Plastic injection molding is pretty much the unsung hero of the manufacturing world. Imagine this: you have a design for a part—maybe something for a car, a new toy, or even a component for your coffee maker. How do you turn that idea into something real, and lots of them, fast? That’s where plastic injection molding comes in.

This process isn’t just about speed, though. It’s a chameleon, allowing for all sorts of materials and colors, making parts that can be strong, flexible, clear, or colorful. It’s how we get so many of the products we use every day, from gadgets and toys to important bits in cars and medical devices. In a nutshell, plastic injection molding is like a magic machine, turning ideas into real, tangible things by the thousands, and it’s pretty cool when you think about it.

Importance of plastic injection tooling in manufacturing

First off, it’s all about making things perfectly, every single time. A good mold means every piece comes out just right, fitting together like pieces of a puzzle. This is super important, especially when you’re making things that need to be exactly the same, like car parts or medical gadgets.

Then, there’s the speed factor. With the right mold, you can pump out hundreds or thousands of parts in no time. This not only keeps up with everyone wanting your product but also helps keep things affordable. Speaking of materials, tooling is like a chameleon—it can handle all sorts of different plastics. Whether you need something tough, clear, or flexible, tooling makes it possible.

Cost-wise, spending a bit more on a good mold upfront can save a lot of money down the line. Durable molds last a long time, cranking out loads of parts without needing a break. Plus, it’s kinder to the planet. The process doesn’t waste much plastic, and the parts last longer, meaning less junk.

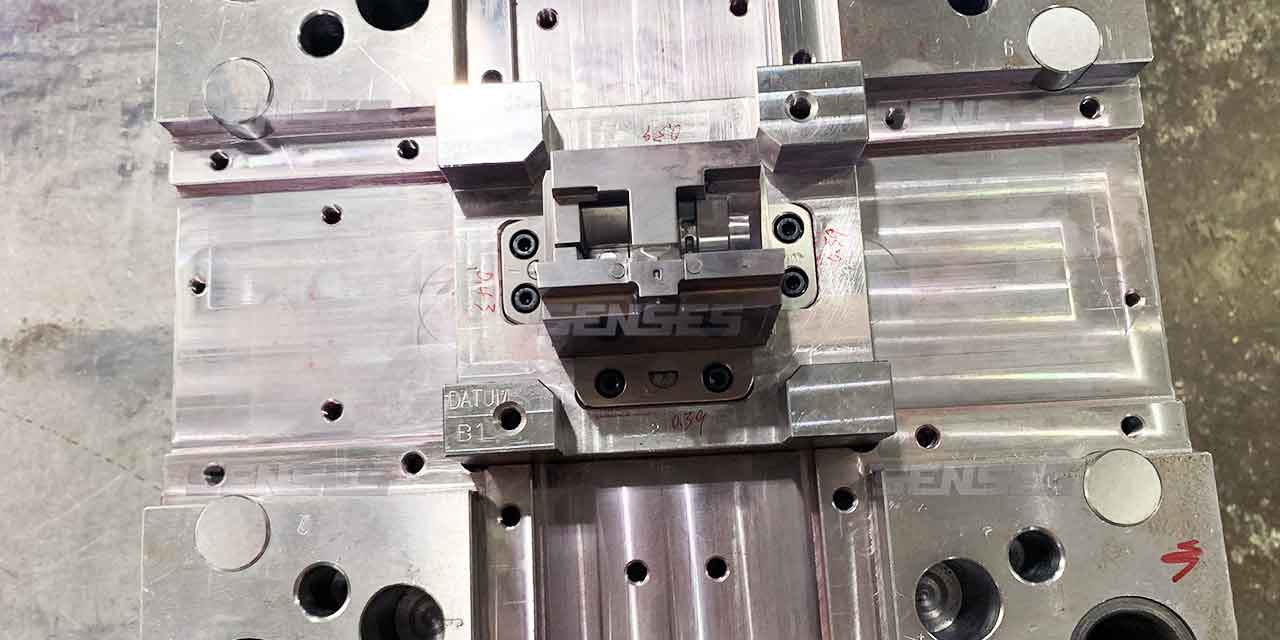

The role of tooling in plastic injection molding

Here’s the gist: you take plastic, melt it until it’s gooey, then squirt it into a special mold that’s shaped like your part. Let it cool off, open up the mold, and voila, your part is ready. And the best part? You can do this over and over again, super fast, making tons of identical parts.

Overview of the plastic injection molding process

Plastic injection molding is like a modern-day alchemy, turning raw plastic into just about any shape you can imagine, from toys and phone cases to car parts and medical devices. Here’s a rundown of how it all happens:

- Designing the Mold: It all starts with a mold, which is basically a custom-designed container that gives the plastic its shape. Designing a mold is a big deal—it needs to be perfect because it decides what the final part will look like.

- Choosing the Plastic: Next, you pick the type of plastic. There are tons to choose from, each with its own superpowers—some are tough, some are flexible, and others might be heat resistant or food safe.

- Melting the Plastic: The chosen plastic, usually in the form of small pellets, is fed into the injection molding machine. It gets heated until it’s all melty and gooey, ready for molding.

- Injection: Now comes the cool part. The molten plastic is injected into the mold at high pressure. This is where the magic happens—the liquid plastic fills the mold, getting into all the nooks and crannies.

- Cooling and Solidifying: The plastic needs a bit of time to cool down and solidify, transforming from its liquid state into the solid shape of the mold.

- Ejecting the Part: Once the plastic has cooled and hardened, the part can be ejected from the mold. Sometimes it might need a little push to come out, but once it does, you’ve got yourself a brand-new plastic part.

- Repeat: The beauty of plastic injection molding is that you can do this process over and over again, making hundreds or even thousands of parts in a relatively short amount of time.

The whole process is a fine balance of art and science, requiring precision engineering and design, not to mention a bit of patience. But the end result? You can create durable, complex parts at a scale and speed that other manufacturing processes can’t match. That’s what makes plastic injection molding such a big deal in the manufacturing world.

Types of Plastic Injection Tooling

Here’s a quick dive into some of the main types of plastic injection tooling out there:

1. Single Cavity Mold

A mold with only one cavity, meaning it can produce one product per injection cycle.

Best for: Low-volume production or prototypes where precision and detail are critical.

2. Multi-Cavity Mold

A mold that has multiple cavities of the same part, allowing it to produce several parts per injection cycle.

Best for: High-volume production where consistency across parts is essential.

3. Family Mold

A mold designed with multiple cavities, each for a different part of a product or assembly.

Best for: Producing components of an assembly in one go, saving time but requiring precision in design to ensure all parts fit together.

Design Considerations for Injection Molds

Several key considerations need to be balanced during the design phase to optimize the mold for functionality, quality, and cost-effectiveness. Here’s a rundown of essential design considerations for injection molds:

Material Selection

The choice of plastic material affects the mold design, including the type of steel used for the mold, cooling requirements, and surface finish. Different plastics have varying flow rates, cooling times, and shrinkage rates.

Consideration: Select a material early in the design process and design the mold to accommodate its specific properties.

Part Design

The geometry of the part influences the complexity of the mold and its manufacturability. Features like undercuts, sharp corners, and thin walls can make a part more difficult to mold.

Consideration: Simplify part geometry where possible and ensure features are designed with moldability in mind, such as adding draft angles to facilitate part ejection.

Mold Cavitation

The number of cavities in a mold directly impacts production efficiency and cost. More cavities mean more parts per cycle but also a higher initial cost and potentially longer cooling times.

Consideration: Balance the initial investment in the mold with the desired production volume and cost per part.

Gating System

The gate is where the molten plastic enters the mold cavity. Its design affects the appearance of the part, the strength of the weld lines, and the overall quality of the part.

Consideration: Choose the right type and location of gates to ensure optimal flow of plastic into the mold, minimizing visual defects and ensuring uniform part cooling.

Ejection System

Once cooled, the part must be ejected from the mold without damage. The design of the ejection system plays a crucial role in this.

Consideration: Design the ejection system to apply even force across the part, considering the use of ejector pins, blades, or stripper plates.

Cooling System

Proper cooling is essential for controlling cycle time and part quality. Uneven cooling can lead to warping, shrinkage, and other defects.

Consideration: Design the cooling system to achieve uniform temperature reduction across the part, using cooling channels that are strategically placed and sized.

Shrinkage

All plastic materials shrink as they cool and solidify. Inadequate consideration of shrinkage can lead to parts not meeting their dimensional specifications.

Consideration: Factor in the material’s specific shrinkage rate in the mold design to ensure the final part dimensions are accurate.

Surface Finish

The interior surface finish of the mold affects the appearance and release of the part.

Consideration: Choose a surface finish that meets the requirements for the part’s appearance and function, and ensure it’s achievable within the mold’s design.

Mold Maintenance

Molds undergo wear and tear and require maintenance to ensure longevity and consistent part quality.

Consideration: Design the mold for easy access and maintenance, considering aspects like the ease of cleaning and replacing worn components.

Working closely with experienced engineers and designers can help navigate these complexities and achieve a successful mold design.

Senses: Your Partner in Injection Molding Solutions

Senses is an ISO 9001:2015 certified plastic injection molding company, offering a comprehensive array of services including mold and part design, prototyping, small-batch production, and full-scale manufacturing. We serve a diverse range of industries, encompassing automotive, medical, and consumer electronics. Our focus is on ensuring each product we deliver meets the highest standards of quality and functionality.

For personalized solutions and expert consultation, reach out to us today at info@senseschina.com.