Precision injection molding is used to create specialized parts in industries like electronics, automotive, medical devices, optics, and more. Parts produced through precision injection molding can be used in advanced technical devices, products where small form factors are essential, or as replacements for precision metal parts. As an expert in manufacturing solutions with access to a global network of suppliers and leading-edge technology, SENSES offers customers many ways to maximize product offerings, including the use of precision injection molding.

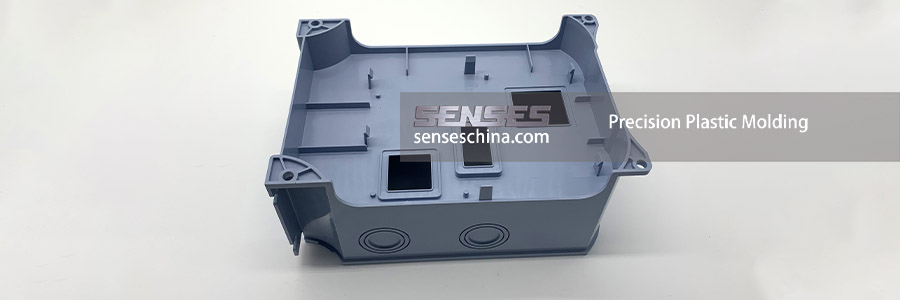

Precision Plastic Injection Molding

We specialize in high volume, precision plastic parts using scientific molding techniques, modern manufacturing equipment, and an ISO 9001:2015 certified quality management system. Additionally, we offer our customers a single source solution to all of their manufacturing needs, including engineering, design, tooling, production, decoration, assembly, packaging, and logistics. SENSES is your one-stop source for any plastic injection molded project.

Benefits of Precision Injection Molding

With the innovations in injection mold technology, businesses look to using precision injection molding for more technical applications while enjoying its benefits for a high-volume production process that is also cost effective:

- Efficient production – injection molding is faster than other molding techniques, allowing for more parts to be made from a single mold.

- Strength – the use of fillers and other material blends can give plastics strength while reducing cost.

- Complex designs – parts with high levels of detail or complex geometries can be made at high volumes.

- Reduced cost – the use of automation techniques using CNC machine solutions helps reduce labor cost while increasing production efficiency.

Precision Plastic Molding Service

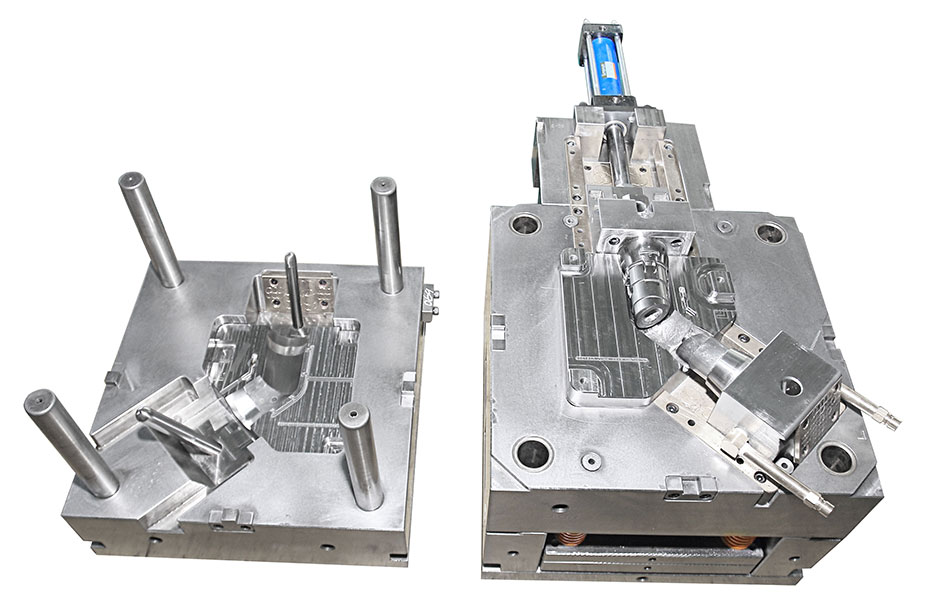

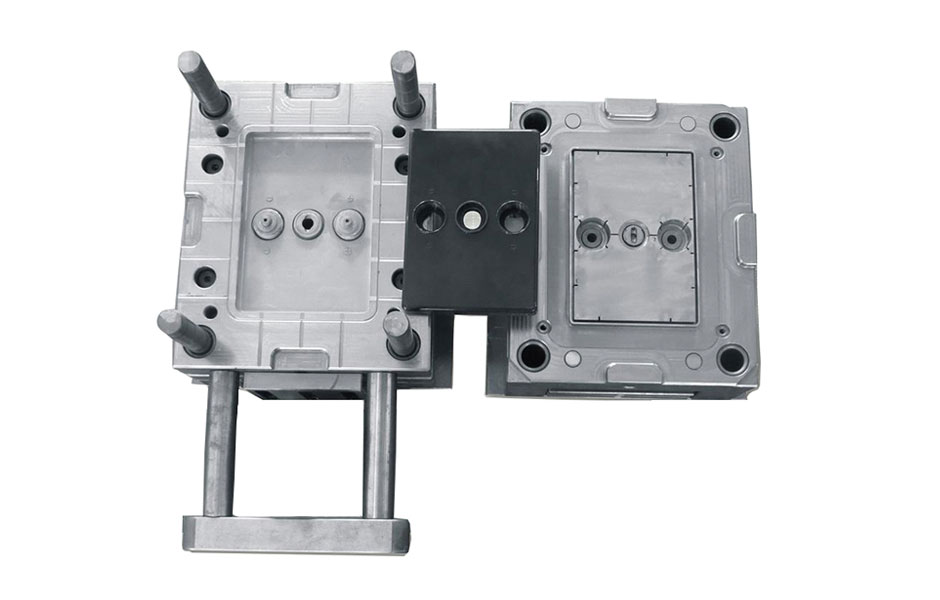

Precision Plastic Injection Mold

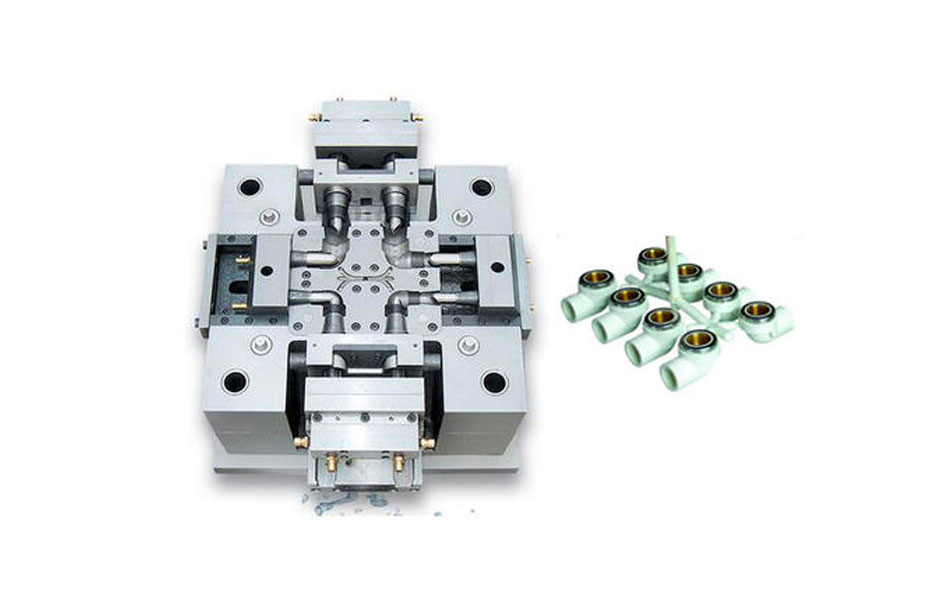

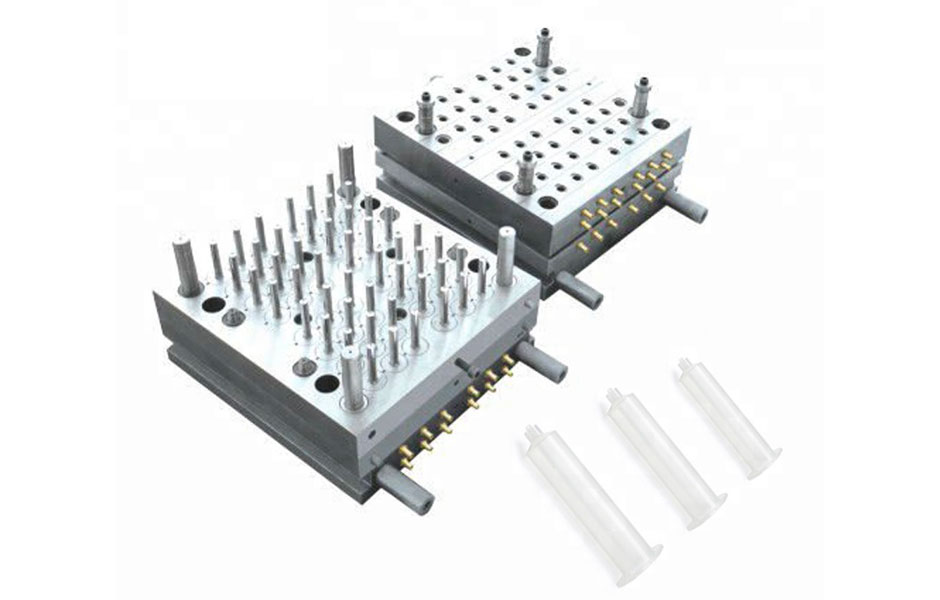

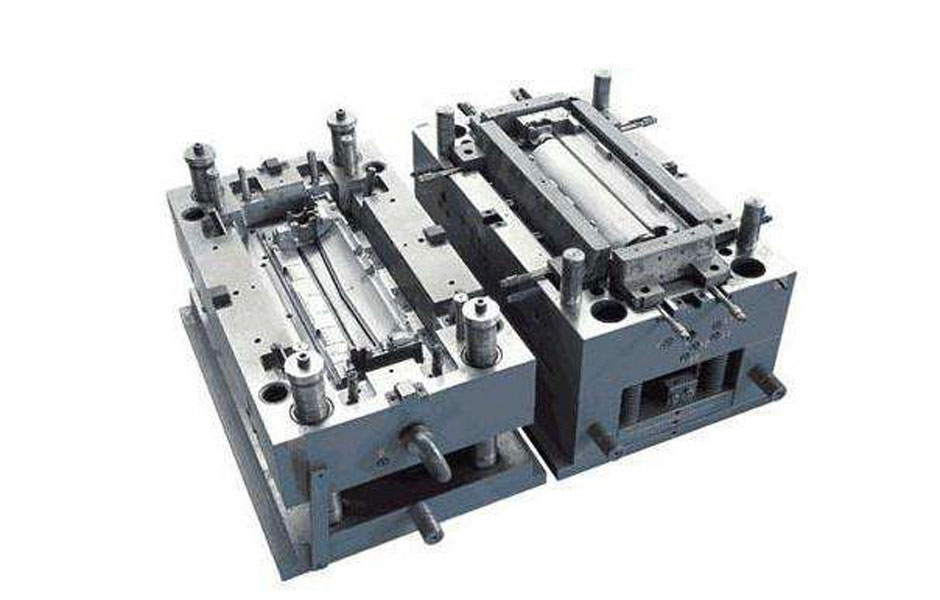

Our customers receive dedicated support for all of their validation needs and we have an experienced, expert technical team available to provide controlled sample runs with our local injection molding partner. Some of the molds we have designed and built include:

|

|

|

Automotive Injection Mould |

Appliance Injection Mould |

Precision Injection Mould |

|

|

|

Medical Device Injection Mould |

Electronic Parts Injection Mould |

Plastic Injection Moulding |

We inject over 20 years of experience into every project we take on, and our passionate, qualified and skilled group of professionals is really enthusiastic about plastic injection molding and your requirements.

Precision Plastic Molding

Contact Us for Custom Plastic Injection Molding

If your product is still in the concept stage, you only need to present your ideas, product features and appearance requirements. Our engineers will give you the best solution, recommend the most suitable materials, and help you take the lead in the market.

We are ready and looking forward to cooperate with your next project, Contact Us Now, you will be satisfied to choose us as your partner in injection mould manufacturing& injection moulding processing.

ISO 9001:2015 and IATF16949:2016 certifications are just the beginning of our commitment to quality at SENSES. Our continuous improvement program includes identifying new technologies, improving manufacturing processes and reducing waste to deliver the highest quality injection molded components.