Plastic injection molding is still the fastest and most economical way to make thousands or even millions of plastic parts for every conceivable application. To get the best results requires a thoughtful application of sound design principles early in the product development stage.

Part design is a critical aspect of injection molding, essential for creating high-quality components in a cost-effective manner. In injection molding, where melted material is injected into molds, the design of the part significantly impacts the manufacturing process. It affects material usage, production costs, and the final product’s quality and accuracy.

This article explores the importance of good part design in injection molding. We’ll discuss key factors and practical tips for engineers and designers to consider.

Design Considerations for Injection Molding Parts

Thoughtful part design is fundamental for achieving optimal results. Every aspect of a part’s design influences its manufacturability, performance, and cost-effectiveness. From the geometry of the part to the selection of materials and the intricacies of dimensional accuracy, careful consideration at the design stage can make a significant difference in the success of the molding process.

In this section, we will delve into various design considerations that are essential for injection molding parts. We will explore factors such as part geometry, material selection, tolerances, surface finish requirements, and gate and runner design. By understanding these considerations and incorporating them into the design process, engineers and designers can ensure smoother production processes, higher quality parts, and ultimately, greater satisfaction for customers.

Wall Thickness

Maintaining uniform wall thickness throughout the part is essential to ensure proper filling of the mold cavity and prevent issues like sink marks, warping, and uneven cooling.

- Consistency: Keeping wall thickness uniform is important because it helps ensure that the plastic flows evenly during the injection process. If the walls are uneven, the part might cool inconsistently, leading to issues like warping or sink marks.

- Material Guidelines: Different materials have specific recommendations for minimum and maximum wall thicknesses. These guidelines help ensure that the material can fill the mold properly and cool effectively, maintaining the strength of the finished part. For example, materials like ABS typically have a minimum wall thickness recommendation of around 1.2 mm.

- Cooling Rate: Thicker walls hold heat longer, which can slow down the cooling process. This can increase production time and energy use, making the process less efficient. Designers often work to find a balance between the necessary strength of the part and the desire for quick production cycles.

Design Techniques for Managing Thickness:

- Core Out Areas: Areas of the part that do not require high strength can be cored out to reduce thickness and material usage, which also aids in faster cooling.

- Using Gussets: Where strength is needed but increased thickness is impractical, adding gussets can help support and reinforce the part without significantly impacting the cooling rate or material flow.

- Gradual Transitions: Abrupt changes in wall thickness can cause stress concentrations and aesthetic defects. Gradual transitions help maintain a smooth flow of plastic and reduce the risk of defects.

By paying careful attention to wall thickness in the design phase, engineers can avoid many common production problems, optimize the use of materials, and ensure that the final product meets all functional and aesthetic requirements.

Draft Angles

Draft angles are a fundamental aspect of design in injection molding, as they facilitate the removal of the part from the mold.

- Purpose of Draft Angles: Draft angles are slight tapers applied to the vertical faces of a part to allow it to be ejected more easily from the mold. Without adequate draft, parts may stick inside the mold, causing damage during ejection or slowing down production with the need for manual intervention.

- General Guidelines: The recommended draft angle depends on the depth of the part and the surface finish. For instance, a standard draft angle might start at about 0.5 degrees for shallow parts but could need to be larger, up to 3 degrees or more, for deeper or more complex molds. Textured surfaces typically require larger draft angles to ensure that the texture doesn’t cause the part to stick to the mold.

- Impact on Aesthetics and Functionality: While draft angles are primarily functional, they also have an aesthetic impact. Proper draft helps maintain the integrity of the part’s appearance, preventing deformation. On functional aspects, especially with parts that stack or fit together, draft angles need to be precisely calculated to ensure proper fit and function after ejection.

Fillets and Radii

These rounded features help spread out stress more evenly, which is especially important to prevent cracks or breaks where parts are under load. They also make it easier for the molten material to flow during injection, leading to better consistency and fill quality.

- Keep It Consistent: Try to use uniform fillet and radius sizes throughout the part to ensure even flow and cooling. This consistency helps keep the part stable in shape and appearance.

- Size Matters: The right size for a fillet or radius depends on the part’s overall size and how much load it needs to handle. Generally, larger loads might require bigger fillets.

Ribs and Bosses

Ribs provide additional strength and stiffness to the part without significantly increasing material usage. However, they should be designed with proper thickness and rib-to-wall ratios to avoid sink marks and maintain structural integrity. Similarly, bosses—projections on the part for mounting or fastening purposes—should be adequately designed to prevent issues like sink marks and warping.

- Placement and Size: When adding ribs, it’s crucial they’re correctly positioned and sized to offer support where it’s most needed without creating areas of excessive thickness that can cause issues like sink marks. Similarly, bosses should be proportionate to the loads they’ll bear and include appropriate features for fastening, like threads or knurls.

- Thickness and Height: Generally, ribs should not be thicker than 60% of the adjoining wall to avoid uneven cooling and internal stresses. For bosses, the base should be designed with radii and gussets if necessary to prevent stress concentrations and to improve attachment strength.

Practical Considerations:

- Draft Angles: Just like other parts of the design, ribs and bosses should have draft angles to facilitate easy mold release. The angle will depend on the orientation of the rib or boss relative to the mold opening.

- Reinforcements: Adding gussets at the base of ribs and bosses can further enhance their strength and reduce the likelihood of failure under load.

Material Selection

Here’s a straightforward guide on what to think about when picking materials for your injection molding projects:

1. Material Properties:

- Strength and Stiffness: Different projects need different levels of toughness. For example, parts for cars need to be very strong to handle impacts, while household items might need to be less robust but still look good.

- Temperature Resistance: Some materials need to withstand high temperatures without warping or melting. Materials like polycarbonate are good choices for these situations.

- Chemical Resistance: If the part will be exposed to chemicals or harsh environments, choosing materials like polypropylene can prevent damage and degradation.

2. Aesthetics:

- Color and Texture: Many materials can be colored directly in the molding process, which can save time compared to painting them later. You can also choose materials that mold well with textures.

- Transparency: For parts that need to be see-through, such as protective covers or light fixtures, clear materials like acrylic work well.

3. Processing Characteristics:

- Melt Flow: It’s important to choose a material that can flow into the mold properly, especially for intricate designs or thin parts. The melt flow index of a material tells you how easy it is to mold.

- Shrinkage: All materials shrink a bit as they cool down. Knowing how much a material shrinks helps ensure that the final part sizes are accurate.

4. Cost Considerations:

- Material Cost: Material prices vary a lot. While high-performance materials offer better properties, they also cost more. It’s important to balance the need for performance with your budget.

- Manufacturing Efficiency: Some materials might need special conditions like higher temperatures or unique cooling methods, which can make the manufacturing process longer or more expensive.

Selecting the right material for injection molding involves considering how the material will perform during and after the molding process and ensuring it meets your project’s needs in terms of function, appearance, and cost.

Properties of Common Injection Molding Materials

In injection molding, selecting the right material is crucial for achieving desired performance, appearance, and cost-effectiveness. Here’s a brief overview of some commonly used materials and their key properties:

Polyethylene (PE):

- Versatility: Available in various types, including high-density (HDPE) and low-density (LDPE), offering flexibility for different applications.

- Chemical Resistance: Resistant to many solvents and chemicals, making it suitable for diverse environments.

- Flexibility: LDPE is more flexible, while HDPE provides better stiffness.

- Applications: Often used in packaging, containers, toys, and household items.

Polypropylene (PP):

- Strength and Flexibility: Strikes a balance between strength and flexibility, ideal for durable yet resilient parts.

- Chemical Resistance: Resists acids, bases, and organic solvents, suitable for various applications.

- Heat Resistance: Withstands high temperatures without deformation, suitable for indoor and outdoor use.

- Applications: Commonly found in automotive components, food containers, medical devices, and consumer products.

Acrylonitrile Butadiene Styrene (ABS):

- Strength and Impact Resistance: Exhibits good impact resistance and toughness, making it suitable for demanding applications.

- Surface Finish: Accepts paint and adhesive well, providing a smooth finish for aesthetic products.

- Temperature Resistance: Offers moderate heat resistance, suitable for various temperature ranges.

- Applications: Used in automotive parts, electronic housings, toys, and consumer goods.

Polycarbonate (PC):

- Transparency: Naturally transparent with excellent optical clarity, ideal for applications requiring visibility.

- Strength and Toughness: Demonstrates exceptional impact resistance and toughness, suitable for challenging environments.

- Temperature Resistance: Withstands high temperatures without deformation, suitable for heat-exposed applications.

- Applications: Commonly employed in eyewear, automotive components, medical devices, and electronic housings.

Polyethylene Terephthalate (PET):

- Clarity: Transparent with good optical properties, enhancing visual appeal in packaging applications.

- Strength: Displays high tensile strength, suitable for durable applications.

- Chemical Resistance: Resistant to solvents and chemicals, ensuring product integrity in various environments.

- Applications: Used in beverage bottles, food packaging, and textile fibers.

Understanding these basic properties can aid in selecting the appropriate material for specific injection molding applications, ensuring optimal performance and quality in the final products.

Efficient Design for Injection Molding

When designing parts for injection molding, simplicity is key. Keeping designs straightforward while meeting functional needs helps streamline production and minimize costs. It’s essential to maintain uniform wall thickness throughout the part to ensure consistent material flow during molding, reducing the risk of defects like warping or sink marks. Incorporating draft angles on vertical surfaces facilitates easy mold ejection, improving efficiency and reducing the chance of damage.

Rounded edges and fillets play a crucial role in distributing stresses evenly across the part, enhancing strength and reducing the risk of stress concentration. Additionally, they promote smoother material flow during molding, contributing to better overall part quality. Considering the capabilities and limitations of the injection molding process during design helps avoid challenges such as undercuts or intricate details that may complicate production.

By optimizing part geometry and balancing aesthetics with functionality, designers can create parts that are efficient to manufacture and meet performance standards. Prototyping and testing allow for iterative improvements, ensuring that final designs are both manufacturable and effective. Efficient part design not only benefits the manufacturing process but also contributes to the success of the end product.

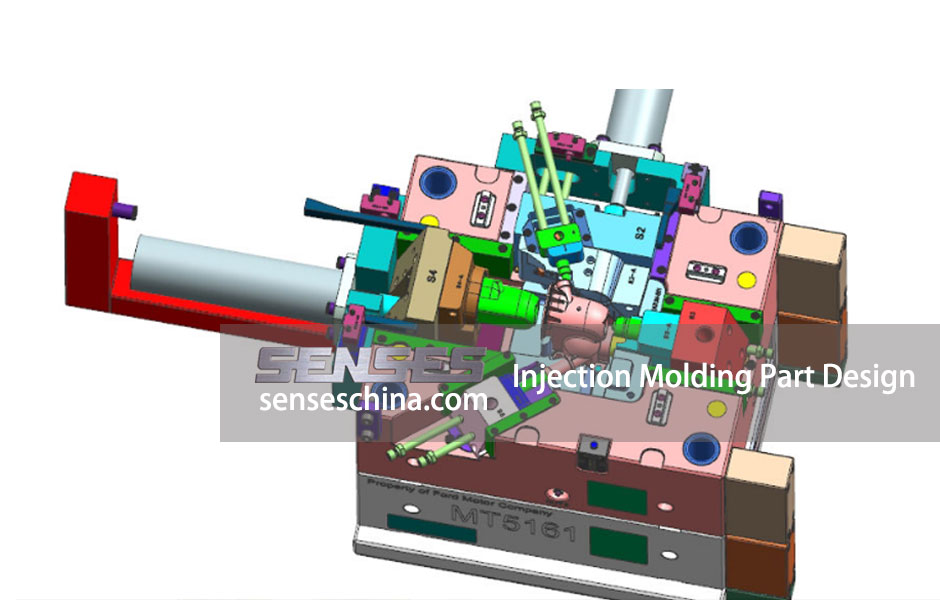

Senses: Your Partner in Injection Molding Solutions

Senses is an ISO 9001:2015 certified plastic injection molding company, offering a comprehensive array of services including mold and part design, prototyping, small-batch production, and full-scale manufacturing. We serve a diverse range of industries, encompassing automotive, medical, and consumer electronics. Our focus is on ensuring each product we deliver meets the highest standards of quality and functionality.

For personalized solutions and expert consultation, reach out to us today at info@senseschina.com.