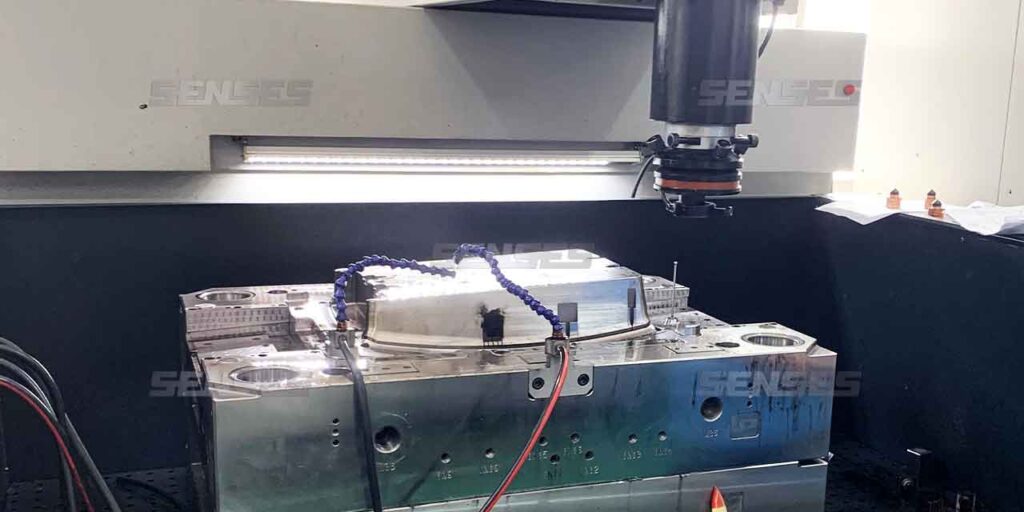

Precision injection molding is a highly specialized manufacturing process that uses precise molds to create intricate plastic parts with exacting specifications. It is an essential technique in the production of high-quality components for a wide range of industries, including automotive, medical, electronics, and consumer goods.

What is Precision Injection Molding?

Precision Injection Molding is a subset of the injection molding process that emphasizes the creation of parts with tight tolerances and exceptional detail. This method is critical for applications where the fit, function, and appearance of the plastic part are paramount.

Types of plastics suitable for precision molding

Precision injection molding is heavily dependent on the selection of the right type of plastic material, as it directly affects the quality, functionality, and appearance of the final product. Here’s a detailed look at various types of plastics suitable for precision molding:

1. Polyethylene (PE)

- Low-Density Polyethylene (LDPE): Known for its flexibility, chemical resistance, and ease of processing, making it ideal for flexible components and film products.

- High-Density Polyethylene (HDPE): Offers greater strength and rigidity, suitable for precision parts that require durability and resistance to environmental stress.

2. Polypropylene (PP)

- Chemical Resistance: Resistant to acids, alkalis, and salts, making it suitable for harsh chemical environments.

- High-Temperature Resistance: Capable of withstanding higher temperatures, ideal for automotive and electrical components.

3. Polyvinyl Chloride (PVC)

- Versatility: Available in rigid and flexible forms, suitable for a wide range of applications, including medical and construction.

- Cost-Effectiveness: Economical and easy to process, making it a popular choice for cost-sensitive projects.

4. Polystyrene (PS)

- Clarity: Offers excellent clarity, making it ideal for applications where optical transparency is required.

- Moldability: Easy to mold, allowing for the creation of complex and detailed parts.

5. Acrylonitrile Butadiene Styrene (ABS)

- Toughness: Known for its high impact resistance and toughness, suitable for parts that require durability.

- Heat Resistance: Capable of withstanding moderate heat, making it a good choice for electronic housings and automotive components.

6. Polycarbonate (PC)

- Transparency: Provides excellent optical clarity, suitable for lenses and light covers.

- High-Strength: Offers high strength and rigidity, making it ideal for precision parts that require structural integrity.

7. Nylon (Polyamide, PA)

- Chemical and Abrasion Resistance: Resistant to oils, fuels, and abrasion, suitable for mechanical parts and wear-resistant components.

- Self-Lubricating: Reduces the need for additional lubricants in moving parts.

8. Polyether Ether Ketone (PEEK)

- High-Temperature Resistance: Can withstand continuous use at high temperatures, making it ideal for aerospace and automotive applications.

- Chemical Resistance: Resistant to a wide range of chemicals, suitable for corrosive environments.

9. Polyacetal (POM)

- High Stiffness: Offers excellent stiffness and strength, making it suitable for precision gears and bearings.

- Low Friction Coefficient: Reduces friction in moving parts, improving efficiency and reducing wear.

10. Thermoplastic Elastomers (TPE)

- Flexibility: Offers a wide range of hardness and flexibility, suitable for seals, gaskets, and flexible components.

- Recyclability: Can be easily recycled and reprocessed, contributing to sustainability efforts.

Tips for designing parts for precision molding

Designing parts for precision molding requires a meticulous approach to ensure that the components meet the stringent requirements of tight tolerances and high-quality standards:

Understand Material Properties:

Familiarize yourself with the properties of the selected plastic, including its melting temperature, viscosity, and shrinkage rates.

Uniform Wall Thickness:

Design parts with uniform wall thickness to prevent uneven cooling and warping. If varying thickness is necessary, use gradual transitions.

Optimal Parting Line and Core/Cavity Design:

Place the parting line in a location that minimizes its visibility on the final product and consider the ease of part ejection.

Draft Angles:

Incorporate sufficient draft angles to facilitate part removal from the mold without causing deformation.

Rib and Goss Design:

Design ribs and gussets with a width-to-thickness ratio that provides strength without compromising mold filling or part ejection.

Gating and Runner System:

Select the appropriate type of gate (edge, pinpoint, fan, etc.) and position it to minimize material waste and provide balanced fill.

Venting:

Ensure proper venting design to allow air to escape and prevent burning or short shots.

Cooling Channels:

Integrate cooling channels in the mold design to ensure uniform cooling and reduce the risk of warpage.

Use of Mold Fill Simulation:

Utilize mold fill simulation software to analyze and optimize the flow of material into the mold cavity.

Minimize Mold Slides and Lifters:

Reduce the use of slides and lifters as they can complicate the mold and increase the potential for defects.

Consider Post-Molding Operations:

Design parts with post-molding operations in mind, such as trimming, painting, or assembly, to ensure a seamless transition from molding to finishing.

Regulatory and Industry Standards:

Ensure that the design meets all relevant regulatory and industry standards for the intended application.

Customization and Prototyping

Customization and prototyping are pivotal stages in the product development lifecycle, particularly in the context of precision injection molding. These processes allow for the fine-tuning of designs and the verification of concepts before full-scale production.

The Essence of Prototyping:

Prototyping is the creation of preliminary models or samples of a design. It is a critical phase that enables designers and engineers to validate the form, fit, and function of a part before committing to production. In precision molding, prototyping ensures that the final product will meet the stringent requirements of dimensional accuracy and performance.

Importance of Customization:

- Meeting Unique Specifications: Customization ensures that the final molded parts adhere to the unique specifications and performance criteria of the application they are intended for.

- Enhanced Functionality: Customized parts can be optimized for functionality, incorporating features that are specifically designed to meet the end-use requirements.

Prototyping Benefits:

- Design Validation: Prototyping allows for the physical validation of design concepts, ensuring that they are viable for the intended application.

- Risk Reduction: By identifying potential issues early, prototyping significantly reduces the risk of costly redesigns and production errors.

- Client Engagement: It provides a tangible means for clients to engage with the design, offering feedback and ensuring alignment with their vision.

Post-Molding Services

Post-molding services are an integral component of the injection molding process, ensuring that the final product meets the required specifications and performs optimally in its intended application.

Range of Post-Molding Services:

- Trimming and Deburring: Removing excess material and flash to ensure a clean and precise part geometry.

- Honing and Polishing: Achieving high surface finish quality through honing and polishing processes.

- Annealing: Reducing internal stresses in the molded parts through heat treatment processes.

- Assembly: Assembling multiple components into a single unit to create a complex assembly.

- Insert Molding: Incorporating metal or other material inserts into the plastic part for added strength or functionality.

- Pad Printing and Screen Printing: Applying logos, part numbers, or other markings through pad printing or screen printing techniques.

- UV Curing: Enhancing the durability of painted or coated surfaces through UV curing processes.

- Ultrasonic Welding: Joining parts together using ultrasonic waves for a seamless and strong bond.

- Hot Stamping: Adding decorative elements or metallic finishes to the surface of the plastic parts.

- Coating and Painting: Applying protective or decorative coatings and paints to improve the appearance and durability of the parts.

Why Choose Our Precision Injection Molding Services?

You Deserve Precision, We Deliver It:

At our core, we’re all about precision. We know that the little details matter, and we take pride in delivering parts that are manufactured to the exact specifications you need.

Quality You Can Count On:

Our services are backed by a commitment to quality. We use top-notch equipment and follow best practices to ensure that your parts are not just good, but great. We believe in getting it right the first time, every time.

Customization to Fit Your Needs:

We understand that no two projects are the same. That’s why we offer customization to tailor our services to your unique requirements. Whether it’s a special material, a complex design, or a specific process, we’re here to make it happen.

Fast Prototyping to Keep You Moving:

Time is of the essence, especially when you’re bringing a new product to market. Our rapid prototyping services help you iterate quickly and efficiently, getting your product from concept to reality faster.

Scalability to Grow with You:

As your needs grow, so do we. Whether you’re looking for a small batch of prototypes or a large-scale production run, our services are scalable to meet your demands without compromising on quality.

Transparent and Collaborative Process:

We believe in working closely with our clients. Open communication and collaboration are key to our process, ensuring that your vision is fully realized and that you’re in the loop every step of the way.

Experience You Can Trust:

Our team brings a wealth of experience to the table. We’ve seen it all and have the know-how to navigate even the trickiest of projects with ease. Trust our expertise to guide your project to success.

Reliable Customer Support:

Your satisfaction is our top priority. Our customer support team is on standby to address any questions or concerns you may have, ensuring a smooth and hassle-free experience.

Senses: Your Partner in Injection Molding Solutions

Senses is an ISO 9001:2015 certified plastic injection molding company, offering a comprehensive array of services including mold and part design, prototyping, small-batch production, and full-scale manufacturing. We serve a diverse range of industries, encompassing automotive, medical, and consumer electronics. Our focus is on ensuring each product we deliver meets the highest standards of quality and functionality.

For personalized solutions and expert consultation, reach out to us today at info@senseschina.com.