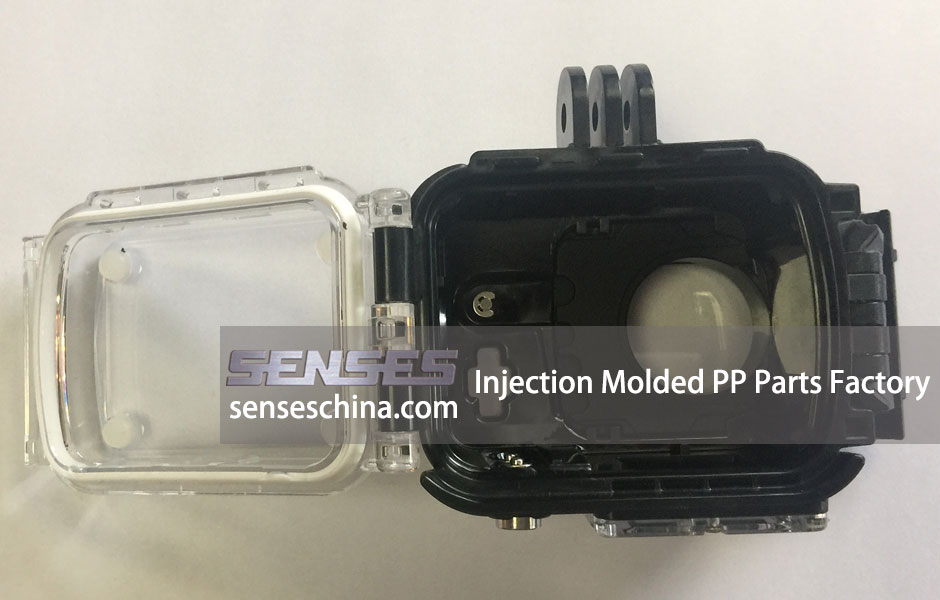

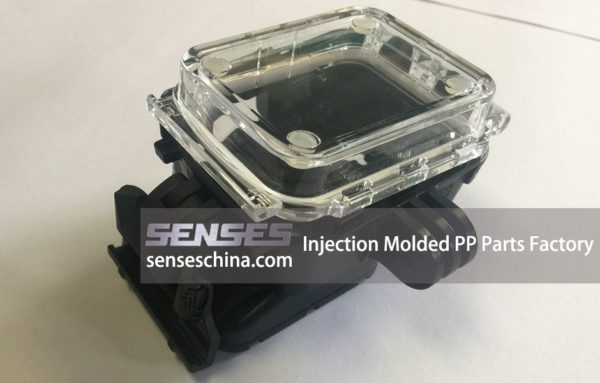

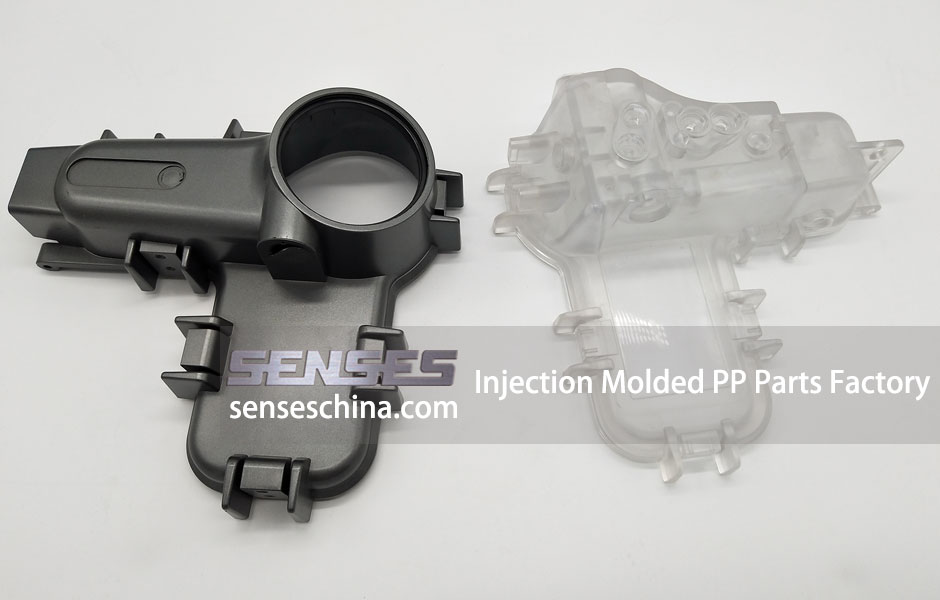

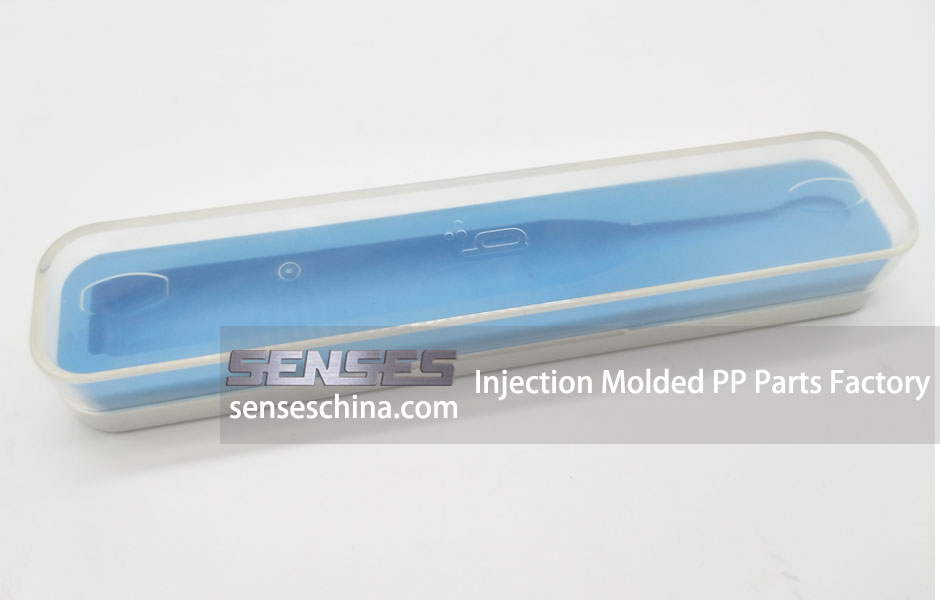

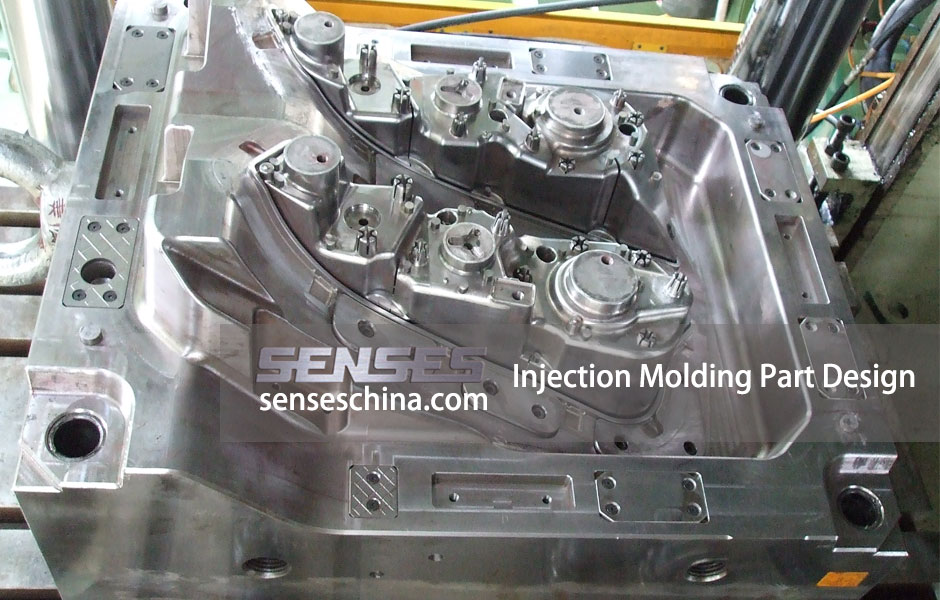

Injection Molded PP Parts Factory. At Senses, our focus is on providing you with the finest services in design products, rapid prototyping, tooling design & manufacturing, injection molding services, products manufacturing, assembly.

Our team of engineers and technicians are dedicated to making your custom products using the most advanced equipment and techniques including 3D printing, multi-axis CNC machining and plastic injection molding. We’re here to turn your ideas into reality quickly, accurately and at a great price. Start your project now!

We have been serving customers in various fields, which include Commercial/Industrial Products

- Auto Parts

- Casting Parts

- Cigarette Series

- Clear Parts

- Electrical Equipment

- Electronic Tools

- Soft Material Parts

- Medical Products

- Hardware Products

We offer a range of materials for your mold tools and injected parts. There are thousands of thermoforming and thermosetting plastics to choose from for your project. In addition, mechanical and chemical characteristics can also be enhanced with additives like glass fibers, UV stabilizers and lubricants.

At Senses we specialize in producing high-quality plastic injection molded parts and mold tools. We offer machining and finishing services to make tools from a variety of materials, and can produce 50 to 100,000+ finished parts in a wide variety of plastics.

Plastic injection molding is by far the most common way to produce large volumes of finished plastic parts for every kind of commercial and industrial use. Molten resin is injected under high pressure into the cavity of a metal die and then rapidly cooled, forming a solid shape. A single cycle to make a finished part may take anywhere from a few seconds to minutes depending on part complexity and size.

Contact Senses

If you’re ready to start your next project, upload your product design information for a competitive injection molding quote today. If you have any questions, please feel free to contact us at senseschina@gmail.com