Plastic Injection Molds Classification very depend on what we need to make the plastic parts, because every parts have specific and unique design. when design molds we must see what the influencing factor like geometry, number of cavities, ejection principle, plastic material and shape of parts.

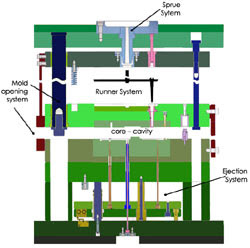

The basic classification of mold based on construction shown on picture below:

1, Two-plate mold

When opening the mold, the moving half and the fixed half are separated, thus taking out the plastic parts, which is called Two- plate mold. It is the simplest and most basic form of injection mold. It can be designed into single-cavity injection mold or multi-cavity injection mold according to the needs. It is the most widely used injection mold.

2, Three-plate mold

Basically three plate molds has two parting line, compared with the two-plate mold, the three-plate mold adds a locally movable middle plate (also known as the movable gate plate, which is equipped with gates, runners and other parts and components needed for the fixed half). It is often used for single-cavity or multi-cavity injection moulds with point gate feed. When opening the mold, the middle plate is separated from the fixed half at a fixed distance on the guide post of the fixed half, so that the condensate of the gating system can be removed between the two plates. The structure of the three-plate mold is complex, the manufacturing cost is high, and the processing of parts is difficult, so it is generally not used for the molding of large or super-large plastic products.

3, Slide mold

When the plastic part has a side hole or a side concave, it is necessary to use a laterally movable core or slider to form. After injection molding, the moving mold first moves downward for a certain distance, and then the bevel section of the bending pin fixed on the fixed template forces the slider to move outward, while the push rod of the demoulding mechanism pushes the push plate to remove the plastic part from the core.

4, Mold with Screw Device

For the plastic parts with threads, when the automatic demoulding is required, a rotating thread core or ring can be set on the mold, and the mold opening action or the rotating mechanism of the injection molding machine can be used, or a special transmission device can be set up to drive the thread core or thread ring to rotate so as to extricate the plastic parts.

5, Split Cavity Mold

Because of some special structures of plastic parts, the injection mold is required to set movable molding parts, such as movable punch, movable concave die, movable insert, movable threaded core or ring, etc., which can be removed from the mold together with the plastic parts during demoulding and then separated from the plastic parts.

Above are simple introduction for plastic Injection Molds Classification. If you are in need of any projects, feel free to contact us.