Are you in search of an Injection Molding Contract Manufacturing service for your plastic products? Businesses worldwide consistently turn to plastic parts for diverse applications, making injection molding companies a crucial partner for the efficient production of everyday items or customized plastic prototypes. Navigating through the myriad options in the market to find the ideal injection molder can be a daunting task.

Fortunately, your search can stop here, as some of the best injection molding companies are frequently located in China. From the initial plastic design to the final production stage, our custom injection molding service at Senses guarantees the production of high-quality, competitively priced injection molded parts with a swift turnaround time. For more information or to discuss your project needs, feel free to contact us at info@senseschina.com.

|

|

The outsourcing trend has gained significant traction, especially with the rising prominence of China’s injection contract manufacturing. This is attributed to the enhanced efficiency and cost-effectiveness associated with outsourcing plastic manufacturing processes to China. The nation’s robust manufacturing infrastructure, advanced technology, and skilled workforce contribute to the appeal of contract manufacturing for plastic products. As a result, businesses around the world are increasingly capitalizing on the advantages offered by Chinese contract manufacturers in optimizing their plastic production processes.

What is Plastic Injection Molding?

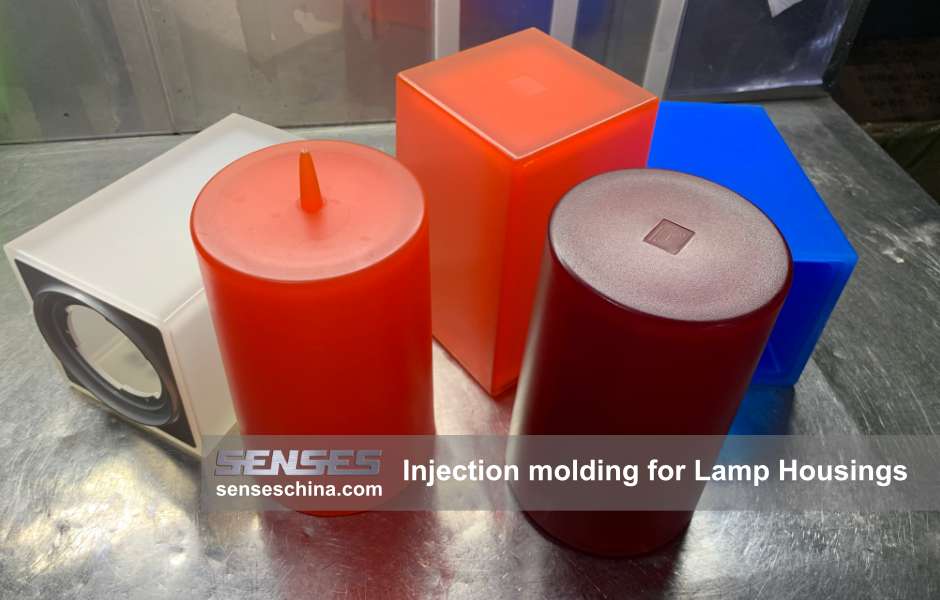

Plastic injection molding is a versatile manufacturing process that plays a pivotal role in producing a diverse range of plastic products. This method involves injecting molten plastic material into a specially designed mold, allowing it to cool and solidify into the desired shape.

|

|

| learn more to contact Senses China now! |

Plastic injection molding is not only cost-effective but also highly adaptable, capable of creating intricate designs and catering to various industries’ manufacturing needs. From small, precision components to large, complex items, the versatility of plastic injection molding makes it a preferred choice for the production of a wide array of plastic products.

Why Choose Contract Manufacturing for Injection Molding in China?

Opting to collaborate with a China Injection Molding Company offers practical advantages that can profoundly influence your business operations. Let’s delve into the reasons why this decision might be the perfect match for your manufacturing requirements.

Cost-Effective Solutions:

Working with a China Injection Molding Company offers cost-effective solutions, thanks to lower labor and production costs that can translate into tangible savings for your manufacturing budget.

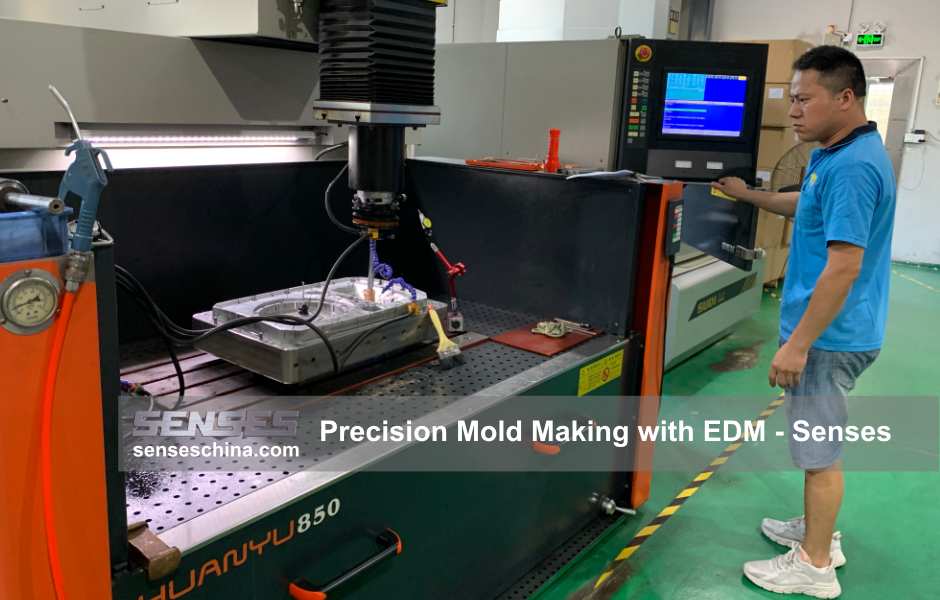

Precision through Technology:

These companies leverage cutting-edge technology and modern equipment for precise injection molding, ensuring a high level of accuracy in the manufacturing of your components.

Handling Various Production Volumes:

China’s robust manufacturing infrastructure allows for seamless handling of different production volumes, whether it’s small-scale or large-scale.

Material Options for Customization:

You’ll find a diverse range of materials for injection molding, allowing you to customize products to meet specific requirements and stay adaptable in the market.

Skilled Workforce Assurance:

Benefit from the expertise of a skilled workforce. Technicians and engineers in Chinese manufacturing companies contribute to the quality and reliability of your products.

Global Supply Chain Integration:

China’s integral role in the global supply chain ensures smooth integration, facilitating easier sourcing of raw materials and distribution of finished products on a global scale.

International Quality Standards:

Many Chinese Injection Molding Companies adhere to international quality standards, ensuring that your products meet or exceed industry expectations.

Rapid Prototyping Support:

Quickly test and refine your designs with the rapid prototyping services offered by Chinese injection molding experts, speeding up your product development cycle.

What Does Senses Offer For Injection Molding Contract Manufacturing?

Senses is your trusted partner in plastic injection molding, offering a comprehensive suite of services encompassing mold and part design, prototyping, small-batch production, and full-scale manufacturing. With an unwavering commitment to excellence, our dedicated team ensures the delivery of premium injection molding products and services at highly competitive prices.

We are ready and eager to collaborate on your next project. Contact us now, and discover the satisfaction of choosing Senses for your injection mold manufacturing and processing needs.

Our dedication to quality extends beyond our ISO 9001:2015 certifications. It marks just the beginning of our commitment. Our continuous improvement program involves the adoption of new technologies, enhancements to manufacturing processes, and waste reduction, all aimed at delivering the highest quality injection-molded components.