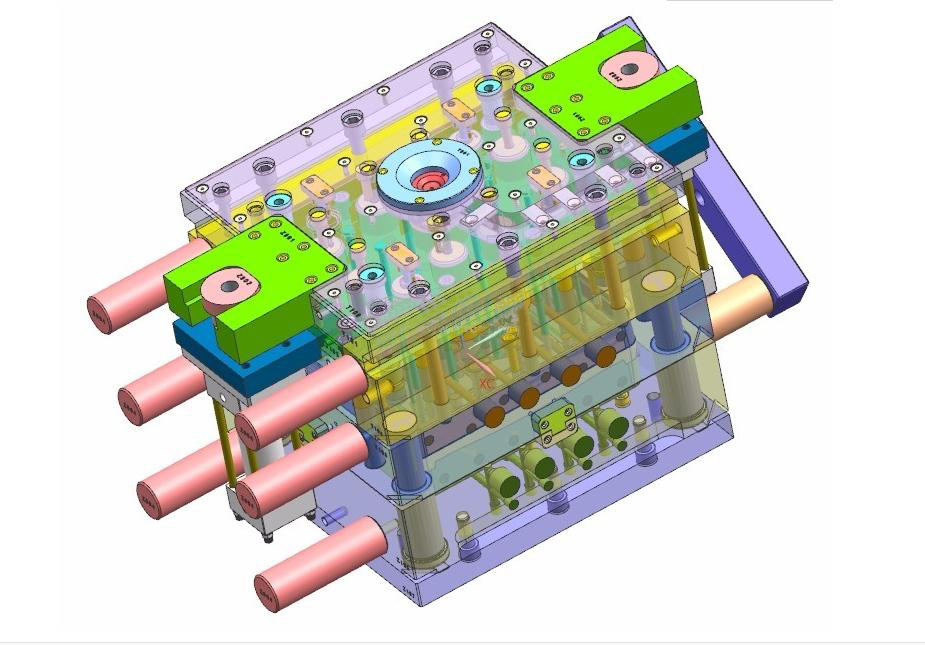

Reverse injection mould Maker in China

The structure characteristics of so-called reverse injection mould means that the core is installed on the bottom plate, so we must use the elastic pressure unloading device to unload the plastic part or waste from the core. And its cavity die is installed on the mould base, so there is the problem of how to eject the plastic part or waste parts in the cavity from the hole.

Advantages of reverse injection mould:

(1) Due to the use of elastic pressure unloading device, the plastic part is flat and the surface quality is good.

(2) Due to the use of a feeding rod to lay down the plastic part or waste from the core, the plastic part or waste does not accumulate in the core, which can reduce the rising force of the plastic part or waste to the hole. Thus, the wall thickness of the cavity can be reduced, the external size of the cavity can be reduced, and the cavity steel can be saved.

(3) Because the plastic part or waste does not accumulate in the hole of the cavity, the wear of the plastic part or waste to the edge of the mould can be reduced, the grinding times of the cavity can be reduced, so that to improve the life of cavity.

(4) Since the plastic part or waste does not accumulate in the core, it is not necessary to process the reverse face (discharge hole) of the core. It can shorten the mold manufacturing time and reduce the mold processing cost.

(5) Because the blank holder force only acts before the plate billet is not completely pulled into the core, it is suitable for the drawing of the rotating body.

Shortcomings of reverse injection mould.

(1) The structure of the reverse mould is more complex (compared with the formal mold).

(2) It is difficult to install and adjust the gap between the cavity and core. (compared with the formal die).

(3) Trouble to eject out plastic part or waste (it is best to use compressed air to blow it away).

In the selection of the mould structure, the reverse mold structure is selected only when the plastic part surface is required to be flat, the contour is more complex, the profile is asymmetric, or the blank is thin, and the rotating parts.