to create plastic gears that offer excellent performance and longevity.

Advanced Techniques for Precision Injection Molded Plastic Gears

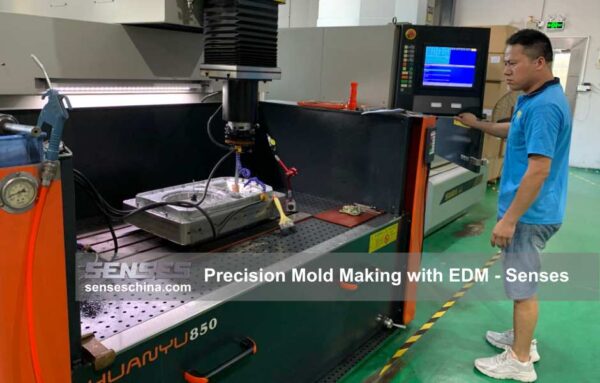

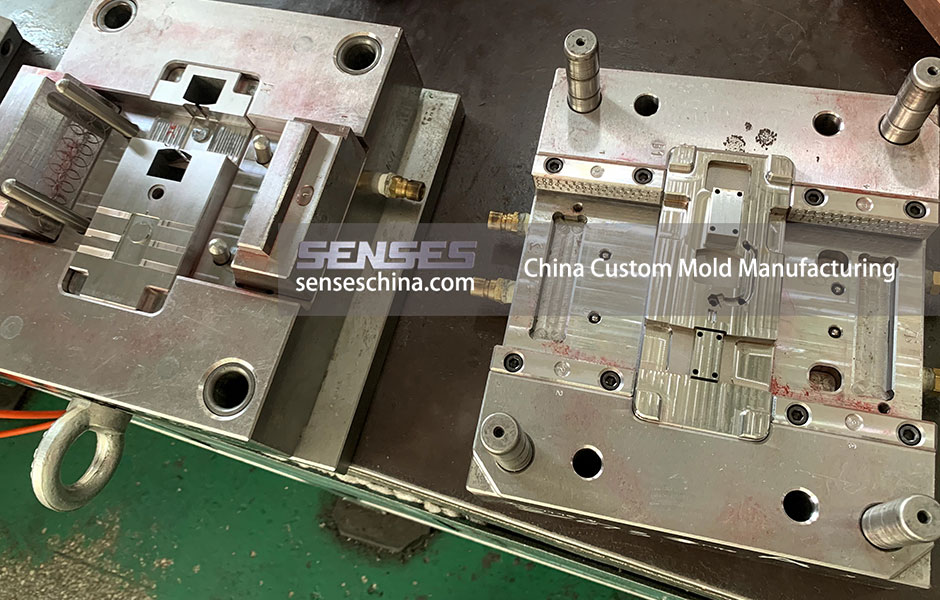

Our advanced injection molding facilities are equipped with the latest technology, enabling us to manufacture plastic gears with tight tolerances and intricate designs. The process begins with high-quality raw materials, which are carefully selected to ensure the final product’s strength and resilience. These materials are then fed into our advanced injection molding machines, where they are melted and injected into precision-engineered molds.

The molds are a critical part of the process, and our team of experienced engineers designs them to exact specifications. This ensures that each gear produced meets the required dimensions and functional characteristics. The result is a plastic gear that performs reliably even under demanding conditions.

Quality Assurance and Testing

At Senses China, quality assurance is integral to our manufacturing process. We implement rigorous quality control measures at every stage, from material selection to final inspection. Our plastic gears undergo comprehensive testing to verify their dimensional accuracy, mechanical strength, and performance under various conditions.

This commitment to quality ensures that our gears not only meet but exceed industry standards. Whether used in high-precision applications or subjected to heavy loads, our injection molded plastic gears deliver consistent and dependable performance.

Customization and Flexibility

One of the key advantages of working with Senses China is our ability to offer customized solutions. We understand that different applications have unique requirements, and our team is adept at developing tailored gear solutions that fit specific needs. From selecting the appropriate material to designing the perfect mold, we work closely with our clients to create gears that are optimized for their applications.

Our flexibility extends to production volumes as well. Whether you need a small batch of prototype gears or large-scale production runs, Senses China has the capability to meet your demands efficiently and cost-effectively.

Applications of Plastic Gears

Plastic gears are used in a wide range of applications due to their versatility and advantages over metal gears. In the automotive industry, they are found in mechanisms such as window regulators, seat adjusters, and HVAC systems. In electronics, plastic gears are integral to devices like printers, copiers, and consumer electronics. Industrial machinery also benefits from the use of plastic gears in conveyors, pumps, and actuators.

The lightweight nature of plastic gears reduces the overall weight of the machinery, leading to improved efficiency and lower energy consumption. Additionally, their resistance to corrosion and wear makes them ideal for environments where metal gears would fail.

Partner with Senses China

When it comes to precision injection molded plastic gears, Senses China stands out as a trusted partner. Our dedication to quality, innovation, and customer satisfaction ensures that we deliver products that meet the highest standards. With our advanced technology, skilled team, and commitment to excellence, we are ready to support your manufacturing needs with reliable and high-performance plastic gears.

Contact us today to learn more about our injection molding capabilities and how we can assist you in achieving your manufacturing goals. Email us at info@senseschina.com.