Senses is a plastic injection molding factory that provides full-service custom injection molding to customers. Here, we turn big ideas (yeah, like yours!) into real-life products you can hold, twist, and use every day.

We’re super proud to say we’re ISO 9001 certified. What’s that, you ask? It’s like the gold star of the manufacturing world – means we’re all about quality, consistency, and making things better, batch after batch.

Our services are like a Swiss Army knife for your designs, perfect for anything from gadgets that need to be just right, to those life-saving medical devices, and even fun stuff like your next favorite toy. We’ve got the tech, the know-how, and that extra sprinkle of care to make sure everything turns out just the way you planned. If you’re ready to kick off your next project, Contact us today to discuss your project needs.

What is Injection Molding?

Injection molding is kind of like the magic behind how a lot of everyday things are made. Imagine melting down plastic, until it’s all gooey, then squishing it into a mold that looks exactly like the part you want – that’s injection molding for you. Once the material cools down, you pop it out, and voilà, you’ve got yourself anything from a toy car to a coffee machine part.

Why is it a big deal? Well, because it’s super efficient and versatile. You can make loads of identical items quickly and not break the bank doing it. Plus, you can get really detailed with the designs, which is great for making everything from medical gadgets to your favorite phone cases. It’s a go-to method for making parts in lots of different industries because it’s reliable, fast, and keeps things looking consistent. So next time you’re holding something plastic, there’s a good chance it was made through injection molding!

How Our Injection Molding Factory Brings Your Unique Designs to Life

First up, we know that “one size fits all” doesn’t always cut it. That’s why we’ve tailored our process to be as flexible as a gymnast. Whether you have a specific vision for a new product or a custom tweak to an existing design, we’re all ears and ready to make it happen.

1. Kick-off with a Conversation: It all starts with a chat. You tell us what you need, and we listen – really listen. We want to know every little detail: the purpose of your product, your dream features, and even the challenges you’ve faced. This helps us understand not just what you want but why you want it.

2. Design and Prototyping: Once we’ve got all the info, our design team swings into action. They’ll work with you to hammer out the details, ensuring the design meets your needs while still being practical for production. Not quite there yet? No problem. We iterate and tweak until it’s just right. Then, we create a prototype, giving you a solid, touchable example of what the final product will look like.

3. Customization at Every Step: Whether it’s choosing the right materials, picking out colors, or deciding on the finish, your choices drive the process. Our job is to offer expert advice and make sure we can deliver what you’re imagining, all while keeping an eye on quality and efficiency.

4. Quality Control: Speaking of quality, it’s our middle name. Before we go full steam ahead, we’ll do a series of checks and tests to ensure everything is up to snuff and meets your standards, as well as ours.

5. Production: Once everything gets the green light, it’s go time. Our production team takes over, transforming raw materials into your finished product with precision and care. And because we know the devil’s in the details, we keep you updated with progress reports and check-ins.

6. Delivery: The final step? The final product is now ready to go wherever it’s needed, from stores to factories to maybe even your own home.

7. After-Sales Support: But our journey with you doesn’t just end when your product leaves our factory. We stand by our work and are here to ensure you’re absolutely thrilled with your order. After you’ve received your products, we’re on hand to answer any questions, resolve any issues, and provide guidance on how to get the best out of what we’ve created together. Whether it’s maintenance tips, additional modifications, or just a simple check-in, our team is dedicated to your satisfaction and ongoing success.

We believe in building lasting relationships, not just delivering orders. Your feedback drives us, your repeat business honors us, and your satisfaction is our ultimate goal. Let’s keep the conversation going and ensure your custom creations continue to meet and exceed your expectations.

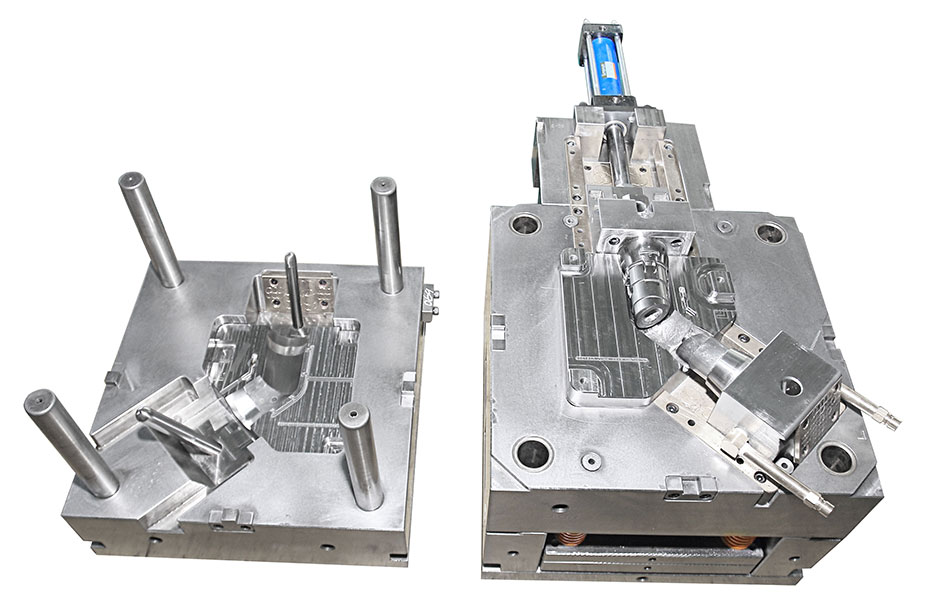

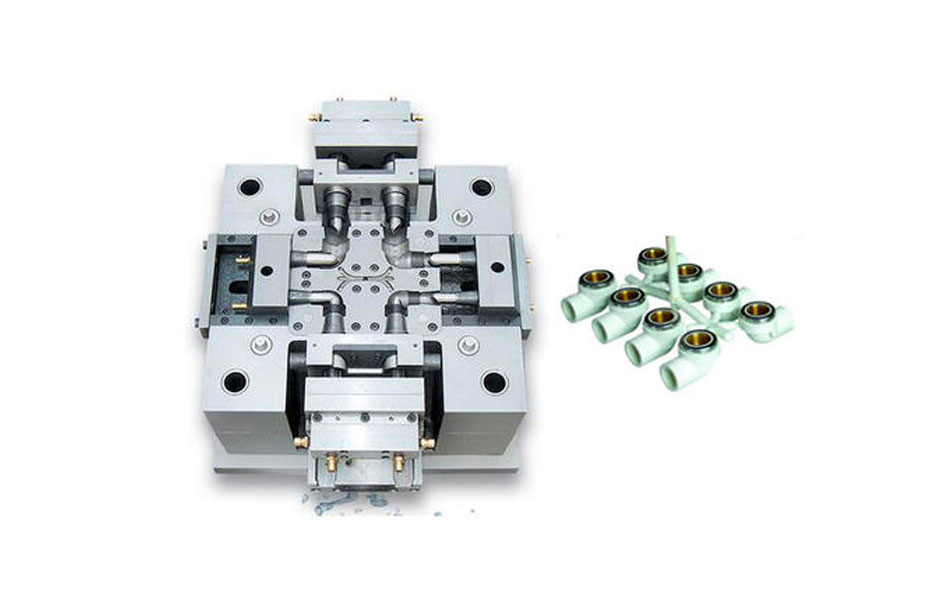

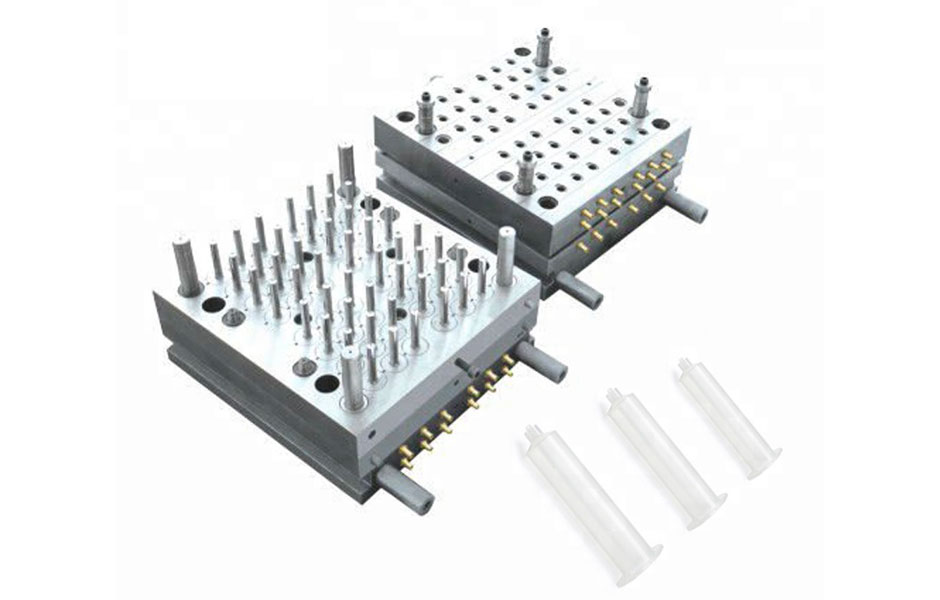

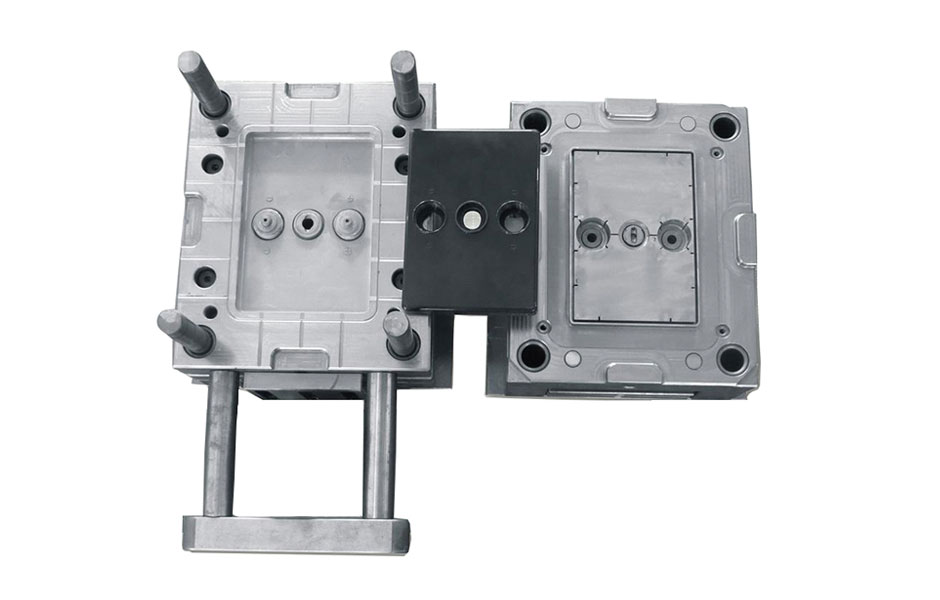

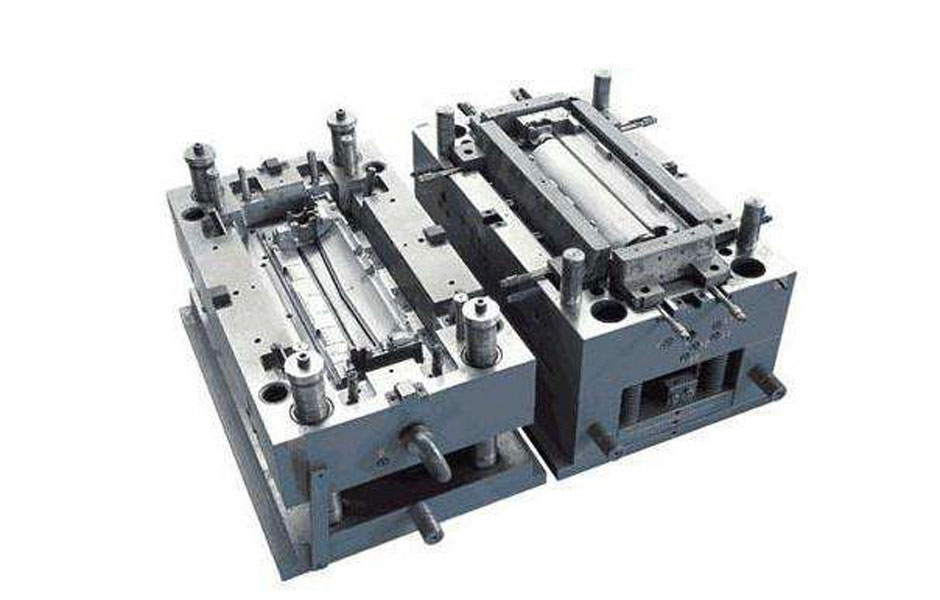

Molds & Tooling Manufacturing

If you’ve got a product in mind, we’re here to make the heart of it: the mold. Our service is all about crafting those super-important molds that shape your ideas into actual, tangible things. We’re talking about everything from tiny, intricate parts to big, bold components.

Here’s the deal: we combine the latest technology with years of hands-on experience to make sure your molds are perfect down to the last detail. Whether you’re in the automotive industry, healthcare, consumer goods, or anything in between, we’ve got your back. Our team is like a group of artists and engineers all rolled into one, dedicated to creating the mold that’s just right for your project.

|

|

|

Automotive Injection Mould |

Appliance Injection Mould |

Precision Injection Mould |

|

|

|

Medical Device Injection Mould |

Electronic Parts Injection Mould |

Plastic Injection Moulding |

Injection Molding Prototypes

Have a groundbreaking idea or a new design on the drawing board? That’s where we come in. Our Prototype Injection Molding service is all about turning your concepts into real, touchable prototypes.

Why prototype, you ask? It’s your chance to see, feel, and test your design in the real world before diving into mass production. It’s like a rehearsal for your product, ensuring everything is perfect before the big debut.

Our process is straightforward but meticulous – we focus on quality, functionality, and speed. And because we know every innovation is unique, we offer customized solutions to match your specific needs.

Quality Control Measures and Standards

Our Quality Control Commitment:

1. Material Inspection: Before anything gets rolling, we check all materials coming into our factory to ensure they meet our high standards. This means no sub-par stuff gets through the door.

2. Process Monitoring: Our eyes are everywhere – on every machine, at every stage. We monitor our injection molding processes in real time to catch any hiccups ASAP. This way, we maintain consistent quality and can tweak things on the fly if needed.

3. Precision Engineering: We invest in state-of-the-art machinery and keep them in tip-top shape.

4. Skilled Team: They’re trained up to the eyeballs in quality control standards and take personal pride in ensuring each product passes muster.

5. Rigorous Testing: Every batch, every time. Our products go through rigorous testing to ensure they meet the functional, aesthetic, and durability standards they’re supposed to. Nothing leaves the factory without a thorough check-up.

6. Continuous Improvement: Quality isn’t a one-and-done deal. We regularly review our processes, learn from any missteps, and celebrate our wins, always looking for ways to do things better.

7. Customer Feedback: Last but definitely not least, we listen to you – our customers. Your feedback is gold to us, helping us refine our products and processes even further.

We’re all about keeping it real and making sure you get what you need, quality-wise. In our factory, making things right is just how we roll. Let’s make something awesome together.

Senses: Your Partner in Injection Molding Solutions

Senses is an ISO 9001:2015 certified plastic injection molding company, offering a comprehensive array of services including mold and part design, prototyping, small-batch production, and full-scale manufacturing. We serve a diverse range of industries, encompassing automotive, medical, and consumer electronics. Our focus is on ensuring each product we deliver meets the highest standards of quality and functionality.

For personalized solutions and expert consultation, reach out to us today at info@senseschina.com.