All people want to save money for new plastic injection moulding projects, it sounds easy, to increase mould quality is the best way to lower the moulding price. At Senses, it is not a problem produce 500,000 parts or more by same tool.

However, maybe you just need serveral parts to test for your moulding project. Don’t worry, because Senses also provide cost effective moulds for low quantity production, with fast lead time.

So how to reduce your injection moulding cost? Here are some ways to consider before mould making:

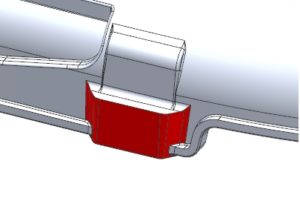

- Eliminate undercuts

- Pay attention to DFM analysis

- Use a multi-cavity or family mold

- Use exchangeable inserts

- Modify and reuse molds

Undercut, such as this picture will complicate mould structure(need slider, lifter or moving inserts), and in some case will result in the part can not release from mould. It will make higher mould price and injection moulding price, so remove it if possible.

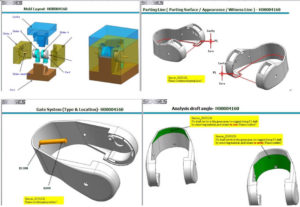

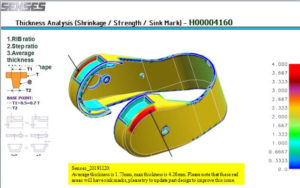

Moldability DFM Report, Senses can provide a free desin for manufacturability(DFM) report for your every injection molded part, it will show your mould structure, parting lines, gate positions, ejector pins, draft angle, thickness etc…Senses will provide professional suggestions if your drawing has problems.

Multi-cavity or family mold, If you need high volume of injection moulding parts, we can consider to do mould cavities such as 2 cavites, 4 cavities, 8 cavities according to part dimensions and structure. With this way can help to save moulding cost .

If you have different parts with same material, similar size and structure, we suggest to make them in save mould to save mould and injection moulding cost.

Exchangable insert, Maybe you need another very similar part after first one? you can do an exchangeable insert for different versions. There’s no reason to build a mold for each simillar part with more additional cost.

Modify and reuse molds,Maybe you need improve your part function by doing design changes? We can do the changes on current tools such as remove metal, add metal or othery easy ways..

Any questions? Feel free to contact us at 86-769-82380826, or marketing@senseschina.com.