Plastic injection molding is extremely versatile method of producing parts and products. It is one of the preferred methods for manufacturing parts because it has multiple advantages over other methods of plastic molding. Not only is plastic injection molding simpler and more reliable, it is also extremely efficient. You should have no doubts about using this method to manufacture parts.

1. Flexibility of design

One of the key reasons behind the invention of plastic injection molding is the ability to be flexible in designs. The flexibility of the technique is one of the most remarkable features that attracts clients in need of plastic parts.

The ability to choose multiple plastics (material selection), create precise designs, be flexible in terms of color choices, the process covers it all.

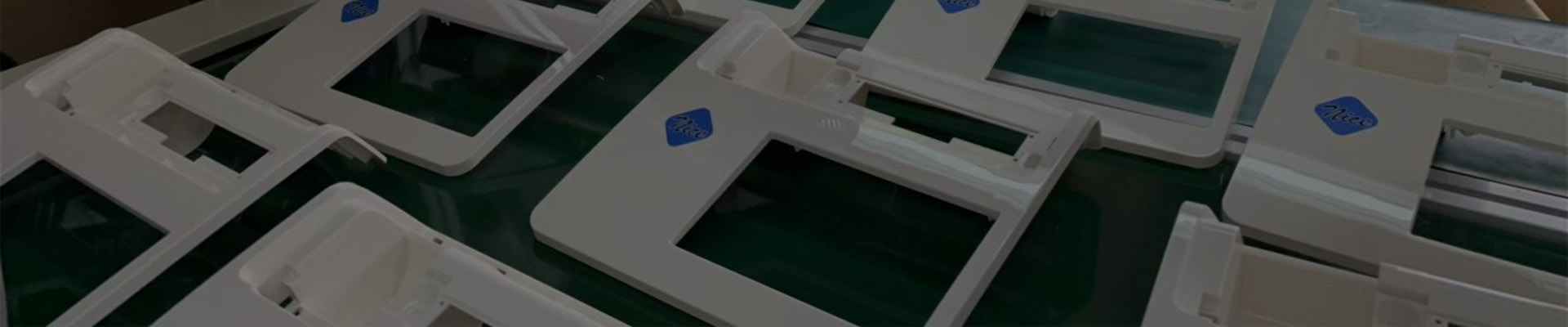

2. High Volume Production

Plastic injection molding can be used for low volume and high mix as well and low mix high volume production. Once the production process and tooling gets maturated scaling becomes incredibly easy and economical; especially if the production quantity is very large. To be sure, plastic injection molding is by far hands down the best production option for plastics. You get all you can ask for such as precision, consistency, and accuracy, and repeatability of all your parts injected from the same mold.

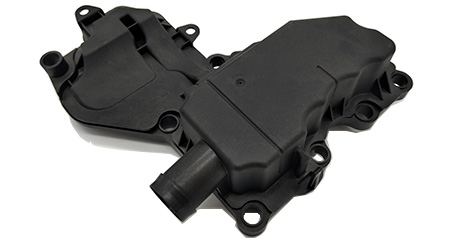

3. Ability to Use Multiple Plastic Types Simultaneously

One of the major advantages of using plastic injection molding for manufacturing parts is the ability to use different types of plastic simultaneously. This can be done with the help of co-injection molding, which takes away the worry about using a specific type of plastic.

4. Saves Cost

With advancement of plastic material development as well as the injection molding technology, the costs of plastic injection molding process has dropped dramatically. On top of that, with the development of automation and development of advanced tooling techniques, the labor input in producing a plastic part is greatly reduced. Innovative tooling technology has allowed us to produce multiple parts from a single injection molding process. The accumulated improvements in plastic materials research and injection molding technology has made injection molding application a lot more ubiquitous and consequently, less expensive.

5. Versatile Finishing

One of the key advantages of plastic injection molding compared to other low costs mass production processes is the versatility of final part finishing. There are numerous finishing available for injection molded parts such as mirror polish, special texture, sand blasting, graphics, engraving, etc.

Just take note to specify the required finishing details in the initial product development phase and have the finishing designed and incorporated into the plastic injection mold. When the plastic injection mold is fabricated with the right finishing, the parts produced would be very close to their final intended look without the need for any secondary operations.

6. Production Flexibility

If you’re looking for flexibility in the production of your plastic parts, then you’re spot on with the use of injection molding. It is all about flexibility, after all. It doesn’t matter if you are talking about specific plastic properties or the different color choices you can make. The bottom line is that injection molding process gives you a platform to tailor the production parameters according to your unique and varied needs.

7. Reduces Waste And Is Environmental Friendly

If you care about the environment like we do at Senses, then this is a good reason why you should understand the environmental benefits of injection molding. Since some or most of the scrap plastics are recycled and used again, plastic injection molding is a very waste-efficient production process as it minimizes waste and preserves the environment.

8. Consistency

If you need consistency and flexibility in all your product parts, then the use of injection molding should be the process of choice for you. When it comes to the production of plastic components, the incorporation of consistency should never be overlooked. Injection molding tend to give you the right consistency quality through the use of the same mold for each part and for advanced users there are pressure and temperature transducers available which are great in monitoring molding processes.

To be able to benefit properly from all the above-mentioned advantages of injection molding, you need to find yourself a professional and experienced complex injection molder who knows his job and knows how to do it properly. One who knows all about efficiency and optimizing reasonable designs given to him and also tackling any issue that may arise.

Finally, look for a professional molder with an established process and certifications such as the ISO 9001.

With a great technology partner equipped with appropriate experience and certified processes, injection molding would be economically superior go-to-market mass production unmatched in consistency.

we provide a total concept solution from design and tooling to production, fulfillment, and packaging. The combined effort of our designers and toolmakers results in molds that ensure quality, precision tolerances, and optimized cycle times. We have the capacity to mold parts with complex geometries and variations in wall thickness.

Our Advantage:

1. Small details make big difference. We promise:All the parts from our company have no sharp edge. All dimensions are controlled according to your drawings. Every product will be fully inspected and carefully packed to prevent the bump and rust in transit .

2. The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart.

3. Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and professional inspectors.

4. Each size of product must be tested one by one after completing production and provide quality report.

5. The most important point, we are the entity factory, not trading company. Price is the composition of the actual product quality price. Quality can guarantee more controllable higher than trading company. The price is competitive, at least reducing the trade company’s service fee.

6.We have many years of export experience,exports to the US,Europe, Japan and other countries and regions.

7.Our team are more professional. We have more reasonable price and better quality controlling than trade company. And our language ability is also diversified.

We have been serving customers in various fields, which include Commercial/Industrial Products

Custom Plastic Moulding Company

If your product is still in the concept stage, you only need to present your ideas, product features and appearance requirements. Our engineers will give you the best solution, recommend the most suitable materials, and help you take the lead in the market.

We are ready and looking forward to cooperate with your next project, Contact Us Now, you will be satisfied to choose us as your partner in injection mould manufacturing& injection moulding processing.