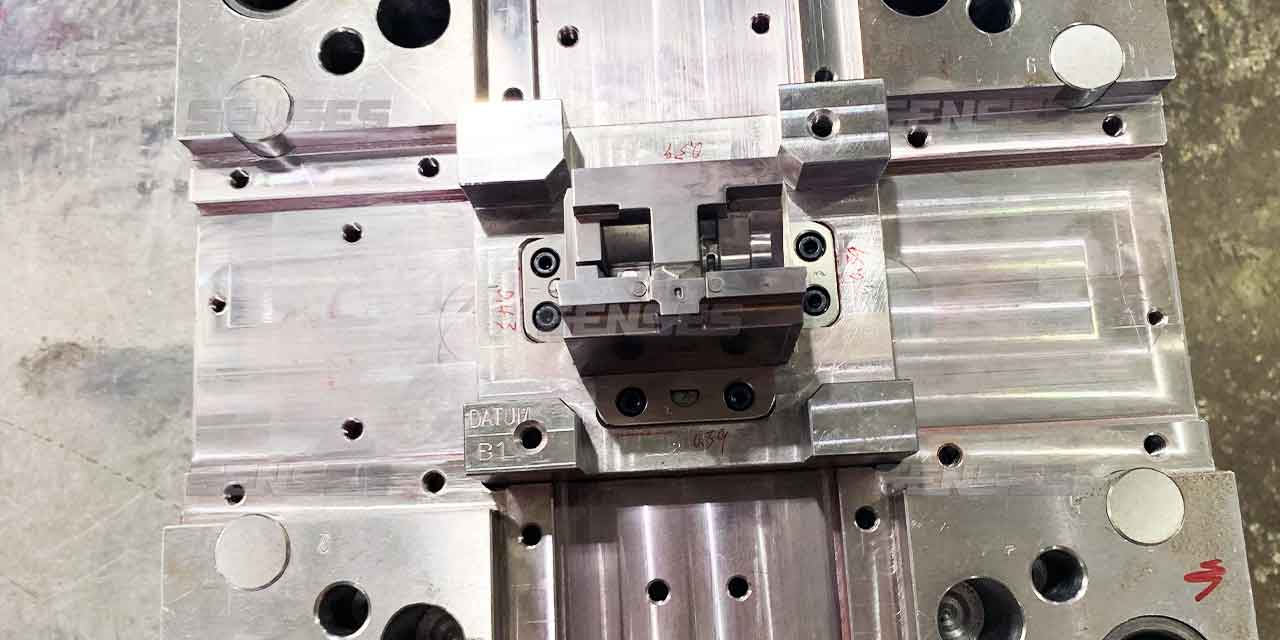

Injection molding tool steel is a key part of making plastic molds. The type of steel you choose really affects how your products turn out. It’s important to pick the right steel so the molds work well and last a long time under tough conditions.

When selecting tool steel for injection molds, it’s important to focus on several key characteristics to ensure the molds are effective and durable:

- Hardness: The steel needs to be hard enough to avoid being deformed or worn out by the molding process.

- Wear Resistance: Since the molds are used to produce a large number of parts, the steel must be resistant to wear.

- Toughness: The steel should be tough enough to avoid breaking or cracking under the stress of repeated use and the thermal shocks of the molding process.

- Thermal Stability: It’s essential that the steel can maintain its properties at high temperatures, as it will often be exposed to heat during molding. This stability helps keep the mold in good working condition.

- Corrosion Resistance: Depending on what materials are used, the steel may need to resist corrosion from the plastics or from any heating and cooling agents used in the process.

Choosing tool steel with these attributes ensures that the molds can consistently produce high-quality parts and withstand the demanding conditions of injection molding.

Common Types of Tool Steels Used in Injection Molding

Choosing the right tool steel for your injection molding projects is key to making sure your molds work well and last a long time. Below, you’ll find a table that outlines some of the most commonly used tool steels, their hardness levels, main features, and what they’re best used for. Each suited for different needs in the molding process:

| Tool Steel Type | Typical Hardness (HRC) | Key Characteristics | Suitable Applications |

|---|---|---|---|

| P20 | 28-32 | Pre-hardened, excellent machinability, good toughness | Large molds, high-volume production |

| NAK80 | 37-43 | Pre-hardened, excellent polishability, wear-resistant | High-precision molds, lens-quality transparent parts |

| H13 | 46-52 | High toughness, heat check resistance, can withstand higher temperatures | High-volume, high-temperature applications |

| 420 | 48-52 | Corrosion-resistant, high polishability, good wear resistance | Corrosive materials, medical and food-grade applications |

| 440C | 56-60 | High hardness, excellent wear resistance, corrosion-resistant | High-wear applications, processing abrasive materials |

| M2 | 60-65 | High-speed steel, very high wear resistance, good hardness at high temperatures | Small and precise molds, complex details |

| S7 | 54-58 | High impact toughness, high shock resistance, medium hardness | Molds requiring high impact resistance |

| Maraging Steel | 50-58 | Exceptional toughness, high strength, age-hardening | Very complex, high-durability molds |

| D2 | 55-62 | High wear and abrasion resistance, somewhat difficult to machine | Long run molds, high-wear conditions |

| A2 | 57-62 | Good wear resistance, excellent toughness, air-hardening | General purpose molds especially when air-hardening is required |

| O1 | 57-62 | Good wear resistance, deep-hardening, oil-hardening | Molds requiring deep hardening capabilities |

| H11 | 50-54 | High toughness, good thermal shock resistance, hot work steel | Similar to H13 but with better toughness at higher temperatures |

| CPM 10V (A11) | 59-64 | Extremely high wear resistance, powder metallurgy steel | High abrasive resistance for complex and detailed molds |

Pre-hardened Steels:

These are great for big molds where lots of parts are made. They come ready to use without needing more heat treatment, making them easier to work with and less likely to warp. Examples like P20 and NAK80 are favorites because they’re easy to shape and can be polished to a high shine.

Hot Work Steels:

If your mold will face high temperatures and pressures, hot work steels are the way to go. They can handle the heat without losing their hardness or breaking down. H13 is a popular choice here because it’s tough and resists wearing out even under tough conditions.

Stainless Steels:

These are especially good when you need to avoid rust or corrosion, like when working with corrosive materials or harsh cleaners. Steels like 420 and 440C not only resist rust but can also be polished very smoothly, which is perfect for making clear or shiny parts.

High-Speed Steels:

For molds that need to be super wear-resistant and handle really detailed, precise work, high-speed steels like M2 are used. They’re tougher and can keep sharp details well, which is ideal for smaller or more intricate molds.

Maraging Steels:

These steels are super strong and tough, perfect for complicated molds. They’re easy to shape and harden up without cracking, helping you get really detailed without problems.

Choosing the right type of steel depends on things like how many parts you need to make, how complex the parts are, and what kind of plastic you’ll be using. Picking the right one helps make sure your mold works well and lasts a long time.

Factors to Consider When Choosing Tool Steel

When picking tool steel for injection molds, here are some straightforward factors to think about to make sure you choose the right one for your project:

- Design and Details of the Part: The more complex your part is, with features like thin walls and intricate details, the better the steel needs to be at handling these fine elements.

- How Much You’ll Be Making: If you’re planning on making a lot of parts, you need steel that can take a lot of use without wearing out quickly. Durable steel is key for high-volume production to keep things running smoothly without too much maintenance.

- Type of Plastic: Some plastics are tougher on molds than others. If you’re using abrasive or corrosive plastics, pick a steel that can stand up to that wear and tear.

- Molding Conditions: Think about the heat and pressure the mold will face. Steels that can stay strong and stable at high temperatures are crucial if you’re working with high-temperature plastics.

- Lifespan and Upkeep: Consider how long you need the mold to last and how often you can maintain it. Steels that are tougher and more wear-resistant will last longer and need less upkeep.

- Cost: The price of tool steel varies, so balance the initial cost with how much you might spend on repairs or new molds down the line. Sometimes, spending more upfront can save money in the long run.

- Heat Transfer: Good heat transfer helps manage how quickly the parts cool and the overall cycle time. Steels with better heat conductivity can help make this process more efficient.

- Easy to Shape and Heat Treat: Some steels are easier to mold into the shape you need and respond better to heat treatments to reach the desired strength and durability.

Keeping these points in mind will help you choose the right steel, ensuring your mold works well and lasts as long as you need it to, all while keeping costs manageable.

Senses: Your Partner in Injection Molding Solutions

Senses is an ISO 9001:2015 certified plastic injection molding company, offering a comprehensive array of services including mold and part design, prototyping, small-batch production, and full-scale manufacturing. We serve a diverse range of industries, encompassing automotive, medical, and consumer electronics. Our focus is on ensuring each product we deliver meets the highest standards of quality and functionality.

For personalized solutions and expert consultation, reach out to us today at info@senseschina.com.