Correct injection mold design is crucial to having a profitable business. A proper design will ensure quality plastic parts will be produced for the intended life of the mould at the expected cycle time.

Correct injection mold design has the following benefits:

- Quick mold setups

- Faster cycle times

- Quality parts

- Low reject rate

- High productivity

- Long mold life

- Long molding machine life

- Higher employee morale

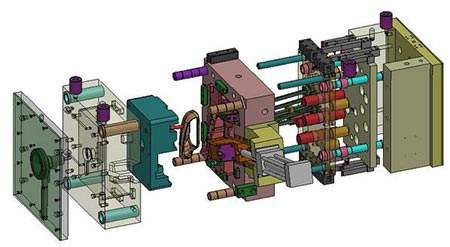

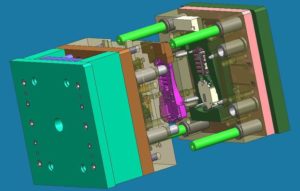

Unfortunately, many mold designs have some fundamental flaws which prevent the injection molder from achieving a higher level of productivity. Most molds have 2 back plates with one on the fixed side and one on the moving side.

The back plates have 3 main functions:

- To hold the mold in the moulding machine using clamps

- To form part of the runner system

- Support the entire mould against excessive platen deflection

If the back plates are too thin then the resultant repetitive deflection during each cycle eventually causes the following part quality problems:

- Flashing

- Shorting

- Weight variation

- Voids

- Sink

- Balancing issues

These quality problems occur because the platens do not provide enough support to stabilize the mould against cavity injection pressure and clamp tonnage.

What’s more, repetitive deflection causes wear inside the mould. One of the things mould wear does is reduce the effectiveness of the venting. Poor venting will also result in reject parts – especially in multi cavity moulds.

It’s important to keep in mind that during the injection molding process most machines will have some amount of platen deflection. Platen deflection is not necessarily a bad thing, however, if the deflection is extreme then part quality will deteriorate over time. This can happen over a period of years, months or weeks depending upon the injection mold design and selection and condition of the moulding machine.

Platen deflection is usually worse on the fixed side platen because of the weakness created by the location ring diameter and the larger recess behind it. The diameter is quite large in most machines as it is clearance to allow the machine injection unit nozzle to connect to the mould.

Have a question about Mould Design? Have any new plastic injection mould project? Are you looking for a mould supplier with good engineer team in China? All you need to do is Contact us at yoyo@senseschina.com today..