At Senses, our focus is on providing you with the finest services in design products, rapid prototyping, tooling design & manufacturing, injection molding services, products manufacturing, assembly.

Plastic Injection Molding

Plastic injection molding provides tight tolerances and repeatability and is ideal for high volume production of plastic molded parts. Injection molded plastic parts can be manufactured using a wide range of thermoplastic polymers, resins and elastomers, making it an ideal and cost-effective process for various industries and applications.

We have been serving customers in various fields, which include Commercial/Industrial Products:

- Auto Parts

- Casting Parts

- Cigarette Series

- Clear Parts

- Electrical Equipment

- Electronic Tools

- Soft Material Parts

- Medical Products

- Hardware Products

Plastic Parts Manufacturing

Injection Molding Process

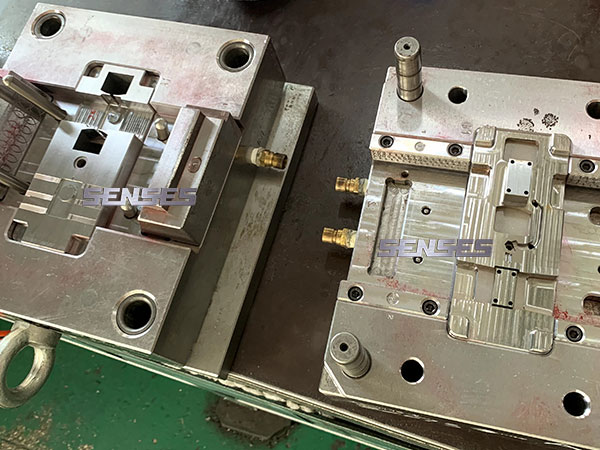

Plastic injection molding requires three primary components – an injection molding machine, a mold, and raw plastic material. Molds for plastic injection consist of high strength aluminum and steel components that have been machined to operate in two halves. The mold halves come together inside the molding machine to form your custom plastic part.

The machine injects molten plastic into the mold, where it solidifies to become the final product. The injection molding process is actually a complex process with many variables of speed, time, temperatures and pressures. The complete process cycle for making each custom part can range from no more than a few seconds to several minutes.

Senses are the injection molding experts providing a range of injection molding solutions including overmolding, insert molding and more as well as tooling and design assistance. Request a free quote to get started on your custom plastic molding project.

When you send us your 3D CAD files, our technicians will evaluate your requirements and advise the best combination of services to meet your expectations

Plastic injection molding is by far the most common way to produce large volumes of finished plastic parts for every kind of commercial and industrial use. Molten resin is injected under high pressure into the cavity of a metal die and then rapidly cooled, forming a solid shape. A single cycle to make a finished part may take anywhere from a few seconds to minutes depending on part complexity and size.

If you’re ready to start your next project, upload your product design information for a competitive injection molding quote today. If you have any questions, please feel free to contact us at senseschina@gmail.com